Solid dispersions containing an apoptosis-promoting agent

A technology of solid dispersion and solid matrix, which can be used in medical preparations containing active ingredients, organic active ingredients, oil/fat/wax non-active ingredients, etc., and can solve problems such as impracticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0217] Embodiment 1: Preparation of the solid dispersion of ABT-263 diHCl

[0218] ABT-263 diHCl crystalline salt was mixed with surfactant and water-soluble polymer in the following weight ratio:

[0219] 10.8% ABT-263 salt (10% free base equivalent); 10% surfactant; 79.2% polymer

[0220] 21.5% ABT-263 salt (20% free base equivalent); 10% surfactant; 68.5% polymer

[0221] 32.3% ABT-263 salt (30% free base equivalent); 10% surfactant; 57.7% polymer

[0222] 43% ABT-263 salt (40% free base equivalent); 10% surfactant; 47% polymer

[0223] Surfactants in different series are TPGS, Span™ 20 or Tween™ 20. The polymers in different series are copovidone (Kollidon® VA 64), povidone K-30 or HPMC-AS.

[0224] The ingredient mixture was dissolved in methanol in each case. Methanol was removed in vacuo at 65°C using a Genevac® system, and the resulting solid dispersion was allowed to cool to ambient temperature.

[0225] The solid dispersion in each case was sieved through a 4...

Embodiment 2

[0228] Embodiment 2: Preparation of solid dispersion of ABT-263 free base

[0229] ABT-263 diHCl crystalline salt was dissolved in acetone, and NaOH was added to convert ABT-263 diHCl to free base. The NaCl by-product was precipitated and removed by filtration.

[0230] In the acetone solution of obtained ABT-263 free base, add surfactant and water-soluble polymer of following weight ratio:

[0231] 10% ABT-263 free base; 10% surfactant; 80% polymer

[0232] 20% ABT-263 free base; 10% surfactant; 70% polymer

[0233] 30% ABT-263 free base; 10% surfactant; 60% polymer

[0234] 40% ABT-263 free base; 10% surfactant; 50% polymer

[0235] Surfactants in different series are TPGS, Span™ 20 or Tween™ 20. Polymers in different series are copovidone (Kollidon® VA 64) or HPMC-AS.

[0236] Acetone was removed in vacuo at 65°C using a Genevac® system, and the resulting solid dispersion was allowed to cool to ambient temperature.

[0237] The solid dispersion in each case was sie...

