Tyre bead for a large goods vehicle

A technology for tires and trucks, which is applied to tire beads and radial tires, and can solve problems such as tire degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

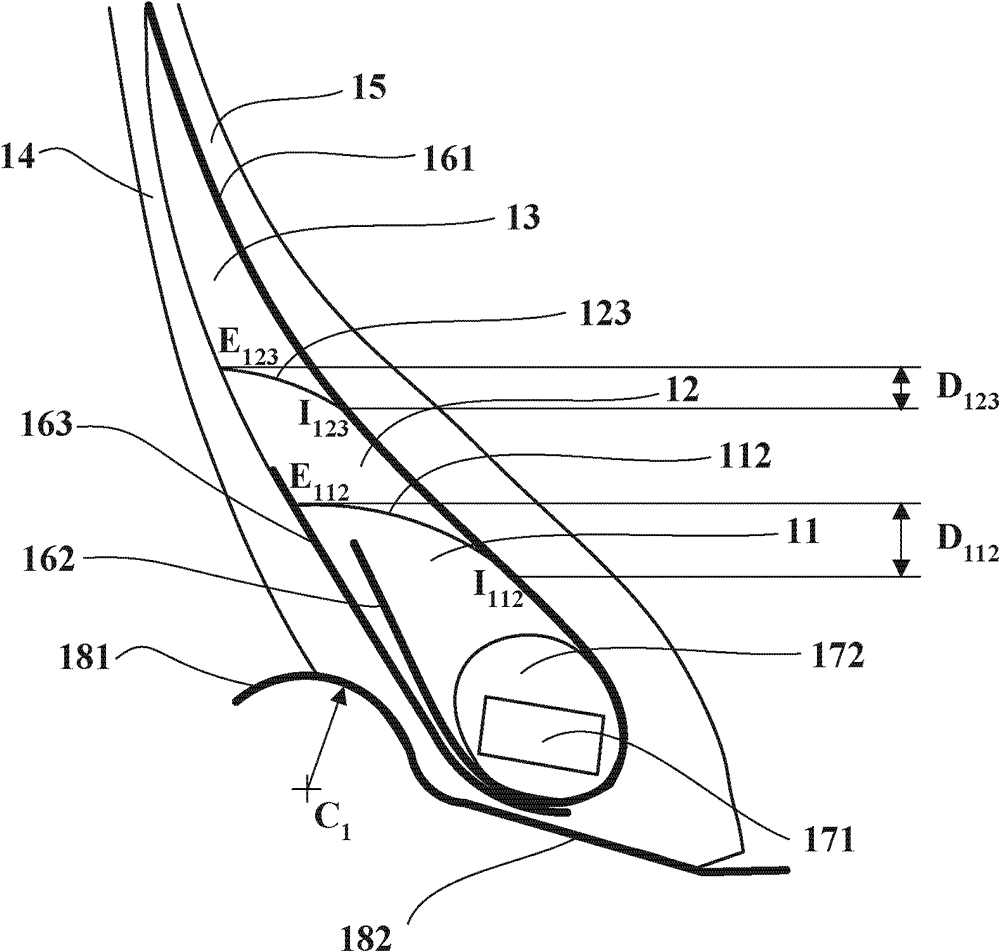

[0064] figure 1 A bead of a tire for heavy goods vehicles according to a preferred first embodiment of the invention is depicted.

[0065] This preferred first embodiment comprises in each bead:

[0066] - a main carcass reinforcement portion 161 comprising a single layer of metallic reinforcing elements, which is wrapped around a bead wire core forming a turnback 162,

[0067] - The bead wire core comprises a circumferential reinforcing element made of metal 171 surrounded by a polymer material 172 .

[0068] - additional reinforcement 163,

[0069] - a filler forming element such that the bead wire core extends radially outwards, having a triangular cross-section in any meridian plane and being stacked in radial direction by three polymer materials 11 , 12 , 13 Formed, the three polymer materials 11, 12, 13 are in contact with each other respectively along contact surfaces which intersect any meridian plane along the meridians 112, 123,

[0070] - the polymer material 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com