Dioscorea opposita peptide polysaccharide composite nutrient solution prepared from dioscorea opposita serving as raw material and by biological enzyme method and preparation method of composite nutrient solution

A technology of compound nutrient solution and biological enzyme method, which is applied in the field of yam compound nutrient solution and its preparation, can solve the problem of restricting the rapid growth of economic benefits of yam processing enterprises and foreign exchange earnings from exports, affecting the vigorous development of yam industry, and the processing of yam. To achieve the effect of preventing cardiovascular and cerebrovascular diseases, enhancing human immunity, and enhancing immune regulation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

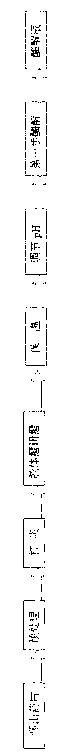

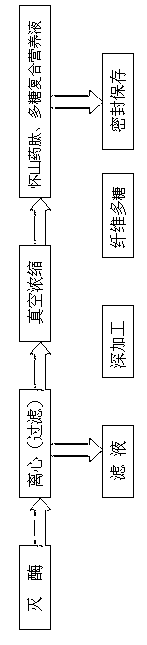

Method used

Image

Examples

Embodiment 1

[0038] (1) Material selection: select 60 kg of sulfur-free Chinese yam dry slices; requirements: no mildew, no insects, and remove impurities;

[0039] (2) Pretreatment: After soaking the Chinese yam tablets, put them into a high-pressure cooker for precooking at a temperature of 105°C for 30 minutes. Precooking can soften the tissue and gelatinize the starch, which is convenient for beating and enzymatic hydrolysis;

[0040] (3) Beating: Take out the cooked Chinese yam, put it into a mixing tank, add pure water, and carry out preliminary beating and crushing;

[0041] (4) Grinding with a colloid mill: add pure water to the preliminarily beaten slurry to make yam slurry through a colloid mill. The feed liquid passes through the colloid mill repeatedly 3 times to refine the yam slurry to obtain a yam slurry, and adjust the solid-liquid ratio to 1: 10;

[0042] (5) Adjust pH: the first step is to adjust the pH to 6.5 with compound amylase; the second step is to adjust the pH t...

Embodiment 2

[0048] (1) Material selection: select 80 kg of sulfur-free Chinese yam dry slices; requirements: no mildew, no insects, and remove impurities;

[0049] (2) Pretreatment: After soaking the Chinese yam tablets, put them into a high-pressure cooker for precooking at a temperature of 105°C for 30 minutes. Precooking can soften the tissue and gelatinize the starch, which is convenient for beating and enzymatic hydrolysis;

[0050] (3) Beating: Take out the cooked Chinese yam, put it into a mixing tank, add pure water, and carry out preliminary beating and crushing;

[0051] (4) Grinding with a colloid mill: add pure water to the beaten slurry to make yam slurry through a colloid mill, and the material liquid passes through the colloid mill repeatedly for 3 times to refine the yam slurry to obtain a yam slurry, and adjust the solid-liquid ratio to 1:12 ;

[0052] (5) Adjust pH: the first step is to adjust the pH to 7.0 with compound amylase; the second step is to adjust the pH to ...

Embodiment 3

[0058] (1) Material selection: select 100 kg of sulfur-free Chinese yam dry slices; requirements: no mildew, no insects, and remove impurities;

[0059] (2) Pretreatment: After soaking the Chinese yam tablets, put them into a high-pressure cooker for precooking at a temperature of 105°C for 30 minutes. Precooking can soften the tissue and gelatinize the starch, which is convenient for beating and enzymatic hydrolysis;

[0060] (3) Beating: Take out the cooked Chinese yam, put it into a mixing tank, add pure water, and carry out preliminary beating and crushing;

[0061] (4) Grinding with a colloid mill: add pure water to the beaten slurry to make a yam slurry through a colloid mill, and the material liquid passes through the colloid mill repeatedly for 3 times to refine the yam slurry to obtain a yam slurry, and adjust the solid-liquid ratio to 1:15 ;

[0062] (5) pH adjustment: the first step is to adjust the pH to 6.0 with compound amylase; the second step is to adjust the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com