Process for producing thermoplastic elastomer composition

A thermoplastic elastomer and composition technology, applied in the field of thermoplastic elastomer composition production, can solve the problems of poor stability of metal halide feed, fluctuation of metal halide feed rate, metal halide segregation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] The present invention is described in more detail below by way of examples.

[0055] Raw materials and evaluation methods used in the following examples are as follows.

[0056] [raw materials to use]

[0057] Components (A), (E): by adding 100 parts by weight of ethylene-propylene-5-ethylene-2-norbornene copolymer rubber (Mooney viscosity (ML 1+4 Oil-extended rubber prepared by adding 100 parts by weight of paraffinic mineral oil to 100° C.) = 63, ethylene unit content = 66% by weight, and 5-ethylidene-2-norbornene unit content = 4% by weight

[0058] Component (B): polypropylene resin (polypropylene homopolymer, produced by Sumitomo Chemical Co., Ltd., trade name: NOBLEN D101, MFR (230° C., 21.18 N) = 0.7 g / 10min)

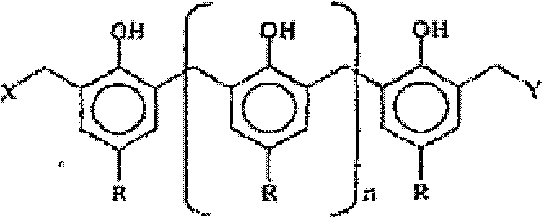

[0059] Component (C): Alkylphenol aldehyde condensate (manufactured by Taoka Chemical Co., Ltd., trade name: Tackirol 201)

[0060] Component (D): tin protochloride dihydrate (manufactured by Nihon Kagaku Sangyo Co., Ltd.)

[0061] Component (E): Par...

Embodiment 1

[0086] In the twin-screw extruder, continuously feed 62 parts by weight of oil-extended rubber, 24 parts by weight of polypropylene resin pellets (which are ground), 14 parts by weight of paraffin series mineral oil, 0.1 part by weight of phenols Antioxidant powder, 1.5 parts by weight of alkylphenol formaldehyde condensation product powder, and the mixture of polypropylene powder and stannous chloride dihydrate powder of 2.4 parts by weight (the polypropylene powder of 2.0 parts by weight, the dihydrate chloride of 0.4 parts by weight stannous powder), followed by dynamic heat treatment at 200±10° C. in order to obtain a thermoplastic elastomer composition. The feed stability of stannous chloride dihydrate is good.

Embodiment 2

[0088] In addition to using a mixture of 2.4 parts by weight of polyethylene powder and stannous chloride dihydrate powder (2.0 parts by weight of polyethylene powder; 0.4 parts by weight of stannous chloride dihydrate powder) instead of 2.4 parts by weight of polypropylene powder and dihydrate The mixture of stannous chloride hydrate powder implements each program step in the same manner as in Example 1. The feed stability of stannous chloride dihydrate is excellent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com