Method for preparing graphene oxide base porous film by using metal hydroxide nanowires and graphene oxide, and application of graphene oxide base porous film

A porous film and graphene technology, applied in chemical instruments and methods, copper oxide/copper hydroxide, membrane technology, etc., can solve the problems of low separation efficiency and difficulty of graphene oxide film, achieve superior mechanical properties, good The effect of separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

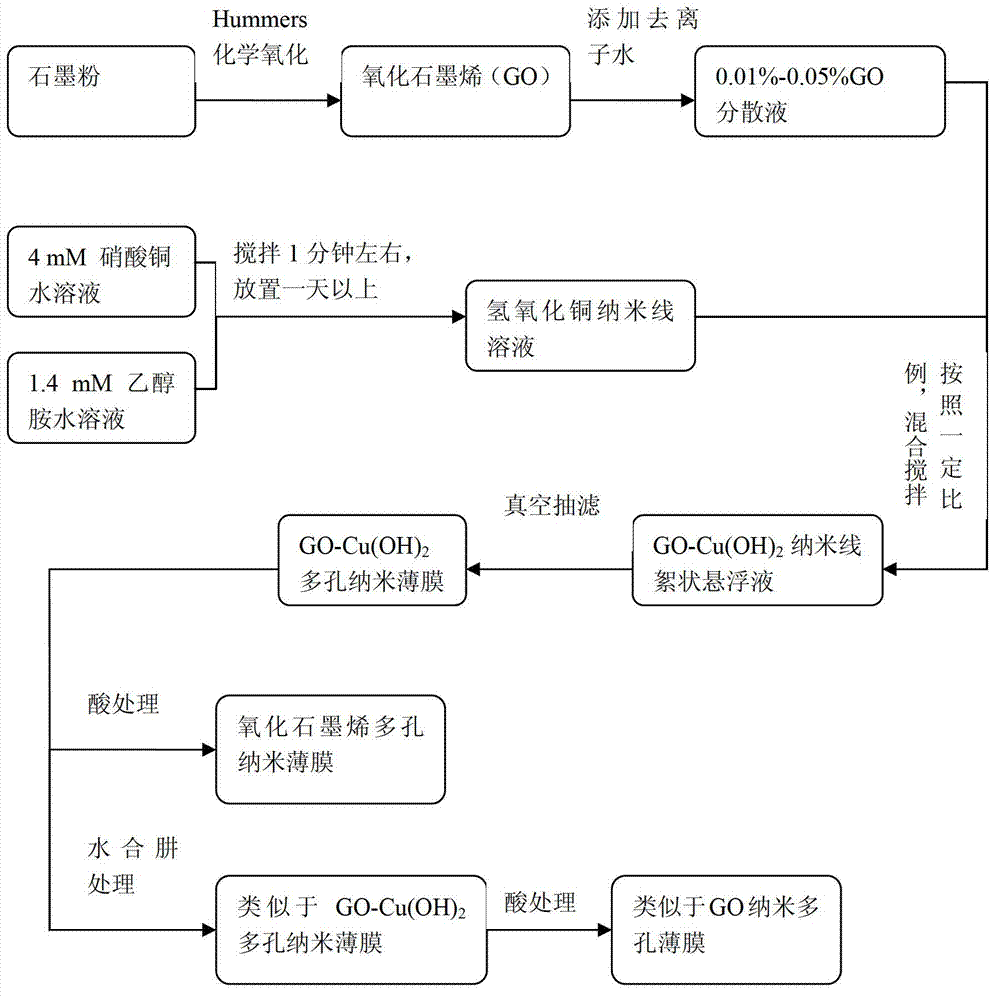

Method used

Image

Examples

Embodiment 1

[0060] 1) Ultrasonic dispersion of graphene oxide to obtain a graphene oxide dispersion with a mass percentage concentration of 0.005%, for use;

[0061] 2) The same volume of 4 mM copper nitrate aqueous solution and 1.4 mM ethanolamine aqueous solution were mixed evenly under magnetic stirring, and then stood for 1 day to generate Cu(OH) 2 nanowire solution;

