Method of measuring component contents in fluorite by applying X fluorescence powder tablet pressing method

A fluorescent powder and component content technology, which is applied in the direction of measuring devices, preparation of test samples, material analysis using wave/particle radiation, etc., can solve problems such as long preparation cycle and difficult analysis operation, and reduce inspection cost , Meet the error requirements of production process and analysis method, easy to grasp the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Embodiment: The steps of the method for determining the content of components in fluorite by using the X fluorescent powder pressing method are as follows.

[0026] 1. Use X-ray fluorescence spectrometer to create an analysis method: select the analysis parameters of the eight elements of calcium, fluorine, silicon, phosphorus, sulfur, iron, potassium and sodium, crystals, detectors, peak 2θ angles and measurement time, etc. as shown in Table 3.

[0027]

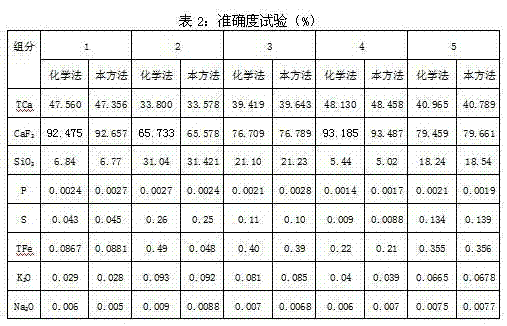

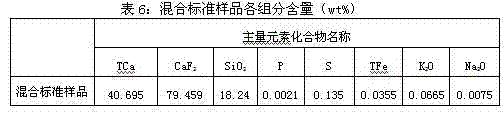

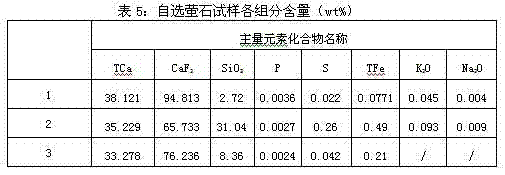

[0028] 2. Preparation of standard sample compression: select a suitable standard fluorite sample, the typical component content is shown in Table 4; at the same time, select a representative self-selected fluorite sample with a certain content gradient and use chemical method and ICP-OES method As a supplement after analysis and determination, the contents of some components are shown in Table 5 to obtain fluorite standard samples. Accurately weigh the fluorite standard sample and binder according to the ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com