Method for manufacturing dacron reinforcement wire woven pattern PVC compact base coiled material

A manufacturing method and technology of reinforcing silk, which is applied in the field of flooring, can solve the problems of not feeling high-end, bad foot feeling, and dirt, and achieve the effect of comfortable foot feel, no noise, clear and natural patterns, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

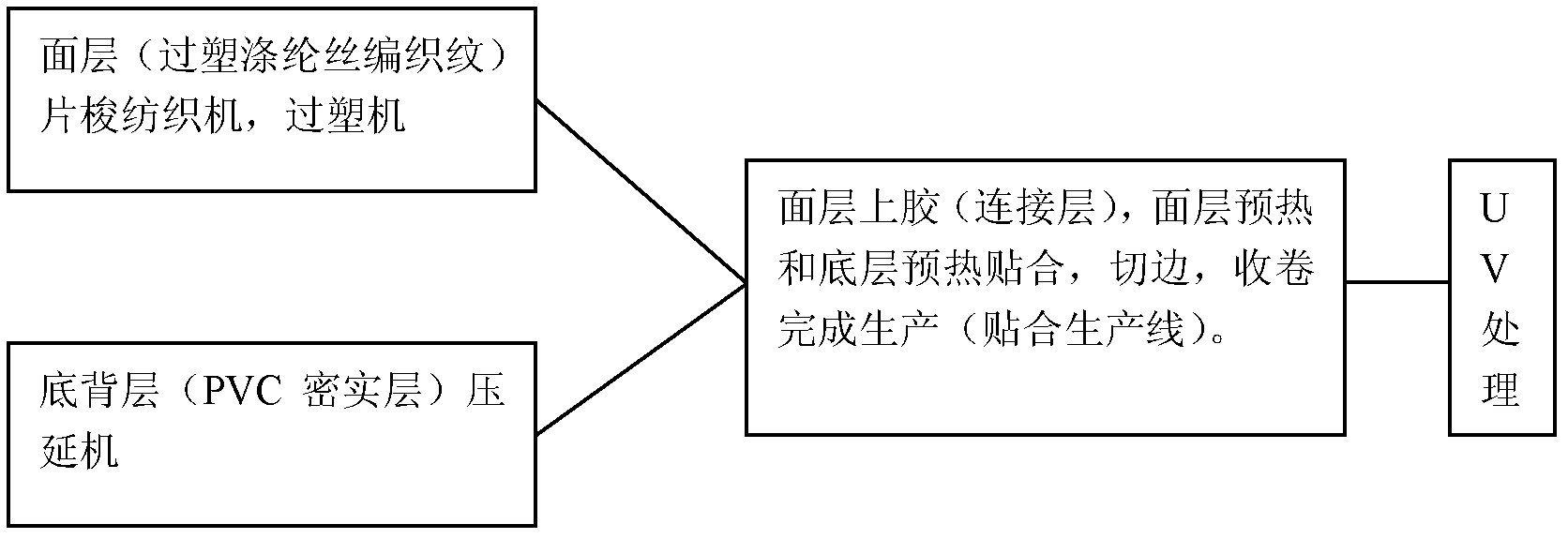

[0028] Such as figure 1 Shown, a kind of manufacture method of polyester reinforced silk braided pattern PVC compact bottom coil is characterized in that, the method comprises the following steps:

[0029] (1) Surface processing:

[0030] The high-strength polyester yarn is warped to form a multi-strand monomer 500D, and then the PVC paste is plasticized. The PVC paste formula is: polyvinyl chloride paste resin 100Kg, dioctyl phthalate 100Kg, No. 200 solvent oil 12Kg, carbonic acid Calcium 20Kg, color paste 3Kg (titanium dioxide, original blue, and heat-resistant purple are mixed in a weight ratio of 1:1:1), and stabilizer 3Kg. Then enter the 24M infrared oven for drying and plasticizing. (Temperature 170, 190, 170°C) cooled by refrigerated water, the water temperature is less than 18°C, and the warp is collected by the large shaft again, divided into warp and weft. Then it is spun on a projectile machine, which can produce weaving patterns of different colors and densities...

Embodiment 2

[0036] A method for manufacturing a polyester reinforced silk woven pattern PVC dense bottom coil, the method comprises the following steps:

[0037] (1) Surface layer processing: 100Kg of polyvinyl chloride paste resin, 100Kg of dioctyl phthalate, 12Kg of No. 200 solvent oil, 20Kg of calcium carbonate, and a color paste made of heat-resistant purple, thick black, and rose red. 3Kg, 2Kg of Ca / Zn composite heat stabilizer, 1Kg of Ba / Zn composite heat stabilizer, mixed to make PVC paste, the inside is made of high-strength polyester yarn through warping processing to form multi-strand monomer 500D, and the outside is wrapped with PVC paste The material is plasticized, enters a 24M infrared oven, and is dried, plasticized, cooled at 170°C to 190°C, and then spun on a projectile machine to obtain weaving patterns of different colors and densities;

[0038] (2) Connecting layer: Make an adhesive containing a cross-linking agent: pour 100Kg of vinyl chloride resin, 70Kg of dioctyl p...

Embodiment 3

[0043] A method for manufacturing a polyester reinforced silk woven pattern PVC dense bottom coil, the method comprises the following steps:

[0044] (1) Surface layer processing: 100Kg of polyvinyl chloride paste resin, 100Kg of dioctyl phthalate, 12Kg of No. 200 solvent oil, and 20Kg of calcium carbonate, made from thick black, rose red, medium chrome yellow, phthalocyanine green, and phthalocyanine 3Kg of color paste and 3Kg of Ca / Zn composite heat stabilizer are mixed according to the weight ratio of 1:1:0.5:0.3:0.5 to make PVC paste. Monomer 500D, the outside is covered with PVC paste and plasticized, enters a 24M infrared oven, dries, plasticizes, cools at 170 ° C ~ 190 ° C, and then spun on a projectile machine to obtain different designs and densities. weaving pattern;

[0045] (2) Connecting layer: make an adhesive containing a cross-linking agent: 100Kg of vinyl acetate resin, 70Kg of dioctyl phthalate, 1Kg of benzoyl peroxide, 2Kg of di-tert-butyl peroxide, 2Kg of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com