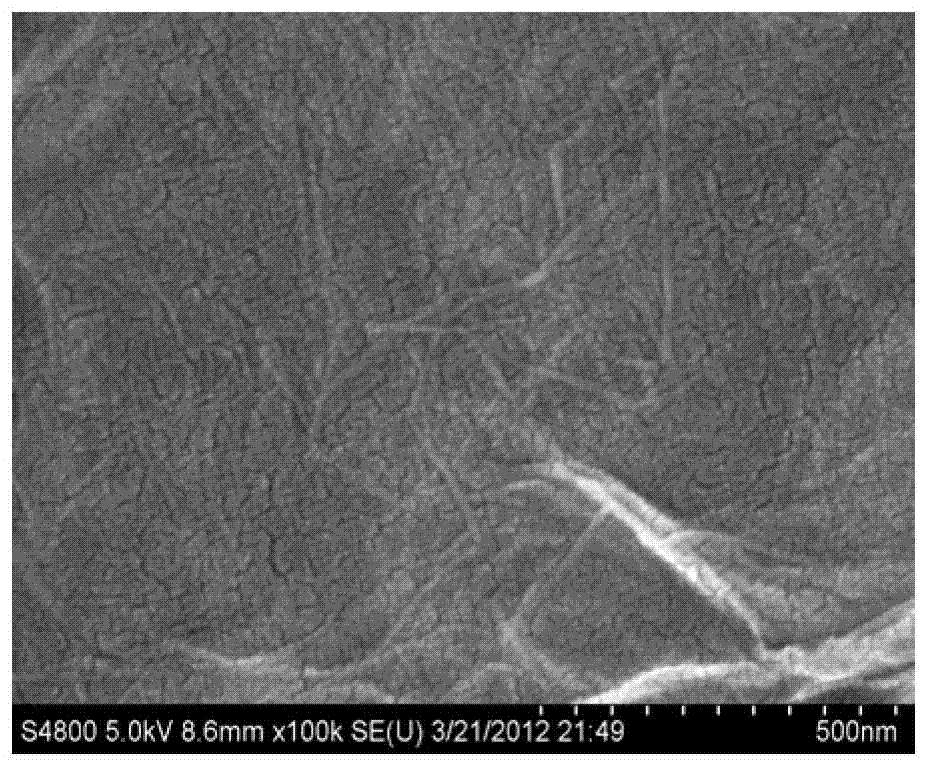

[0062] 3) The graphene oxide dispersion with a mass percent concentration of 0.005% and Cu(OH) 2 Nanowire solution, mixed according to the volume ratio of 3:1, mixed for 5 minutes under magnetic stirring to generate GO-Cu(OH) 2 nanowire floc suspension; the GO-Cu(OH) 2 The nanowire flocculent suspension was vacuum-filtered through a polycarbonate porous membrane, and a layer of 0.7 micron thick GO-Cu(OH) was formed on the polycarbonate porous membrane. 2 porous film, the GO-Cu(OH) 2 The pore size of the porous film is 6 nanometers;

[0063] 4) Treat GO-Cu(OH) with 1 mM acid solution 2 A porous film is obtained t...

Embodiment 2

[0065] 1) Ultrasonic dispersion of graphene oxide to obtain a graphene oxide dispersion with a mass percent concentration of 0.1%, for use;

[0066] 2) The same volume of 4 mM copper nitrate aqueous solution and 1.4 mM ethanolamine aqueous solution were mixed evenly under magnetic stirring, and then stood for 1 day to generate Cu(OH) 2 nanowire solution;

[0067] 3) The graphene oxide dispersion liquid with a mass percent concentration of 0.1% and Cu(OH) 2 Nanowire solution, mixed according to the volume ratio of 3:20, mixed for 5 minutes under magnetic stirring to generate GO-Cu(OH) 2 nanowire floc suspension; the GO-Cu(OH) 2 The nanowire floc suspension was vacuum-filtered through a polycarbonate porous membrane to form a layer of 2.5 micron thick GO-Cu(OH) on the polycarbonate porous membrane. 2 porous film, the GO-Cu(OH) 2 The pore size of the porous film is 8 nanometers;

[0068] 4) Treat GO-Cu(OH) with hydrazine hydrate solution at a molar concentration of 1 mM 2...

Embodiment 3

[0070] 1) Ultrasonic dispersion of graphene oxide to obtain a graphene oxide dispersion with a mass percentage concentration of 0.02%, for use;

[0071] 2) The same volume of 4 mM copper nitrate aqueous solution and 1.4 mM ethanolamine aqueous solution were mixed evenly under magnetic stirring, and then stood for 2 days to generate Cu(OH) 2 nanowire solution;

[0072] 3) The graphene oxide dispersion with a mass percent concentration of 0.02% and Cu(OH) 2 Nanowire solution, mixed according to the volume ratio of 3:10, mixed for 30 minutes under magnetic stirring to generate GO-Cu(OH) 2 nanowire floc suspension; the GO-Cu(OH) 2 The nanowire flocculent suspension was vacuum-filtered through a polycarbonate porous membrane, and a layer of GO-Cu(OH) with a thickness of 2 microns was formed on the polycarbonate porous membrane. 2 porous film, the GO-Cu(OH) 2 The porous film has a pore size of 8 nanometers;

[0073]4) Treat GO-Cu(OH) with 1 M acid solution 2 A porous film is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com