Method for fermenting ethanol by immobilized cells of Pichia stipitis

A technology of Pichia stipitis and immobilized cells, applied in the field of fermentation, can solve the problems of short service life and poor strength, and achieve the effects of increased service life and enhanced phosphate resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This implementation case illustrates the phosphate resistance of immobilized gel particles, and the test passed the Mn 2+ to Ca 2+ Replacement method, the formation of manganese alginate immobilized yeast cells significantly enhanced the phosphate resistance. The test process is as follows: Weigh 1 g of immobilized gel particles, dissolve them in 50 mL of phosphate neutral buffer with a concentration of 0.1 mol / L, shake intermittently at 35°C, and determine whether the immobilized gel particles crack. and dissolution time to test the phosphate resistance of the gel particles, the results are shown in Table 1.

[0023] It can be seen from Table 1 that different additives in calcium alginate gel particles have different phosphate resistance. The phosphate resistance of immobilized gel particles added with activated carbon did not improve significantly. Due to the relatively large surface area and porosity of activated carbon, adding it to calcium alginate gel particles ...

Embodiment 2

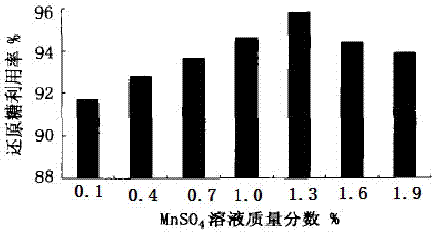

[0027] This implementation case illustrates the MnSO 4 Effect of solution concentration on ethanol fermentation of immobilized cells, preparation of 0.1%, 0.4%, 0.7%, 1.0%, 1.3%, 1.6% and 1.9% MnSO 4 solution, using Mn 2+ to Ca 2+ Replacement method, respectively prepared into manganese alginate immobilized yeast cells. The result is as figure 1 shown.

[0028] Depend on figure 1 Visible, MnSO 4 The concentration of the solution had a great influence on the ethanol fermentation of the immobilized yeast cells. When MnSO 4 When the solution mass fraction is 0.1%-1.3%, with the Mn 2+ With the increase of concentration, the utilization rate of reducing sugar increased gradually. When MnSO 4 When the solution mass fraction was 1.3%, the utilization rate of reducing sugar reached the maximum value of 95.7%. And when MnSO 4 When the solution mass fraction exceeds 1.3%, with the Mn 2+ As the concentration increased, the utilization rate of reducing sugar decreased instead...

Embodiment 3

[0030] This implementation case illustrates the effect of the pH of the fermentation broth on the ethanol fermentation of immobilized cells. 30 mL of manganese alginate immobilized proliferating yeast gel particles were put into 50 mL of mixed sugar with different pH (mixed sugar concentrated ethanol fermentation for 24 h) The degree of influence was 60 g / L, and the fermentation broth with 50% xylose and 50% glucose was fermented for 24 hours at 35°C and 150 r / min. The results are shown in Table 2.

[0031] It can be seen from Table 2 that the pH of the fermentation broth is in the range of 3.0 to 6.0, and the lower the pH of the fermentation broth, the more unfavorable the growth and reproduction of the manganese alginate-immobilized yeast cells. When the pH of the fermentation broth was 3.5, the residual sugar concentration was as high as 17.72 g / L, and the ethanol yield was 32.8% of the theoretical yield. When the pH of the fermentation broth was 4.0, the shape of the yeast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com