Magnetic negative stiffness mechanism

A technology of negative stiffness and magnetic yoke, which is applied in the field of magnetic negative stiffness mechanism, can solve the problems of difficult miniaturization, increase of cost, and restrictions on the wide application of air bearing vibration reduction, etc., and achieve good high-frequency vibration interference and isolation of ultra-low-frequency vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

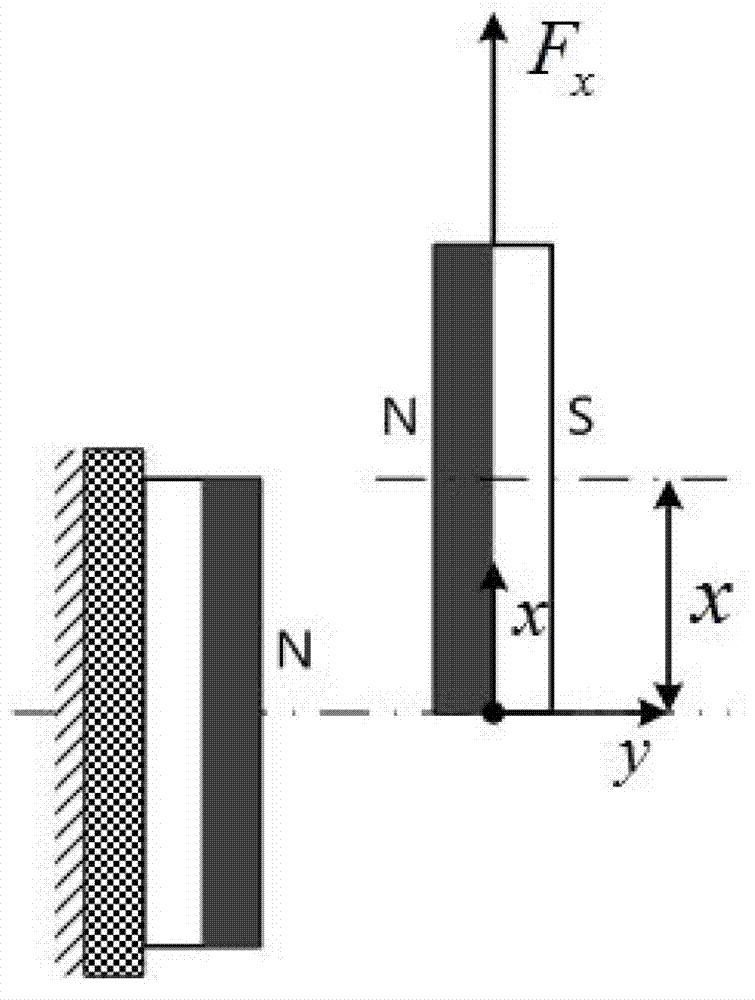

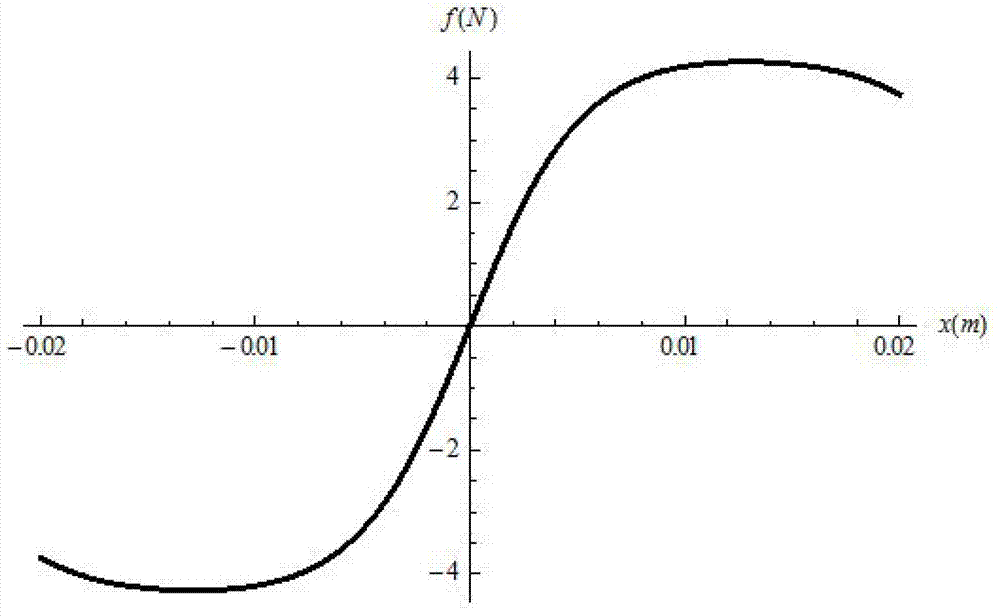

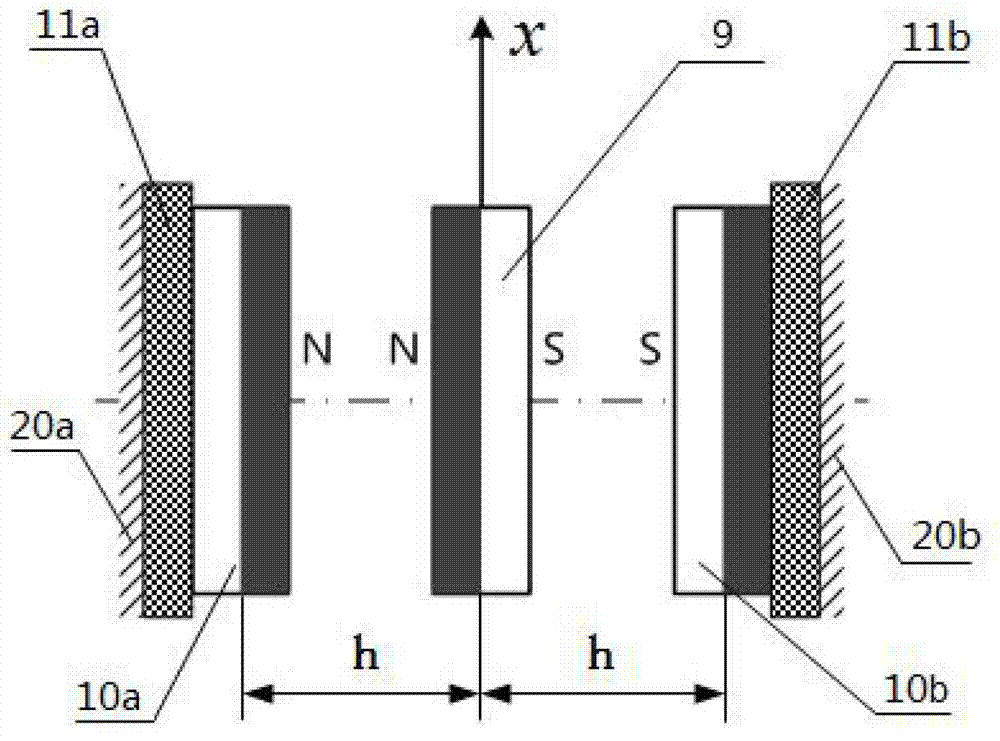

[0024] The magnetic pole part of the magnetic negative stiffness mechanism provided by the present invention adopts multiple groups of magnets arranged in parallel, and the magnetization directions of two adjacent magnets are opposite. Such a magnetic circuit arrangement constrains the magnetic force lines through the yoke, reduces magnetic flux leakage, and can improve the magnetic negative stiffness. body stiffness.

[0025] In the magnetic negative stiffness mechanism provided by the present invention, the negative stiffness can be adjusted by the negative stiffness adjusting part, which is used to match the stiffness of the positive stiffness spring connected in parallel with it, so as to adjust the stiffness of the shock absorber. Negative stiffness adjustment is achieved by adjusting the external magnet spacing.

[0026] The structure and working principle of specific embodiments of the present invention will be further described in detail below in conjunction with the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com