Drill with coolant holes

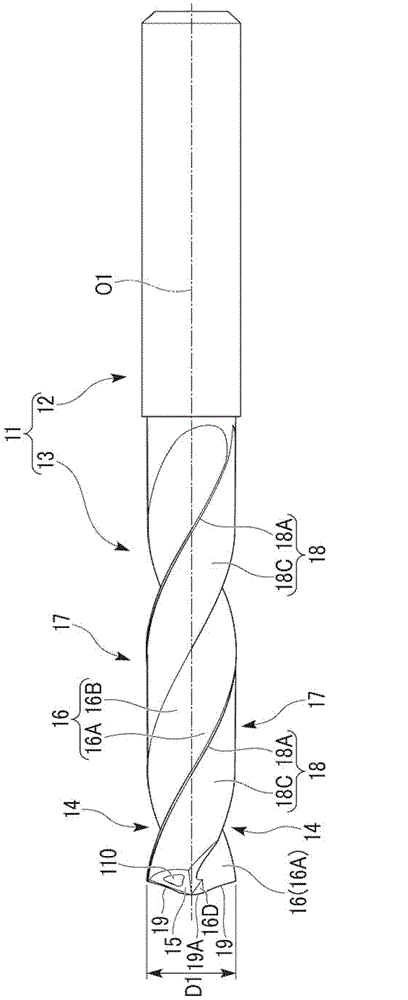

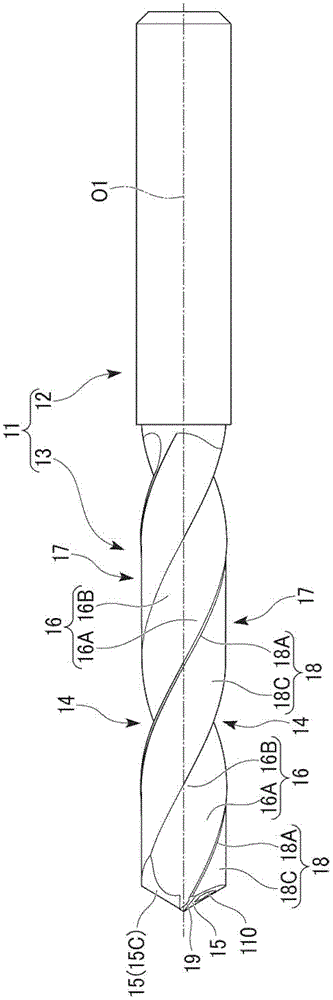

A technology for cooling holes and drill bits, which is applied in drilling/drilling equipment, drill repairing, twist drills, etc. It can solve problems such as accelerated wear, insufficient cooling fluid distribution, and decreased hole processing accuracy to achieve effective lubrication and cooling. , promote the increase, and promote the effect of supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0156] Hereinafter, with respect to the ratios of the intervals A1, B1, C1, E1, the width F1, and the angle α1 to the angle β1 in the above-mentioned embodiment, examples are given to verify that the above-mentioned ranges are appropriate.

[0157] Here, the ratios of the intervals A1, B1, C1, E1, the width F1, and the angle α1 to the angle β1 are set as examples (standard: BM) within the range of the above-described embodiment. On the other hand, those exceeding the upper limit value and the lower limit value of the range in the above-described embodiment are set as comparative examples. Furthermore, CAE analysis of Examples and Comparative Examples was performed. From the obtained result, the rigidity with respect to the torque when an Example was made into 100% was analyzed by relative evaluation. In addition, a fluid analysis of the flow of coolant flowing in the cooling holes is performed.

[0158] Here, the analysis of stiffness with respect to torque is performed unde...

