Method for preparing one-dimensional hollow superstructure photocatalytic material of Bi system composite oxide

A technology of composite oxides and photocatalytic materials, which is applied in the field of preparation of Bi-based composite oxide photocatalytic materials, can solve the problems of single structure, low sunlight-driven catalytic activity, and difficult recycling, and achieves improved efficiency and excellent solar energy. The effect of light-driven photocatalytic activity and preparation method is simple and feasible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

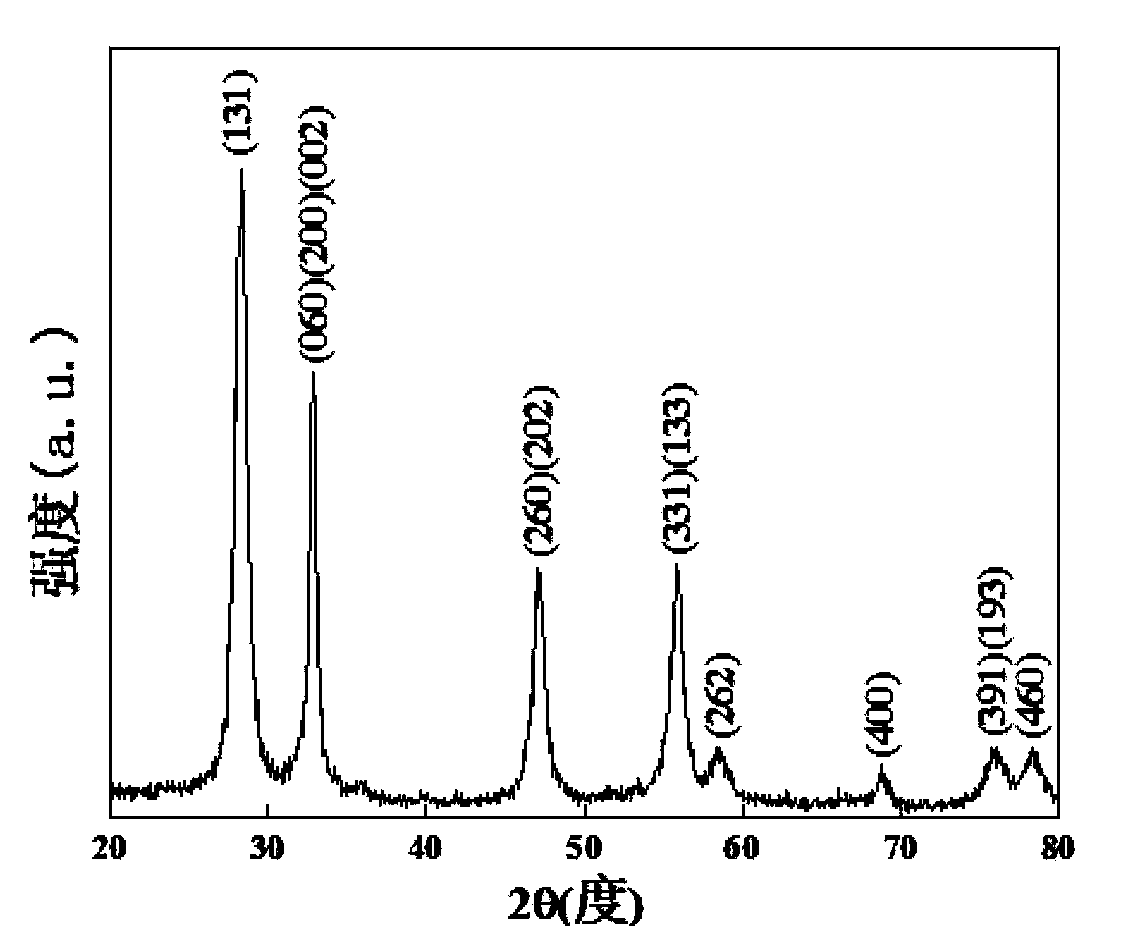

[0019] Specific embodiment one: In this embodiment, a method for preparing a Bi-based composite oxide one-dimensional hollow superstructure photocatalytic material is realized according to the following steps:

[0020] First, the one-dimensional Bi 2 o 3 The nanorods are dispersed in absolute ethanol, and then the aqueous solution of acetic acid is added dropwise until the pH value of the system is 3-6 to obtain a suspension;

[0021] 2. Dissolve the oxysalt in deionized water to obtain an aqueous solution of the oxysalt. Under the condition of magnetic stirring at 200-700 r / min, add the aqueous solution of the oxysalt to the suspension in step 1, and then transfer Put it in a stainless steel reaction kettle with a polytetrafluoroethylene liner, react at a temperature of 100-180°C for 6-14 hours, cool naturally to room temperature, wash with deionized water and absolute ethanol three times after centrifugation, and then put In an oven, dry at a temperature of 60°C for 6 hour...

specific Embodiment approach 2

[0025] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, acetic acid aqueous solution is added dropwise until the pH value of the system is 4-5.5. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0026] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that step 2 is reacted at a temperature of 120-160° C. for 8-11 hours. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com