Method for separating and purifying all-trans high-purity lutein esters powder

A technology for separation and purification of lutein esters, applied in the field of phytochemistry, can solve the problems of increased difficulty in manufacturing ultrasonic equipment, high requirements for supercritical extraction equipment, and unacceptable costs for users, so as to reduce labor costs and power costs, The effect of easy regeneration and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

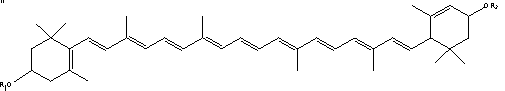

Image

Examples

Embodiment 1

[0042] At 20°C, take 50kg marigold pellets (the total content of total carotenoid-lutein diester, zeaxanthin ester and other carotenoids and their fatty acid esters is 4.0%). Feed the material at the feed inlet of the head of the extraction tube, add 50L n-hexane from the solvent inlet at the end of the continuous countercurrent ultrasonic extraction tube, and perform continuous countercurrent ultrasonic extraction. Granules to obtain 52L lutein ester extract. The extract was concentrated in vacuo at 30°C to obtain 4.0L crude extract of lutein ester. The crude extract was chromatographed through a resin column with a height-to-diameter ratio of 5:1 and a capacity of 12 L of acidic alumina. The saturated resin was desorbed with ethyl acetate at a desorption flow rate of 6 L / h to obtain 40 L of analytical solution. The stripped solution was concentrated in vacuo at 30° C. to obtain 2.2 L of lutein ester concentrate. Then slowly add 6.6L of isopropanol, slowly lower the temper...

Embodiment 2

[0044] At 30°C, take 100kg marigold granules (the total content of carotenoids-lutein diester, zeaxanthin ester and other carotenoids and their fatty acid esters is 4.2%). Feed the material at the feed port at the head of the extraction tube, add 500L cyclohexane from the solvent inlet at the end of the continuous countercurrent ultrasonic extraction tube, and perform continuous countercurrent ultrasonic extraction with an ultrasonic frequency of 40-50 KHz, continuous countercurrent ultrasonic extraction for 2-3 hours, Frame press filtration, wash the marigold granules, and obtain 510L lutein ester extract. The extract was concentrated in vacuo at 40°C to obtain 17.1L crude extract of lutein ester. The crude extract was chromatographed through a resin column with a height-to-diameter ratio of 6:1-8:1 and a neutral alumina loading capacity of 68L. The saturated resin was desorbed with ethyl acetate at a desorption flow rate of 100 L / h to obtain 270 L of analytical solution. T...

Embodiment 3

[0046] At 55°C, 100kg of marigold granules (containing total carotenoid-lutein diester, zeaxanthin ester, and other carotenoids and their fatty acid esters totaling 2.2%) were subjected to continuous countercurrent ultrasonic Feed the material at the feed inlet at the head of the extraction tube, add 1000L isopropyl ether from the solvent inlet at the end of the continuous countercurrent ultrasonic extraction tube, and perform continuous countercurrent ultrasonic extraction with an ultrasonic frequency of 80 KHz, continuous countercurrent ultrasonic extraction for 1 hour, membrane filtration and washing Chrysanthemum granules to obtain 1100L lutein ester extract. The extract was concentrated in vacuo at 50°C to obtain 20.2L crude extract of lutein ester. The crude extract was chromatographed through a resin column with a height-to-diameter ratio of 10:1 and a basic alumina loading capacity of 100 L. The saturated resin was desorbed with ethyl acetate at a desorption flow rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com