Industrial polyester filament for high-strength ultra-low-elongation safety belt and production method of industrial polyester filament

A manufacturing method and safety belt technology, applied in the direction of filament/thread forming, melting of filament raw materials, melt spinning method, etc., can solve the problems of high breaking strength, strong binding ability, low elongation, etc., and achieve improved flexibility Good flexibility, good flexibility, low modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

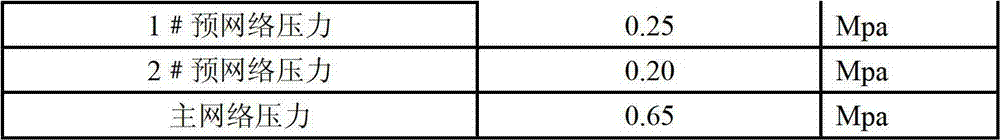

[0030] 1. The process parameters are as follows:

[0031]

[0032]

[0033] Second, the specific production process includes the following steps:

[0034] A. Preparation of high-viscosity polyester chips: using continuous solid-state polymerization method, first pre-crystallize low-viscosity polyester chips at a temperature of 170°C for 0.35 hours, and then enter a crystallization pre-crystallization temperature of 230°C The heater stays for 4.2 hours, then enters the main reactor, and performs solid phase repolymerization under the protection of hot nitrogen and a high temperature of 230°C. The material stays in the main reactor for a long time, generally about 22 hours, until the intrinsic viscosity is reached. Increased from conventional 0.63-0.67dL / g to 1.00dL / g, carboxyl-COOH is 12.0mol / t; diethylene glycol is 0.90%, and high-viscosity polyester chips are produced when the moisture content of the slices is reduced to 25ppm;

[0035] B. Impurity removal of high-visc...

Embodiment 2

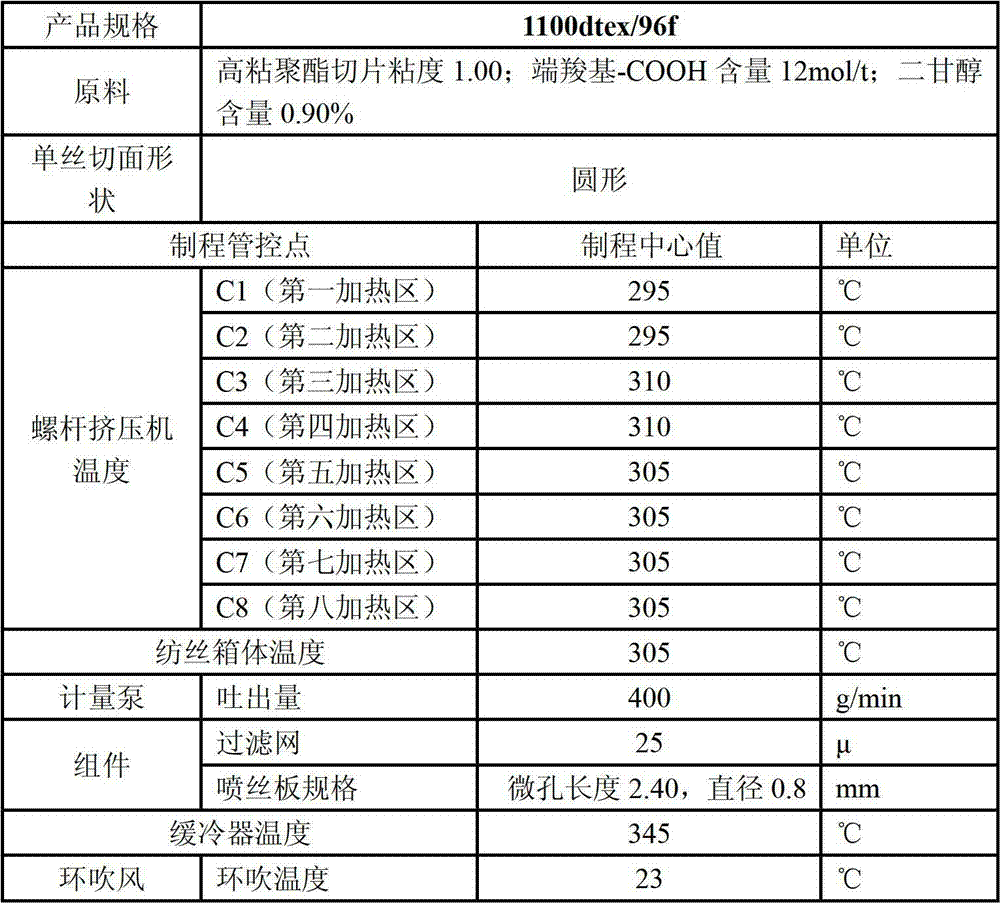

[0041] 1. The process parameters are as follows:

[0042]

[0043]

[0044] Second, the specific production process includes the following steps:

[0045] A. Preparation of high-viscosity polyester chips: adopt continuous solid-state polymerization method, first pre-crystallize low-viscosity polyester chips at a temperature of 170°C for 0.35 hours, and then enter a crystallization preheating temperature of 230°C The reactor stays for 4.2 hours, then enters the main reactor, and performs solid phase repolymerization under the protection of hot nitrogen and a high temperature of 230 ° C. The material stays in the main reactor for a long time, generally about 22 hours, so that the intrinsic viscosity is changed from conventional 0.63-0.67dL / g increased to 1.00dL / g, carboxyl-COOH is 12.0mol / t; diethylene glycol is 0.90%, and when the moisture content of the slice is reduced to 25ppm, high-viscosity polyester chips are produced;

[0046] B. Impurity removal of high-viscosity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com