A kind of capacitive touch screen with flexible transparent conductive film and preparation method thereof

A transparent film, flexible conductive technology, applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve the problems of glass-type capacitive touch screens such as thick thickness, heavy weight, and inability to curl, etc., to achieve widening Through the range of the spectrum, reduce reflection, and have the effect of high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

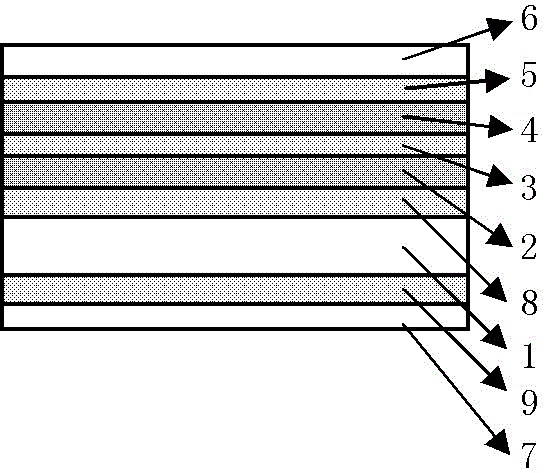

[0027] see figure 2 as shown,

[0028] 1. On both sides of a PET film substrate 1 with a thickness of 188 μm, acrylic resin is coated by wet printing. After coating, it is dried by hot air and hardened by ultraviolet light, and the first resin film layer 8 or the second resin film layer 9 with a thickness of about 5 μm is formed on both sides of the PET film substrate.

[0029] 2. On the surface of the first resin film layer 8, the first Nb with a thickness of 5 nm is formed by means of reactive magnetron sputtering coating 2 o 5 Thin film layer 2. Next, in the first Nb 2 o 5 The first Nb of 15nm is formed on the thin film layer 2 by reactive magnetron sputtering coating method 2 Ox (02 Ox (02 Thin film layer 4, in the first SiO 2 A first SiOy (0<y<2) thin film layer 5 with a thickness of 20 nm is formed on the thin film layer 4 . Finally, on the first SiOy (0<y<2) thin film layer 5, use the same method to form a first ITO thin film layer 6 with a thickness of 25 nm, ...

Embodiment 2

[0031] Embodiment 2 differs from Embodiment 1 in that: the first Nb 2 o 5 Thin film layer 2, the first Nb 2 Ox (02 Thicknesses of the thin film layer 4 , the first SiOy (0

Embodiment 3

[0033] Embodiment 3 differs from Embodiment 1 in that: the first Nb 2 o 5 Thin film layer 2, the first Nb 2 Ox (02 Thicknesses of the thin film layer 4 , the first SiOy (0

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com