A deodorant composition applied to absorbent articles

A composition and absorbent technology, applied in the field of deodorant composition and its preparation, can solve the problems of limited application, narrow odor control range, etc., and achieve the effects of improving safety, easy handling, avoiding dust and online application loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

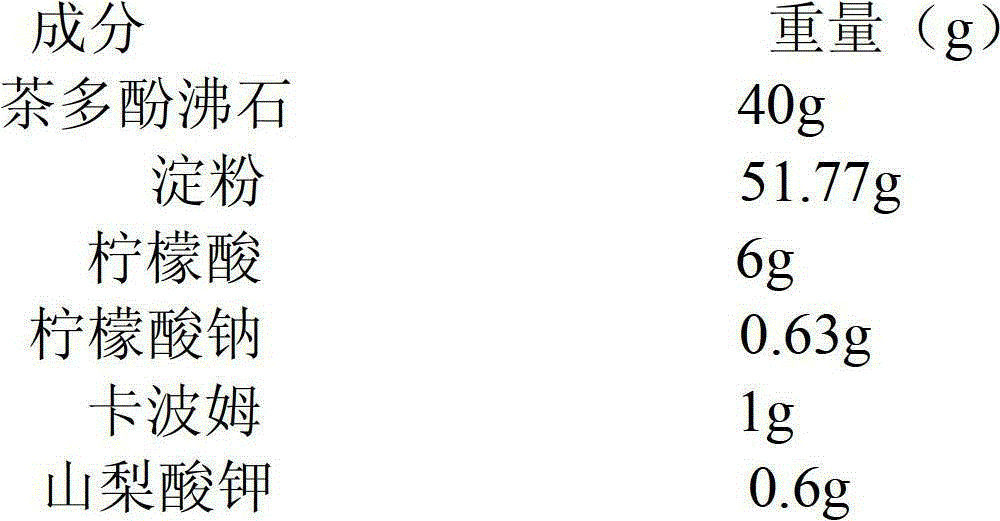

[0033] Embodiment one is calculated by every part of 10g

[0034]

[0035] 1) Use commercially available FAU zeolite powder, with a silicon-aluminum ratio of 72, and add it to the adsorption column. The adsorption column has a height of 45cm, an inner diameter of 3cm, and a zeolite adsorbent loading capacity of 120g.

[0036] 2) Weigh 10g of tea leaves, add 100ml of deionized water, extract at 70°C for 1 hour, filter to remove insoluble impurities, extract 3 times, combine the extracts, concentrate to 5% tea polyphenols content; adjust the flow rate to stabilize at 5.5ml / min , through the adsorption column. Then use 1 to 1.5 times column volume of deionized water to elute and remove impurities, take out the adsorbent, and remove excess water by suction filtration to obtain tea polyphenol zeolite.

[0037] The tea polyphenol extract with a tea polyphenol concentration of 5 is absorbed by an adsorption column filled with zeolite, and the column bed diameter-to-height ratio ...

Embodiment 2

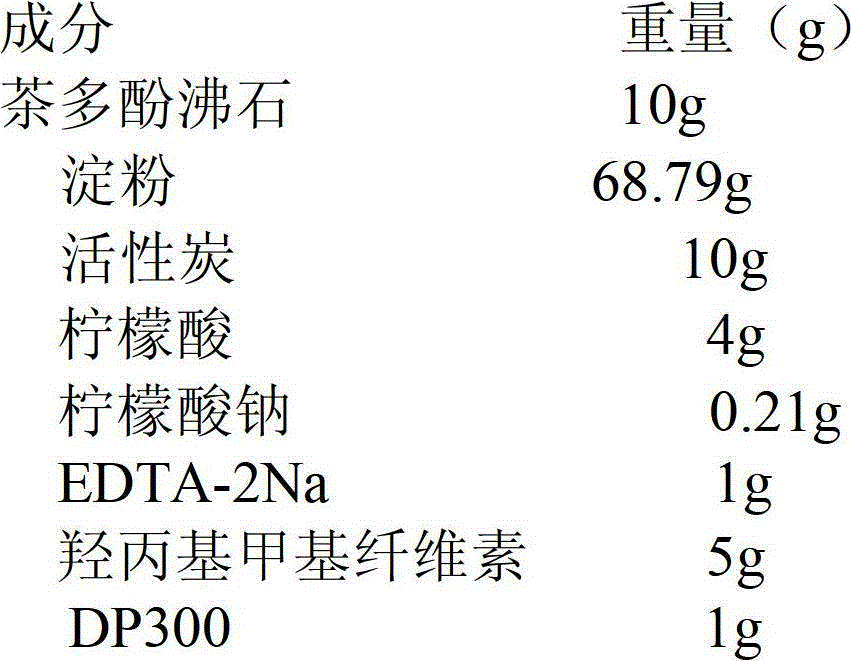

[0042] 10g per serving

[0043]

