Organosilicon-modified waterborne polyurethane composite material and applications thereof

A technology of water-based polyurethane and composite materials, applied in the direction of polyurea/polyurethane coatings, polyurea/polyurethane adhesives, paper coatings, etc., can solve the problems of large specific surface area, high thermal stability, low density, etc., and achieve a simple process. , The effect of improving hardness and heat resistance, and improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

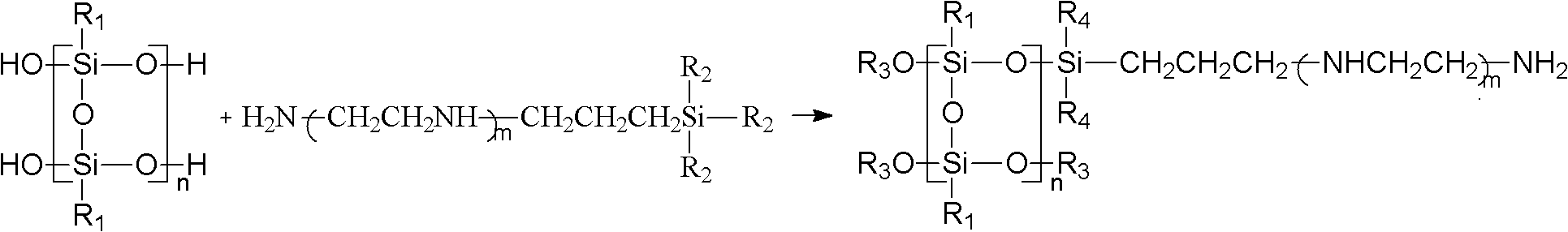

[0068] 1) According to the ladder polysilsesquioxane (R in the aforementioned ladder polysilsesquioxane structure) 1 is phenyl; n is 40): aminosilane coupling agent (R in the aforementioned aminosilane coupling agent structure 2 for OCH 3 , m is 3): the weight ratio of tetramethyl ammonium hydroxide: ether is the ratio of 100: 50: 2.5: 400, the above materials are mixed, and the temperature is 50 ° C to carry out stirring reaction for 24 hours; Tetramethylamine hydroxide, to obtain amino-containing ladder polysilsesquioxane (R 1 is phenyl; n is 40);

[0069] 2) According to the weight ratio of toluene-2,4-diisocyanate: polycaprolactone diol: 2,2-dimethylolpropionic acid: dibutyltin dilaurate: acetone is 100:350:30:2 The ratio of: 400, the above materials are mixed evenly, and the reaction is carried out at a temperature of 60 ° C for 6 hours, and after the reaction is completed, a hydrophilic polyurethane prepolymer whose end group is -NCO is obtained;

[0070] 3) The hydr...

Embodiment 2

[0077] Basically the same as Example 1, except that the hydrophilic polyurethane prepolymer whose end group is -NCO, the amino group-containing ladder polysilsesquioxane (R 1 is phenyl; n is 40), the weight ratio of dibutyltin dilaurate and acetone was changed from 100:10:1:100 to 100:0.2:1:100.

