Combustion heat recovery device for combustible exhaust gas of carbonized oven

A heat recovery device and waste gas combustion technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of heat pollution and waste of combustible gas in production workshops, ensure effective recovery, increase heat absorption, and prevent combustible exhaust gas. The effect of burning heat to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

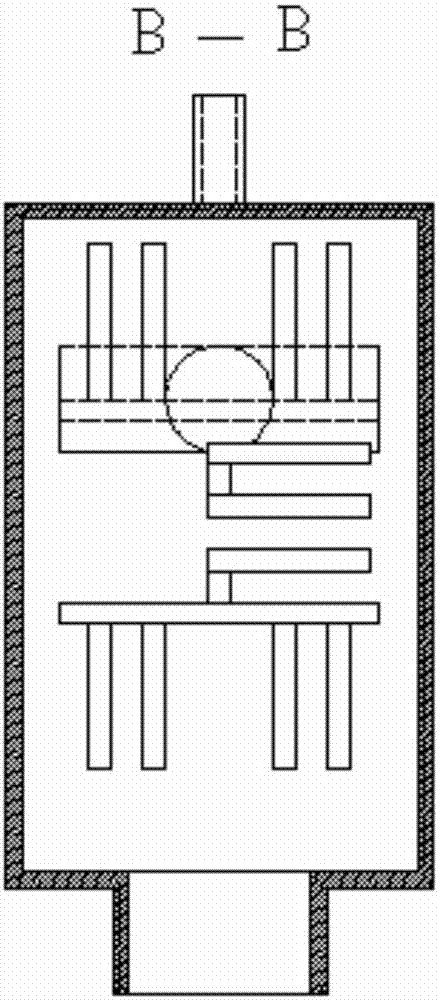

[0025] like Figure 1-3 As shown, the present invention provides a carbonization furnace combustible waste gas combustion heat recovery device, including a waste heat recovery chamber 5 and a waste heat recovery pipe passing through the waste heat recovery chamber. Effectively prevent the combustion heat of combustible waste gas from dissipating to the environment, and ensure the heat inside the device; at the same time, it is convenient for the operator to observe the situation inside the device at any time and take relevant measures; the waste heat recovery chamber is provided with a combustion port and a combustion product exhaust port 8, specifically, The combustion port is arranged at the bottom of the waste heat recovery chamber, and the top of the waste heat recovery chamber is provided with two combustion product exhaust ports, and the two combustion product exhaust ports are distributed on both sides of the waste heat recovery chamber; the waste heat recovery pipe incl...

Embodiment 2

[0032] Compared with Embodiment 1, the difference of this embodiment is that the serpentine pipe body includes a plurality of vertical serpentine pipe body segments 3 and horizontal serpentine pipe body segments 6 that are alternately connected. The serpentine pipe body includes a plurality of alternately connected vertical serpentine pipe body sections and horizontal serpentine pipe body sections, thereby increasing the coverage area and the heating surface, greatly increasing the heat exchange area of the heat transfer medium, so that the heat transfer medium can Absorb more heat and maximize heat recovery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com