[0044] 1) Use commercially available FAU zeolite powder, with a silicon-aluminum ratio of 15, and add it to the adsorption column. The adsorption column has a height of 45cm, an inner diameter of 3cm, and a zeolite adsorbent loading capacity of 115g.

[0045]2) Weigh 100g of tea leaves, add 1500ml of deionized water, extract at 90°C for 2 hours, filter to remove insoluble impurities, extract twice, combine the extracts, concentrate to 2% tea polyphenols content; adjust the flow rate to stabilize at 10ml / min, through the adsorption column. Then use 1 to 1.5 times column volume of deionized water to elute and remove impurities, take out the adsorbent, and remove excess water by suction filtration to obtain tea polyphenol zeolite.

[0046] The tea polyphenol extract with a tea polyphenol concentration of 2 is absorbed by an adsorption column filled with zeolite, and the column bed diameter-to-height ratio H (zeolite filling height) / d (column...

Embodiment 3

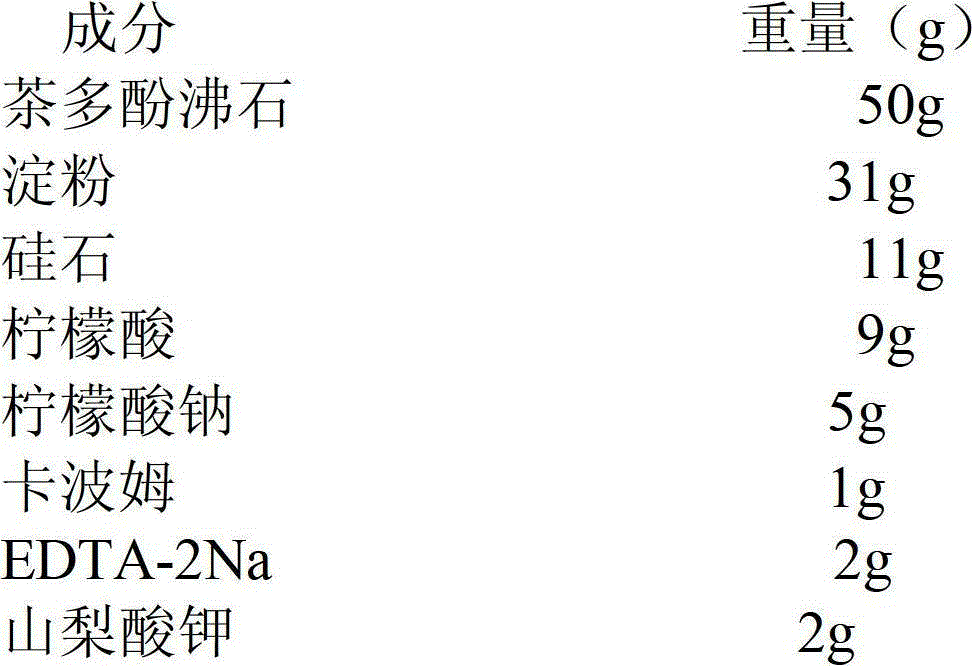

[0050] Embodiment three is in every part of 10g:

[0051]

[0052] 1) Use commercially available FAU zeolite powder, with a silicon-aluminum ratio of 72, and add it to the adsorption column. The adsorption column has a height of 45cm, an inner diameter of 3cm, and a zeolite adsorbent loading capacity of 120g.

[0053] 2) Weigh 100g of tea leaves, add 2000ml of deionized water, extract at 80°C for 1.5h, filter to remove insoluble impurities, extract twice, combine the extracts, concentrate to 8% tea polyphenols content; adjust the flow rate to stabilize at 8ml / min , through the adsorption column. Then use 1 to 1.5 times column volume of deionized water to elute and remove impurities, take out the adsorbent, and remove excess water by suction filtration to obtain tea polyphenol zeolite.

[0054] The tea polyphenol extract with a tea polyphenol concentration of 8% is absorbed by an adsorption column filled with zeolite, and the column bed diameter-to-height ratio H (zeolite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com