Monocrystalline silicon zone melting drawing furnace control system

A technology of control system and silicon area, applied in the direction of single crystal growth, self-area melting method, crystal growth, etc., can solve problems such as unstable stretching process, stuck, and product pass rate drop, so as to ensure long-term trouble-free operation , Protect the safety limit and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

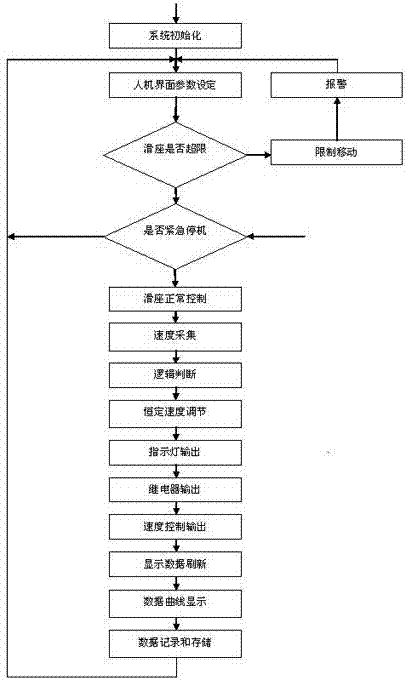

[0046] The purpose of the present invention is to promote the overall technical level of domestic single crystal zone melting furnaces, and provide a control device with complete functions, strong applicability, stability and reliability. Its digital speed regulation and fixed-speed closed-loop adjustment system can control the change of the crystal diameter of the single crystal rod within ±0.3mm, improving the yield of single crystal.

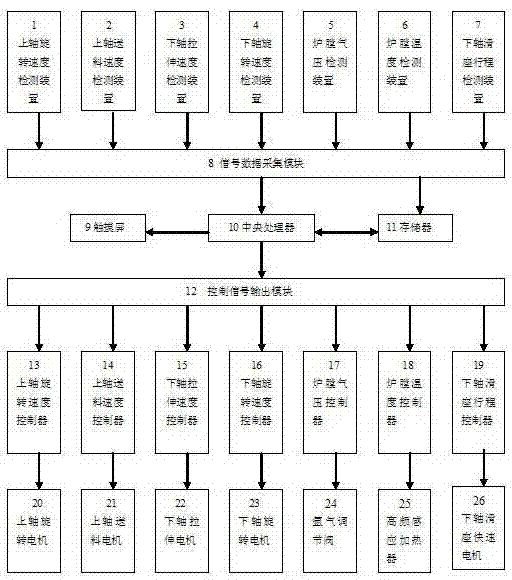

[0047] see figure 2 , the single crystal silicon zone melting and stretching furnace control system includes a signal detection device, a main controller, a control object and its actuator part, wherein:

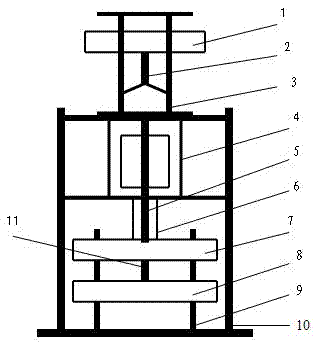

[0048] The signal detection device includes an upper shaft rotation speed detection device 1, an upper shaft feeding speed detection device 2, a lower shaft rotation speed detection device 4, a lower shaft stretching speed detection device 3, a furnace temperature detection device 6, a furnace air pressure detection device 5, and a lower s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com