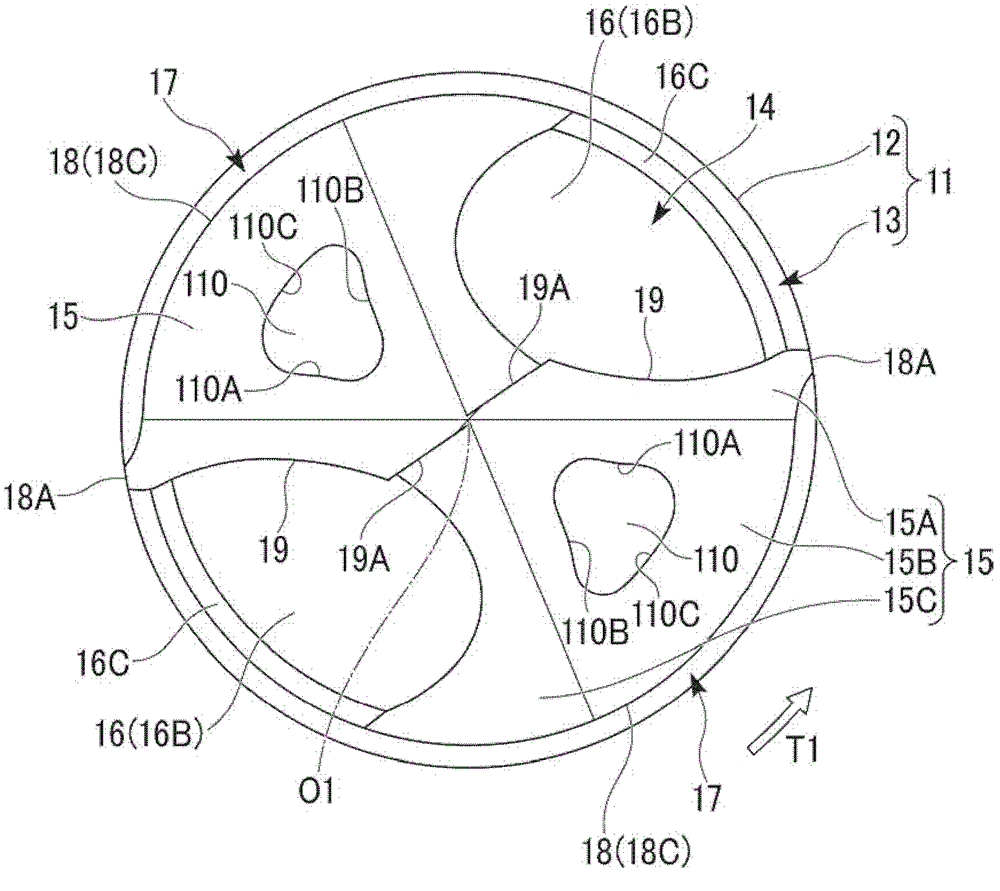

Embodiment 11

[0165] The example (BM) in which the interval C1 of the outer peripheral hole wall surface 110C of the cooling hole 110 and the outer peripheral wall surface (outer peripheral flank surface 18C) was set to 13% of the outer diameter D1 of the cutting edge 19 as described above was set to 100%. In this case, in the first comparative example, the interval C1 was set to 23% exceeding 20% of the outer diameter D1 of the cutting edge 19 . In the second comparative example, the interval C1 was set to 3% lower than 5% of the outer diameter D1 of the cutting edge 19 . exist Figure 13 The results of relative stiffness with respect to torque based on CAE analysis of Examples and Comparative Examples are shown in FIG. Furthermore, in Figure 14 The results of the relative comparison of the outlet flow rates of the cooling holes of the Example and the Comparative Example are shown in FIG.

[0166] According to this result, in the first comparative example in which the distance C1 bet...

Embodiment 12

[0168] The interval A1 is the interval between the front hole wall surface 110A of the cooling hole 110 and the front groove wall surface 16A of the chip discharge groove 14 . The interval B 1 is the interval between the rear hole wall surface 110B of the cooling hole 110 and the rear groove wall surface 16B of the chip discharge groove 14 . The example (BM) in which both the interval A1 and the interval B1 are 10% of the outer diameter D1 of the cutting edge 19 is assumed to be 100%. In this case, in the first comparative example, the interval A1 and the interval B1 were set to 17% exceeding 15% of the outer diameter D1 of the cutting edge 19 .

[0169] In the second comparative example, the interval A1 and the interval B1 were set to 2%, which is lower than 3%. exist Figure 15 Results of relative stiffness to torque based on CAE analysis for these Examples and Comparative Examples are shown in . Furthermore, in Figure 16 The results of the relative comparison of the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com