A kind of preparation method of polyacrylate-polyester I-polyester II triblock copolymer

A polyacrylate and acrylate technology, which is applied in the field of preparation of polyacrylate-polyester I-polyester II triblock copolymer, can solve problems such as harsh reaction conditions, achieve simple operation, reduce production cost, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] In some embodiments, the preparation method of the present invention includes the following steps:

[0044] (1) The monomer mixed solution is mixed with a multifunctional chain transfer reagent, a catalyst and a free radical initiator to obtain a pre-reaction mixed solution; the monomer mixed solution is an acrylic ester monomer, an epoxy monomer, an acid anhydride A mixed solution of monomers and lactone monomers;

[0045] (2) reacting the pre-reaction mixed solution at 50-80° C. for 12-48 hours to obtain a reaction mixture;

[0046] (3) cooling the reaction mixture described in step (2) to room temperature (20-30° C.), quenching the reaction by introducing air, dissolving the reaction mixture with a polar organic solvent to obtain a mixed solution containing a block copolymer, Add the mixed solution containing the block copolymer dropwise into the precipitating agent to precipitate, filter and separate the precipitate, and dry to obtain the polyacrylate-polyester I-p...

Embodiment 1

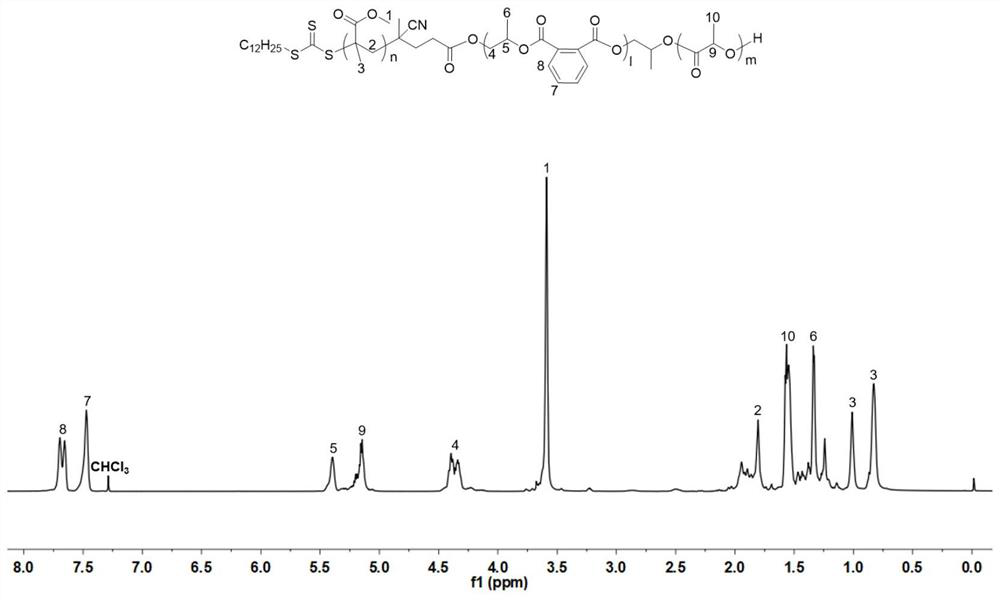

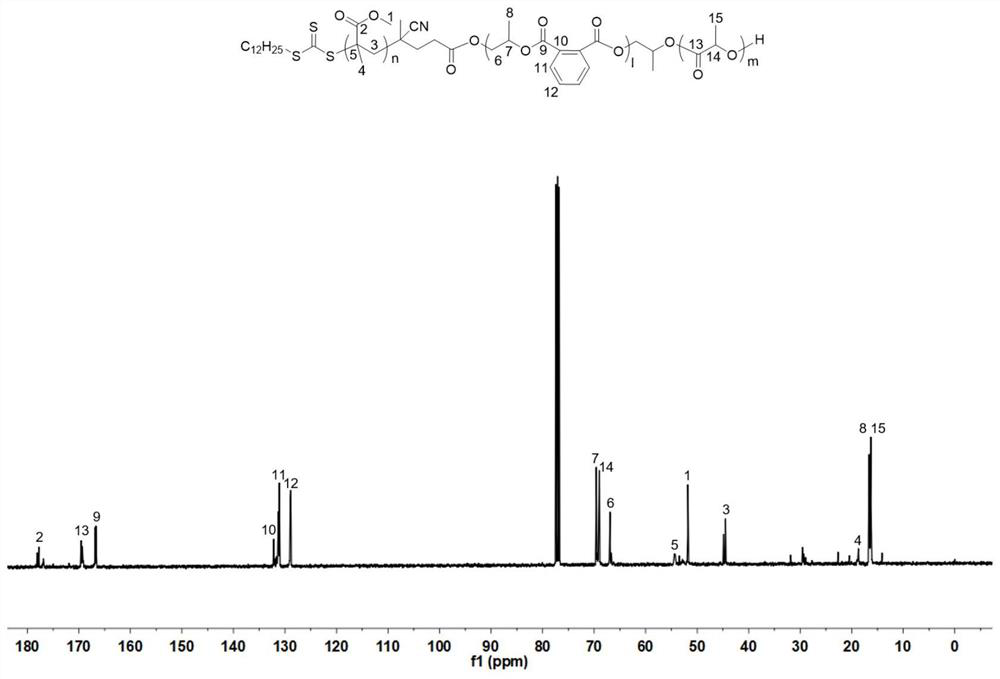

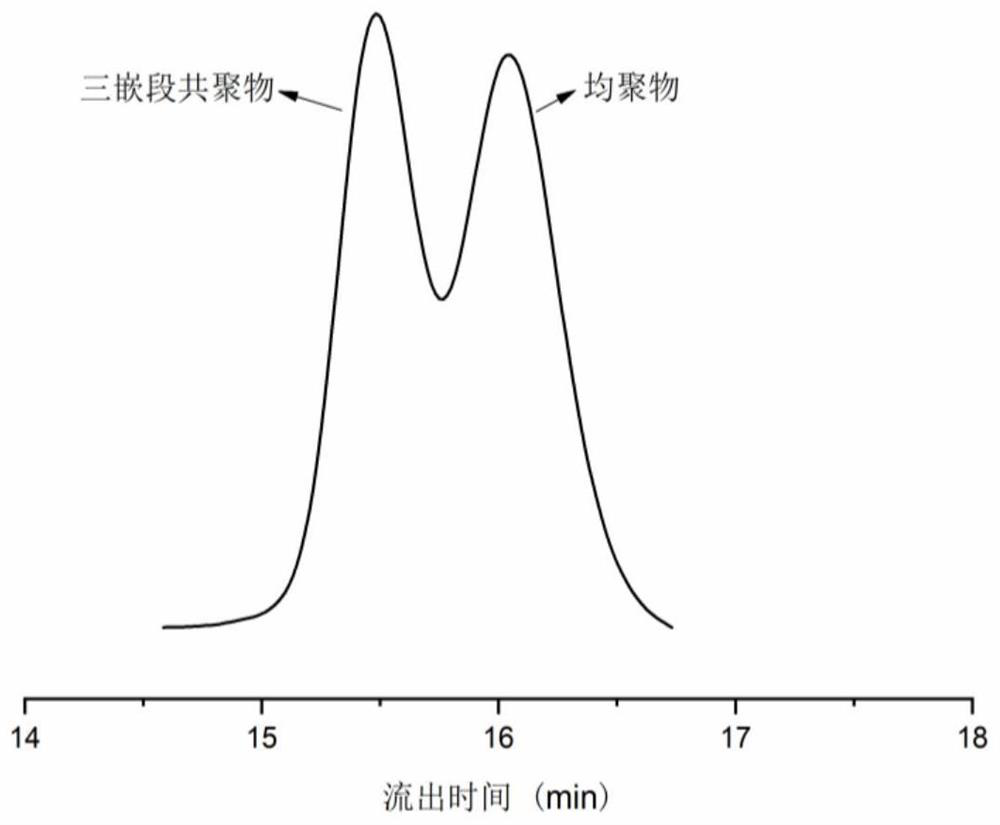