Embodiment 3

[0240] Example 3: Dissolution Profile of Solid Dispersions

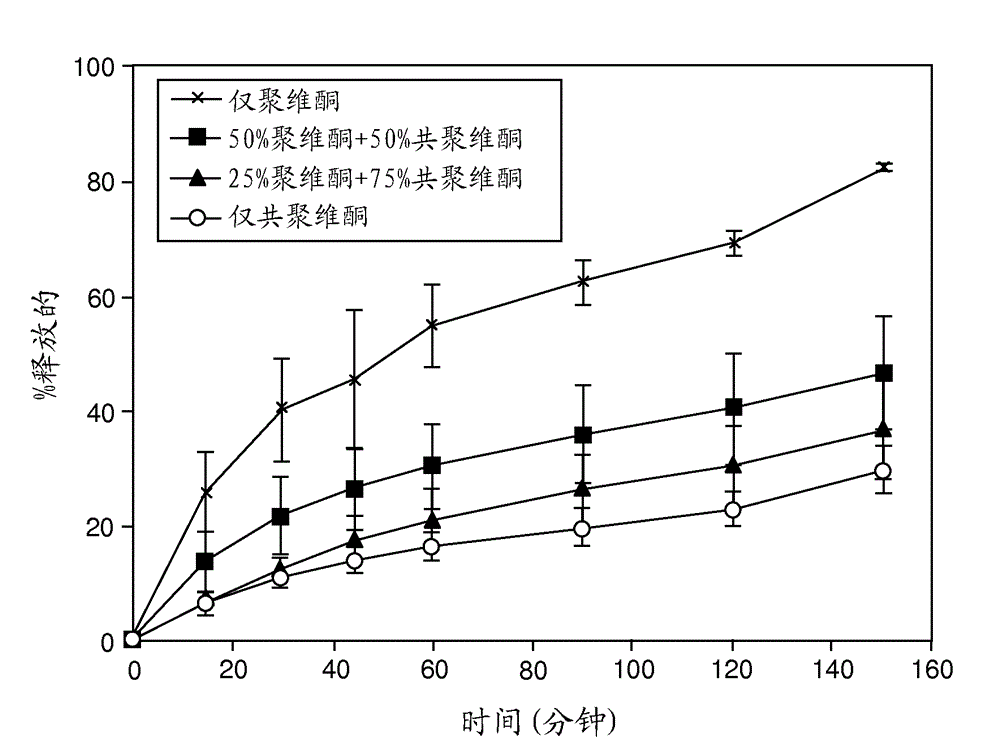

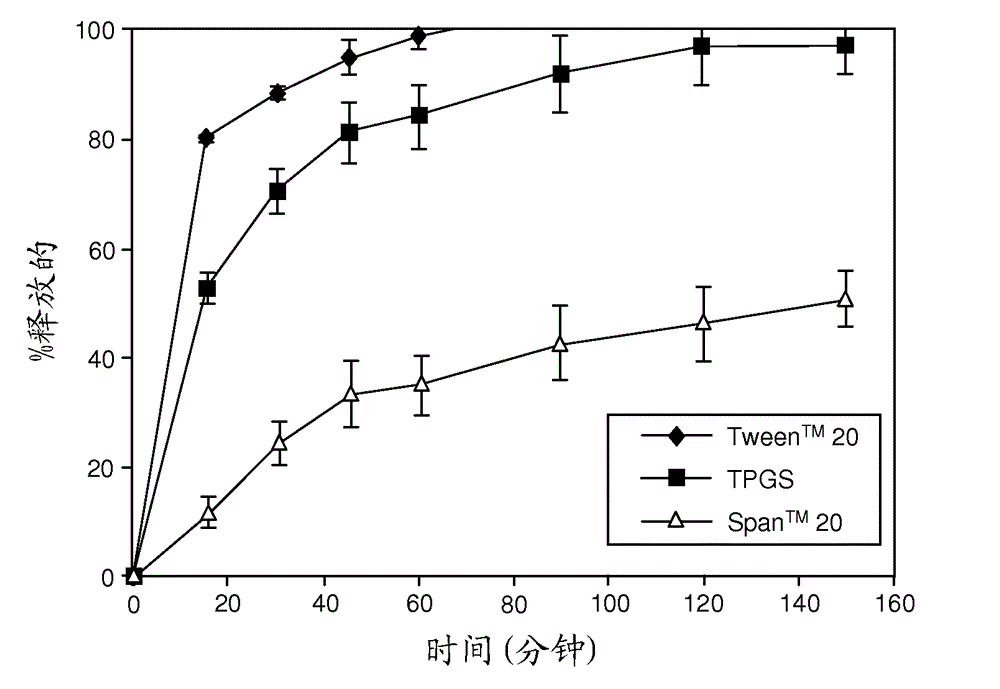

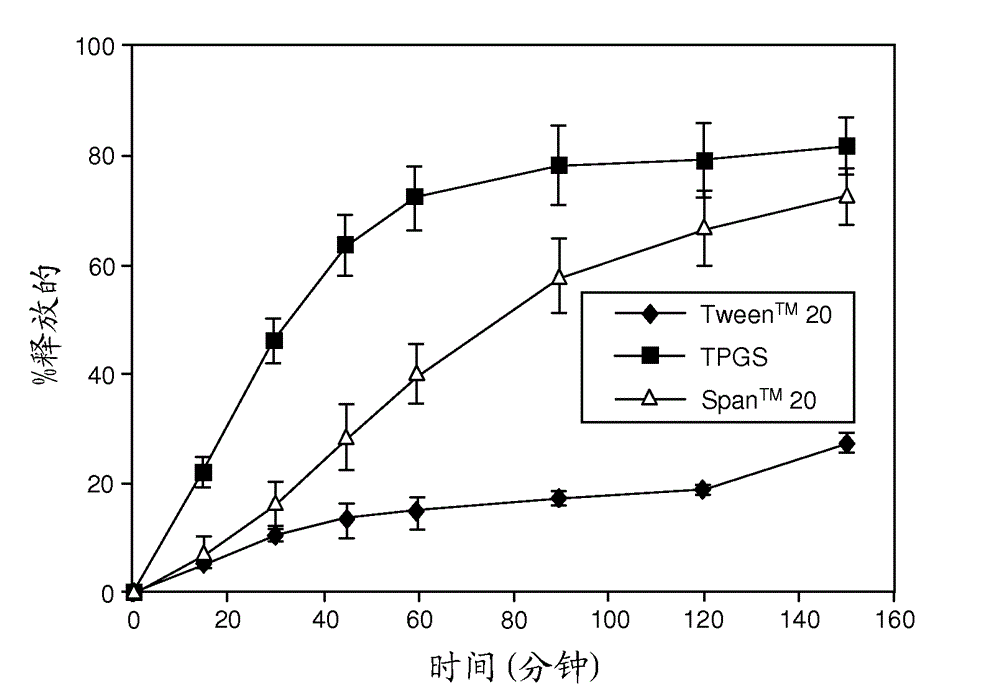

[0241]Representative dissolution (drug release) profiles in pH 6.5 buffered media containing 7.6 mM Tween® 80 are shown in figure 1 (ABT-263 diHCl) and figure 2 (ABT-263 free base).

[0242] like figure 1 As shown in , at 20% drug loading level, ABT-263 diHCl solid dispersion with 68.5% copovidone and 10% TPGS showed a moderate rate of drug release, which reached a plateau at about 80% release. The release from similar dispersions with Span™ 20 or especially Tween™ 20 as surfactant was much slower.

[0243] In contrast, if figure 2 ABT-263 free base solid dispersion with 70% copovidone and 10% Tween® 20 or TPGS showed fast drug release at the same 20% drug loading level as shown in . In the case of the free base dispersion, only Span™ 20 surfactant resulted in a much slower release.

[0244] The release rate was drug load dependent for both ABT-263 diHCl and free base dispersion formulations, with the 20%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com