Cement-based thermal insulation material

A thermal insulation and cement-based technology, which is applied in the field of building materials, can solve the problem that the thermal insulation performance of building thermal insulation materials cannot meet the needs of better thermal insulation, and achieve the effect of good thermal insulation effect, easy access, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

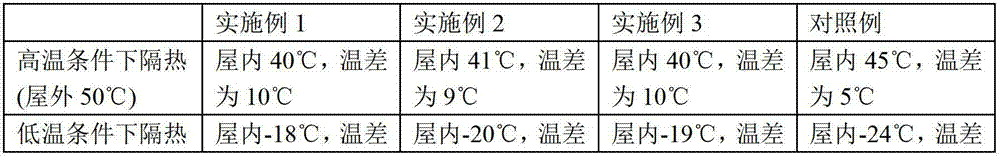

Examples

Embodiment Construction

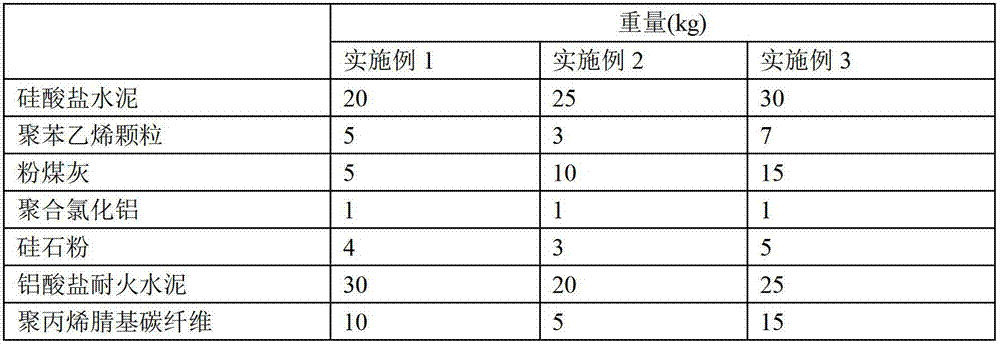

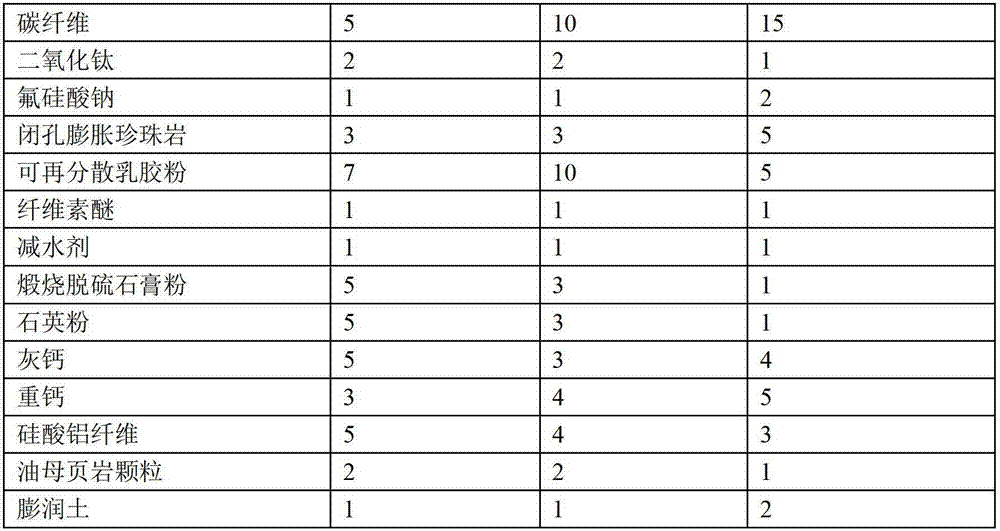

[0019] Prepare the ingredients according to the weight ratio in Table 1.

[0020] The weight proportion of table 1 embodiment 1~embodiment 3

[0021]

[0022]

[0023] The particle size of the above-mentioned closed-cell expanded perlite is 150-200 μm.

[0024] The particle size of the aforementioned titanium dioxide is 100 to 2000 nm.

[0025] The above-mentioned redispersible latex powder is an ethylene-vinyl acetate copolymer polymer.

[0026] The cellulose ether mentioned above is hydroxypropyl methylcellulose ether.

[0027] The preparation method is: take Portland cement and aluminate refractory cement, pre-disperse; then add polystyrene particles, fly ash, polyaluminum chloride, stir evenly, and make it mixture A; then take silica powder, polyacrylonitrile Base carbon fiber, carbon fiber, titanium dioxide, closed-cell expanded perlite, redispersible latex powder, calcined desulfurized gypsum powder, quartz powder, lime calcium, heavy calcium, aluminum silicate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com