Method for preparing graphene/carbon nanotube hybrid in hierarchical structure

A carbon nanotube and hierarchical structure technology, applied in the field of new energy materials, can solve the problems of harsh atmosphere conditions, affecting the performance of hybrids, and destroying the graphene structure, and achieves the effects of environmental friendliness, low cost, and large effective specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

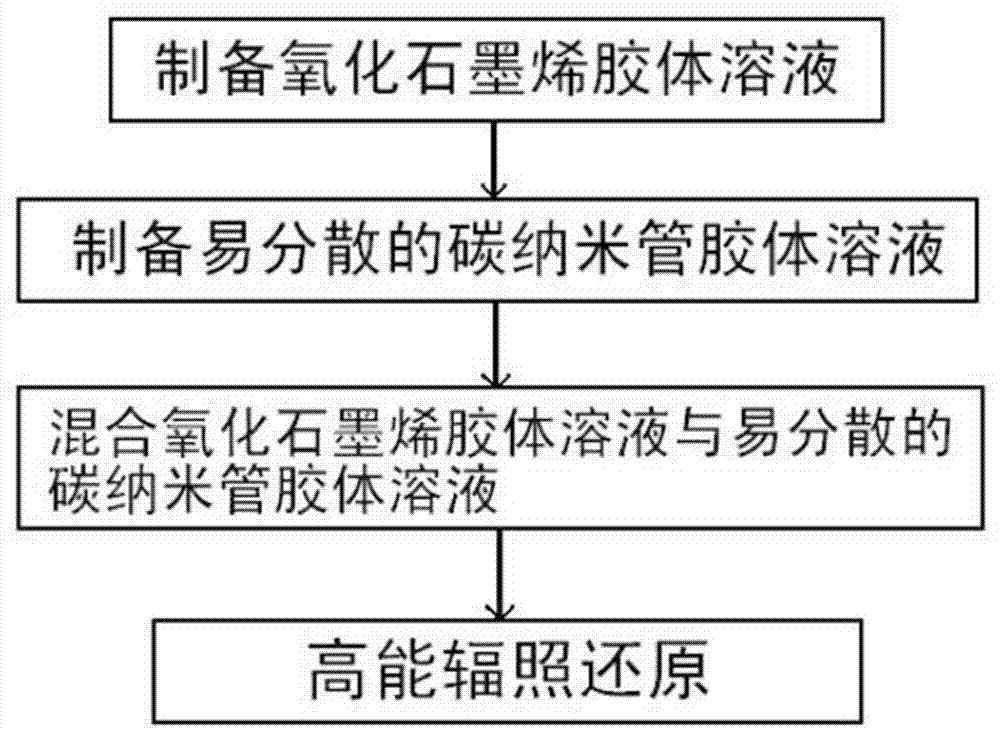

[0031] A preparation method of hierarchical structure graphene / carbon nanotube hybrid, comprising the following steps:

[0032] (1) Preparation of graphene oxide colloidal solution

[0033] Disperse graphite oxide in deionized water, control the concentration of graphite oxide to 6 mg / mL, add a small amount of ammonia water dropwise to adjust the pH value of the solution between 9 and 11, stir at room temperature for 48 hours, and remove unstripped oxide by low-speed centrifugation. Graphite, obtain graphene oxide colloidal solution.

[0034] (2) Preparation of easily dispersible carbon nanotube colloidal solution

[0035] Put 2 grams of carbon nanotubes into 98% sulfuric acid (H 2 SO 4 ) and nitric acid (HNO 3 ) in the mixed acid, H 2 SO 4 with HNO 3 The volume ratio was 3:1, the concentration of carbon nanotubes in the mixed acid solution was controlled to 10 mg / mL, mechanically stirred at 60°C for 48 hours, ultrasonically treated for 4 hours, and then washed with dei...

Embodiment 2

[0075] A preparation method of hierarchical structure graphene / carbon nanotube hybrid, comprising the following steps:

[0076] (1) Preparation of graphene oxide colloidal solution

[0077] Disperse graphite oxide in deionized water, control the concentration of graphite oxide to 10 mg / mL, add a small amount of ammonia water dropwise to adjust the pH value of the solution between 9 and 11, stir at room temperature for 72 hours, and remove unstripped oxide by low-speed centrifugation. Graphite, obtain graphene oxide colloidal solution.

[0078] (2) Preparation of easily dispersible carbon nanotube colloidal solution

[0079] Put 1 gram of carbon nanotubes into 98% sulfuric acid (H 2 SO 4 ) and nitric acid (HNO 3 ) in the mixed acid, H 2 SO 4 with HNO 3 The volume ratio was 3:1, the concentration of carbon nanotubes in the mixed acid solution was controlled to 5 mg / mL, mechanically stirred at 60°C for 24 hours, ultrasonically treated for 4 hours, and then washed with deio...

Embodiment 3

[0088] A preparation method of hierarchical structure graphene / carbon nanotube hybrid, comprising the following steps:

[0089] (1) Preparation of graphene oxide colloidal solution

[0090] Disperse graphite oxide in deionized water, control the concentration of graphite oxide to 0.1 mg / mL, add a small amount of ammonia water dropwise to adjust the pH value of the solution between 9 and 11, stir at room temperature for 48 hours, and remove unstripped oxide by low-speed centrifugation. Graphite, obtain graphene oxide colloidal solution.

[0091] (2) Preparation of easily dispersible carbon nanotube colloidal solution

[0092] Put 5 grams of carbon nanotubes into 98% sulfuric acid (H 2 SO 4 ) and nitric acid (HNO 3 ) in the mixed acid, H 2 SO 4 with HNO 3 The volume ratio was 3:1, the concentration of carbon nanotubes in the mixed acid solution was controlled to 100 mg / mL, mechanically stirred at 60°C for 72 hours, ultrasonically treated for 6 hours, and then washed with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com