Method for preparing ethanol by fermenting pentose and hexose mixed sugar by using pichia stipitis

A technology of Pichia stipitis and glycohexose, which is applied in the field of ethanol preparation and can solve the problems of incomplete fermentation and long fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

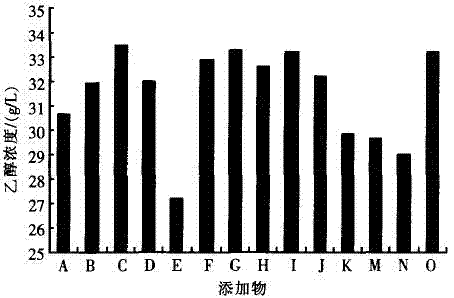

[0020] This implementation case illustrates the influence of different additives in the medium on fermentation. In this experiment, 80.0 g / L of mixed sugar (the ratio of glucose and xylose is 2:1), CaC1 2 0.3 g / L, MgSO 4 0.5 g / L, KH 2 PO 4 On the basis of 3.0 g / L basic medium, different substances were added to the medium to study their effects on fermentation. The fermentation temperature was 30°C, and the shaker speed was 150 r / min. The results were as follows: figure 1 shown.

[0021] from figure 1 It can be seen that the fermentation effect is very different with different additives, which is mainly reflected in the change of ethanol concentration. Among them, the ethanol concentration was significantly increased by adding substances C (wort juice 3.0 g / L+trace elements), G (soybean powder 3.0 g / L+trace elements+wort juice 3.0 g / L), P (trace elements), I (L- Glutamine 0.6 g / L+trace elements), its ethanol concentration was 33.4, 33.2, 33.2, 33.2 g / L in turn, which w...

Embodiment 2

[0024] This implementation case illustrates the influence of different temperatures on fermentation. The temperatures are: 30°C, 32°C, 34°C, 36°C and 38°C. The results are shown in Table 1.

[0025] It can be seen from Table 1 that the effect of fermentation temperature on ethanol fermentation with high sugar concentration is very significant. With the increase of fermentation temperature, the concentration of residual sugar experiences a process of first decreasing and then rising, while the change law of ethanol concentration and ethanol yield is similar to that of the opposite. When the temperature is between 30°C and 38°C, as the temperature increases, the concentration of residual sugar drops from 1.8 g / L at 30°C to 0.2 g / L at 32°C, and then rises to 19.4 g / L at 38°C. L, while the concentration of ethanol increased from 31.0 g / L to 33.5 g / L, and then decreased to 20.4 g / L, and the concentration of yeast after fermentation gradually decreased with the increase of fermentat...

Embodiment 3

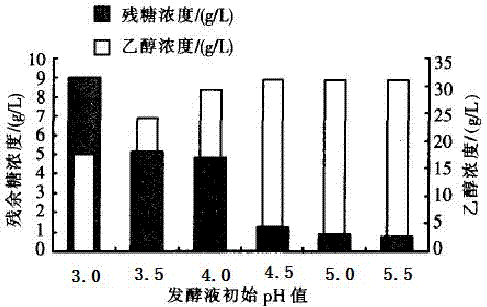

[0029] This implementation case illustrates the influence of different initial pH on fermentation. In this example, 80.0 g / L of mixed sugar (the ratio of glucose to xylose is 2:1) is used as the carbon source, and 0.05 moL / L of citric acid-citric acid tris Sodium adjusted the pH of the fermentation broth to investigate the effect of different initial pH on the production of ethanol by Pichia stipitis fermentation. The fermentation temperature was 30°C and the fermentation period was 24 h. The result is as figure 2 .

[0030] Depend on figure 2 It can be seen that when the initial pH of the fermentation broth rises from 3.0 to 5.5, the residual sugar concentration gradually decreases and the ethanol concentration gradually increases. When the pH was 3.0, the concentration of residual sugar was as high as 9.0 g / L, and the concentration of ethanol was only 17.5 g / L. Most of the yeast cells were deformed and lost their fermentation ability under the microscope. When the pH wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com