[0084] A preparation of polyacrylate-polyester I-polyester II triblock copolymer, under anhydrous and oxygen-free conditions, methyl methacrylate, 1,2-epoxybutylene, ε-caprolactone, After phthalic anhydride and multifunctional chain transfer reagent CTA-1 are mixed, triethyl boron and 1,5,7-triazide bicyclo (4.4.0) dec-5-ene and free radical initiator A one-step polymerization reaction under the combined action of azobisisobutyronitrile. Among them, CTA-1 is a carboxy-terminal trithioester compound with the following structure:

[0085]

[0086] The preparation of this polyacrylate-polyester I-polyester II triblock copolymer specifically comprises the following steps:

[0087] (1) Under anhydrous and anaerobic conditions, methyl methacrylate, 1,2-epoxybutylene, ε-caprolactone, phthalic anhydride and multifunctional chain transfer reagent CTA-1 are mixed according to 250: Take 2.6ml, 4.1mL, 0.5mL, 0.74g, and 80mg at a molar ratio of 500:50:50:2, respectively, and add them ...

Embodiment 2

[0092] A kind of preparation of polyacrylate-polyester I-polyester II triblock copolymer, under anhydrous and oxygen-free condition, benzyl methacrylate, propylene oxide, lactide, norbornene diacid anhydride and After the multifunctional chain transfer reagent CTA-2 is mixed, the composite catalyst triethylboron and 7-methyl-1,5,7-triazabicyclo (4.4.0) dec-5-ene and the free radical initiator couple A one-step polymerization reaction under the combined action of nitrogen diisoheptanonitrile. Among them, CTA-2 is a carboxyl-terminal trithioester compound with the following structure:

[0093]

[0094] The preparation of this polyacrylate-polyester I-polyester II triblock copolymer specifically comprises the following steps:

[0095] (1) Under anhydrous and oxygen-free conditions, benzyl methacrylate, propylene oxide, lactide, norbornene dioic anhydride and multifunctional chain transfer reagent CTA-2 according to 50:500:150:150: Take 0.85mL, 3.5mL, 2.16g, 2.46g, and 0.36g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com