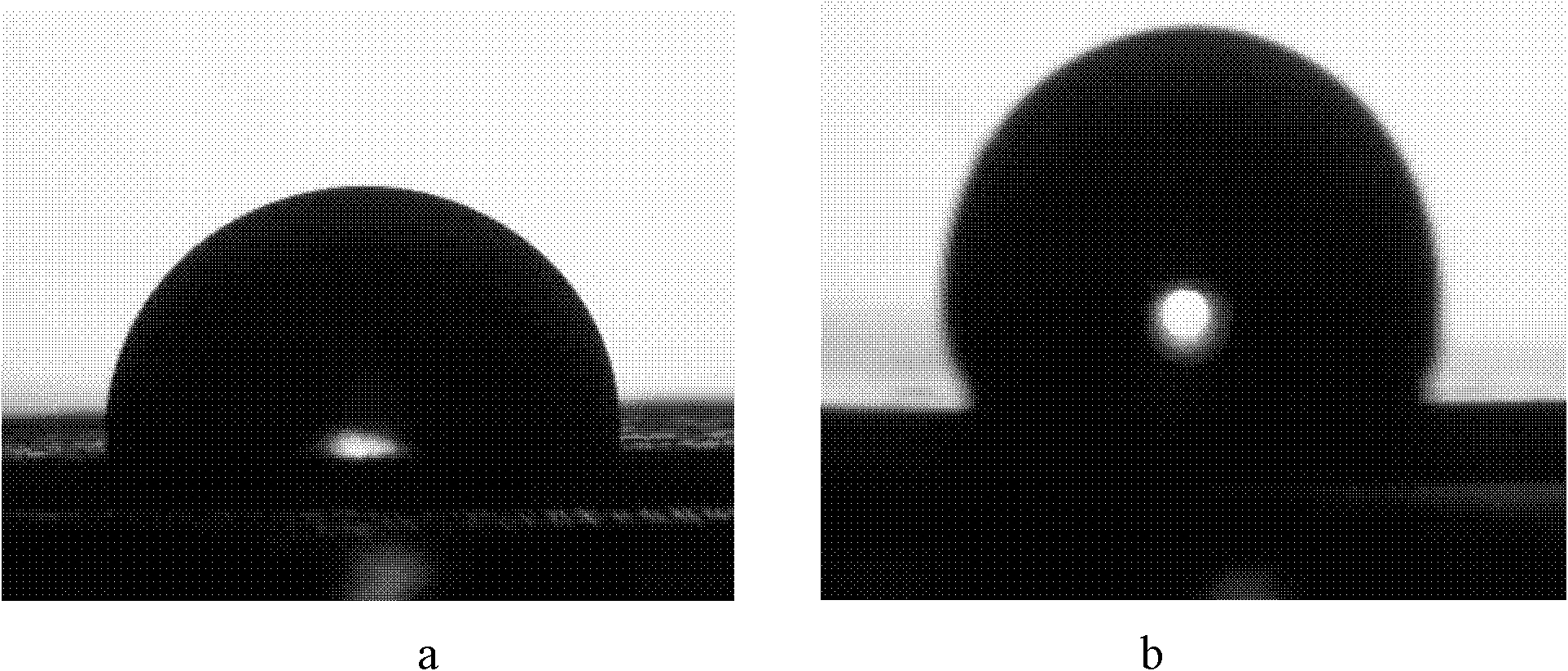

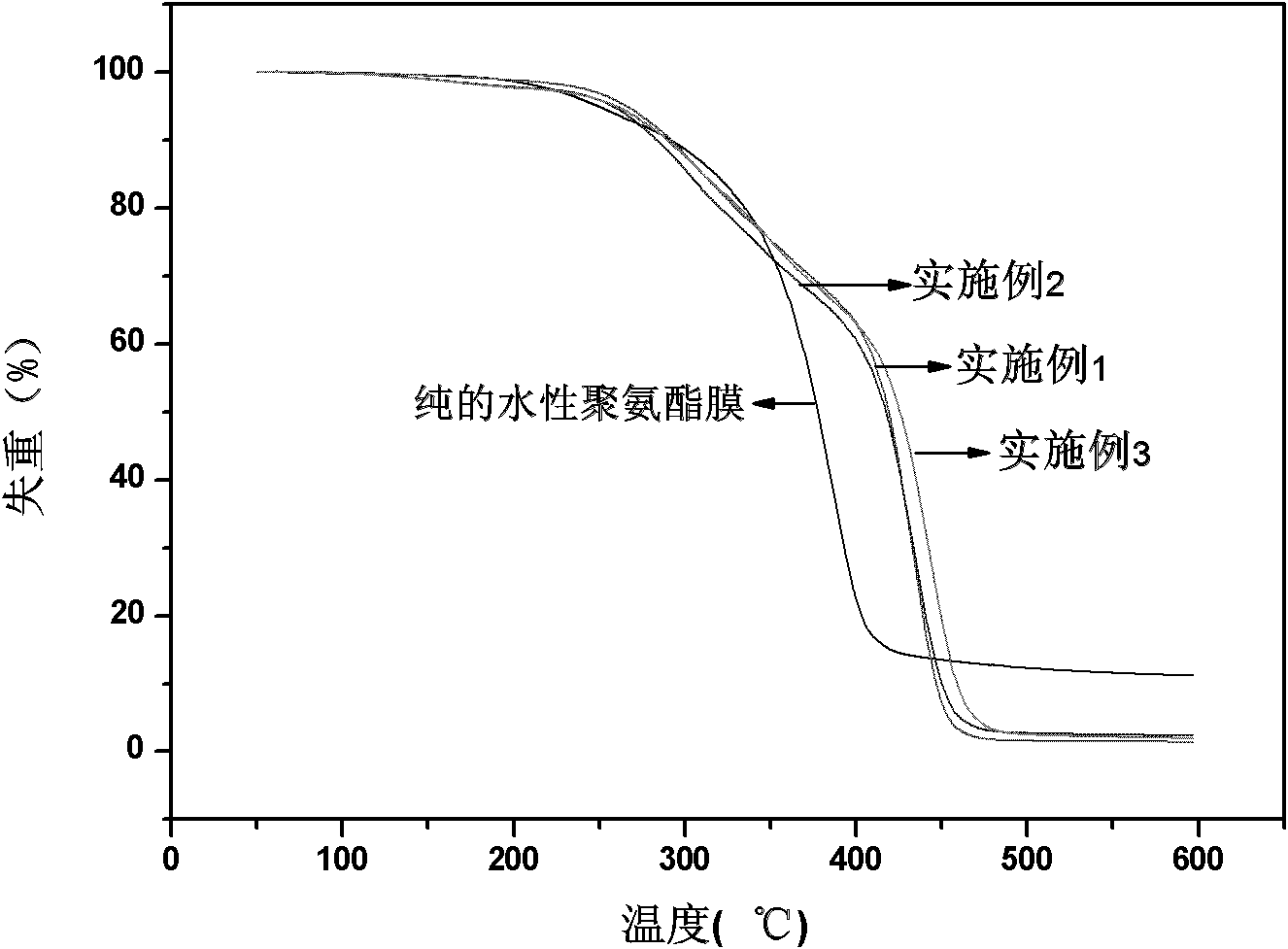

[0078] The properties of the obtained composite material are similar to those in Example 1, and it can be used as a surface coating material for wood, paper, etc., or as a finishing agent for fabrics and leather, or as a finishing agent for fabrics, or as an adhesive. The coating properties of the composite material are shown in Table 1, and the thermal weight loss curve is shown in Table 1. figure 2 shown.

Embodiment 3

[0080] Basically the same as Example 1, except that the hydrophilic polyurethane prepolymer whose end group is -NCO, the amino group-containing ladder polysilsesquioxane (R 1 is phenyl; n is 40), the weight ratio of dibutyltin dilaurate and acetone was changed from 100:10:1:100 to 100:20:1:100.

[0081] The properties of the obtained composite material are similar to those in Example 1, and it can be used as a surface coating material for wood, paper, etc., or as a finishing agent for fabrics and leather, or as a finishing agent for fabrics, or as an adhesive. The coating properties of the composite material are shown in Table 1, and the thermal weight loss curve is shown in Table 1. figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com