Pre-encapsulating glass syringe vacuum plugging machine

A technology for stoppering machines and syringes, which is applied in the field of vacuum stoppering machines for pre-filled glass syringes. It can solve the problems of undisclosed pre-filling of medicinal liquid, harm to the user's body, and high price of medicinal liquid, so as to avoid the escape of medicinal liquid and save Time, the effect of improving product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

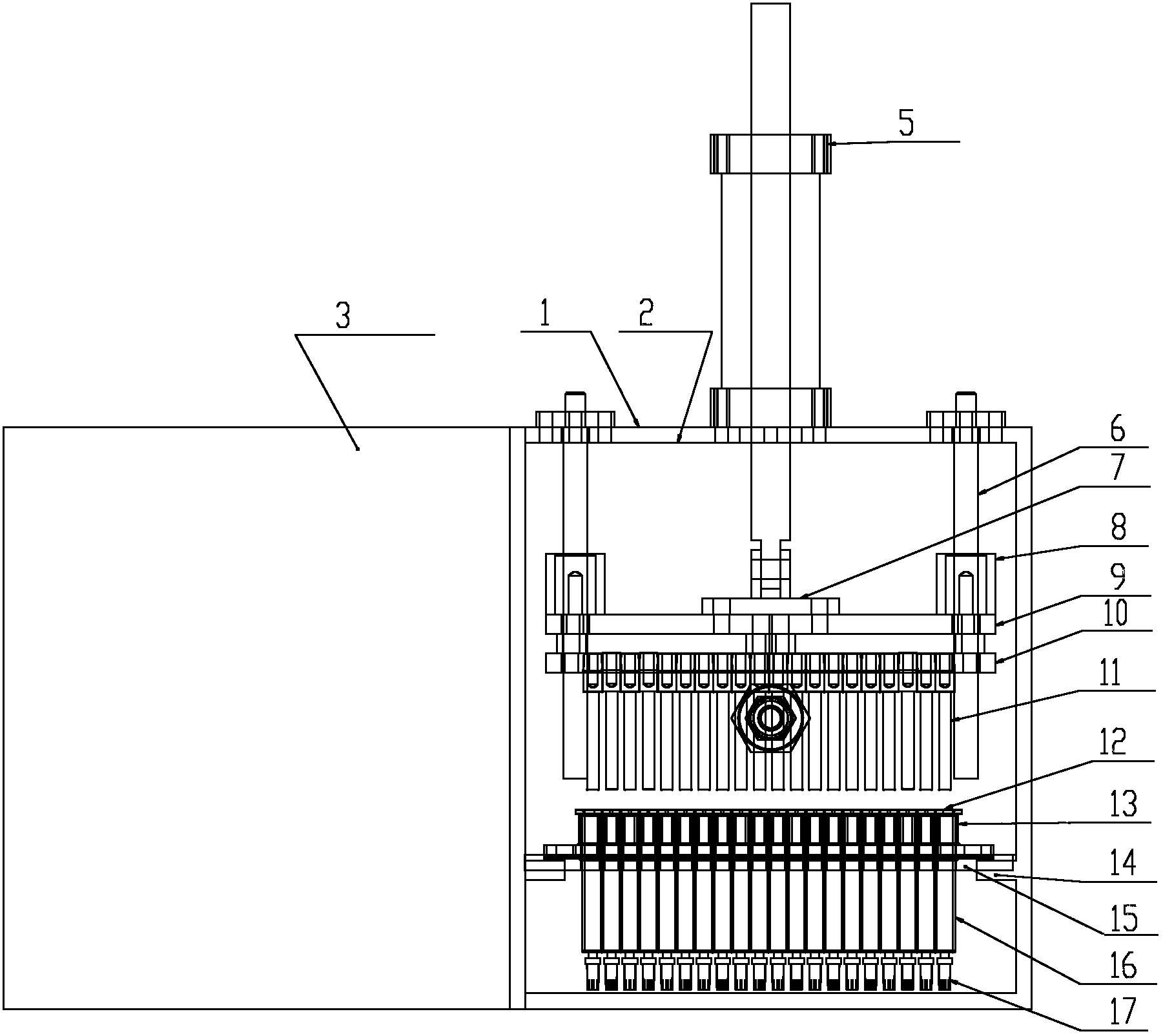

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0029] Such as figure 1 , 2 As shown, the pre-filled glass syringe vacuum stoppering machine includes a sealed box 1, and a door 3 that can be opened and closed is provided on the box 1, and the door 3 is a transparent translation door or a transparent side door. A seal 2 is provided at the contact between the door 3 and the side plate of the box body 1. A positioning tooling plate 14 is provided on the side wall of the middle and lower part of the box body 1. A plugging mechanism is arranged above the positioning tooling plate 14. The side wall of the box body 1 is There is an interface 4 connected to the external vacuum generator on the top, and the interface 4 communicates with the inside of the box body 1, and the stoppering mechanism and the vacuum generator are connected to the controller through wires.

[0030] The positioning tooling plate 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com