Cyclone boiler

A cyclone, boiler technology, applied in the directions of combustion air/fuel supply, combustion method, solid fuel combustion, etc., can solve the problem that the inhibition effect of tar lumps on the furnace wall is not ideal, and it is difficult to maintain the thermal efficiency of the furnace wall and the cyclone wind power. limited and other problems, to achieve the effect of reducing furnace heat radiation, simple structure, and strengthening oxygen supplementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

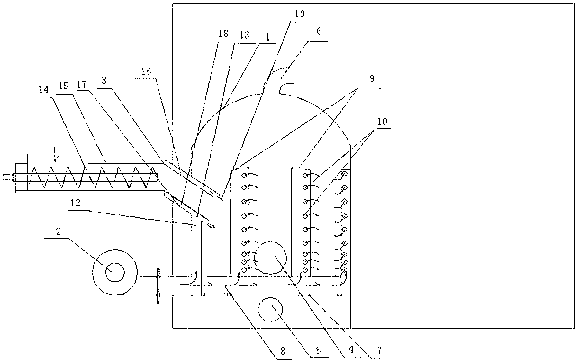

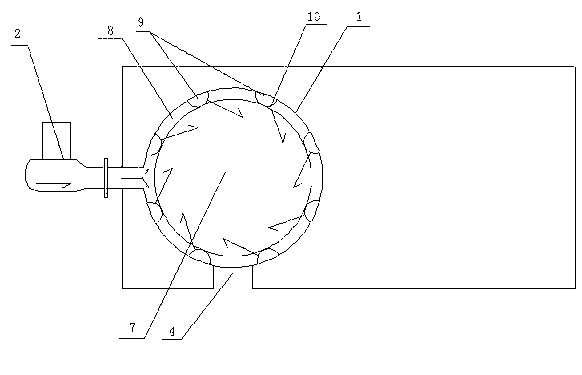

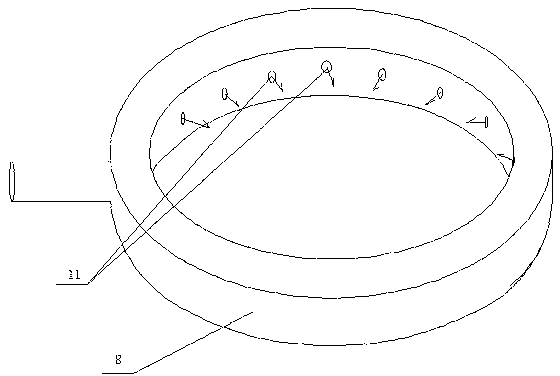

[0019] Such as figure 1 , figure 2 with Figure 5 As shown, the cyclone boiler includes a furnace wall 1, a blower 2 and a particle feeding dragon 3, the particle feeding dragon 3 is connected above the middle part of the furnace wall 1, the lower end of the furnace wall 1 is provided with a furnace door 4 and an ash outlet 5, and the top It is connected with a flue gas discharge pipe 6, and there is a fire grate 7 near the bottom. A furnace wall air duct 8 is arranged along the furnace wall 1. Two air ducts connected to the furnace wall air duct 8 are provided above the furnace wall air duct 8. The above air duct 9 with the top closed, the air duct 9 is placed vertically, and when viewed from the inside of the boiler toward the furnace wall 1, the air duct 9 has a ventilation hole 10 on the same side of the axis, so that the air blown out in the ventilation hole 10 A vortex is formed in the furnace; the fire grate 7 is arranged below the furnace wall air duct 8; see imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com