Gas stove as well as burner cap and furnace end of burner for gas stove and burner

A technology for burners and gas stoves, which is applied to gas fuel burners, burners, combustion methods, etc., can solve problems such as high cost and complex structure, and achieve the effects of reducing emissions, improving thermal efficiency, and widening the range of firepower or power control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

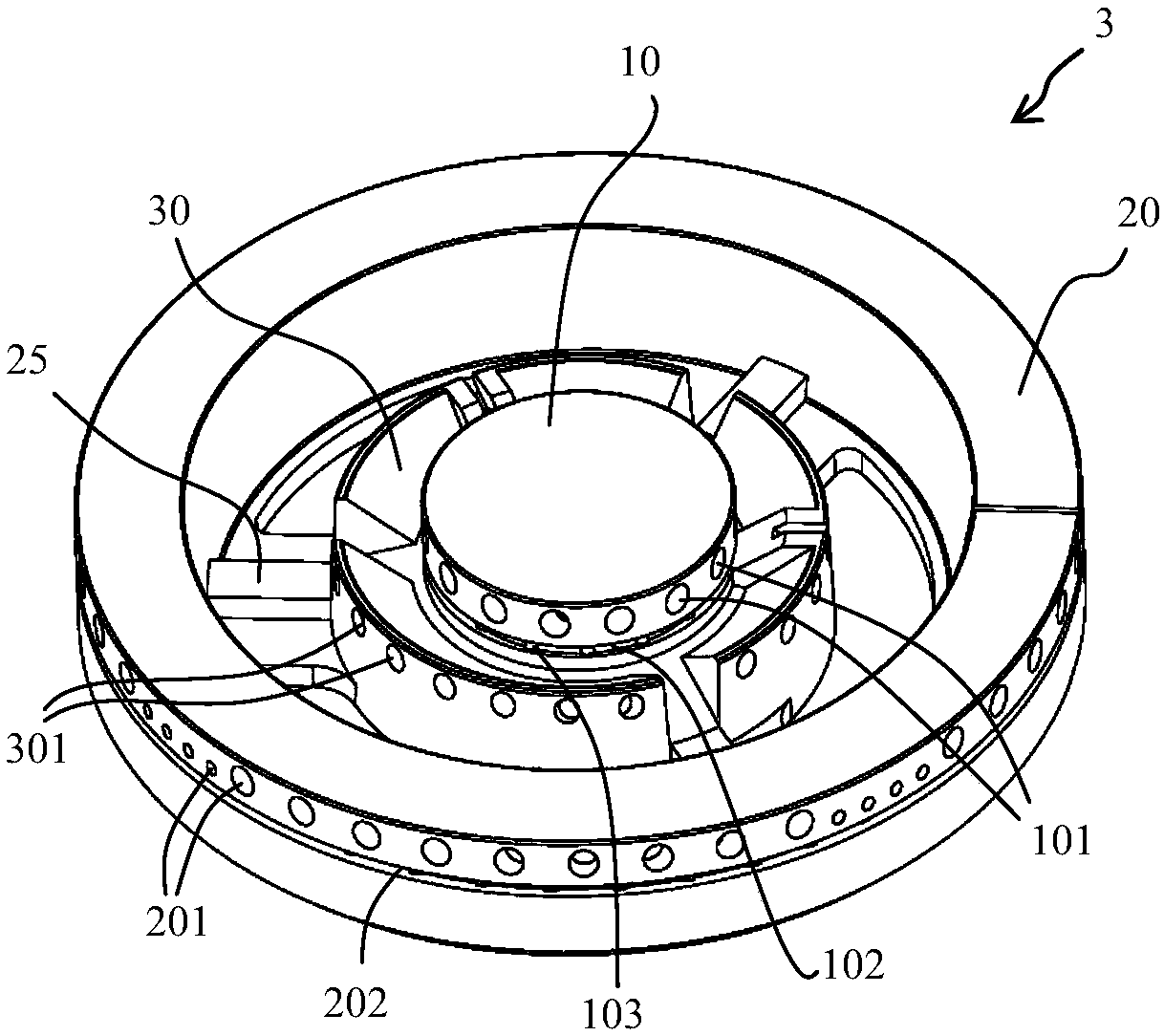

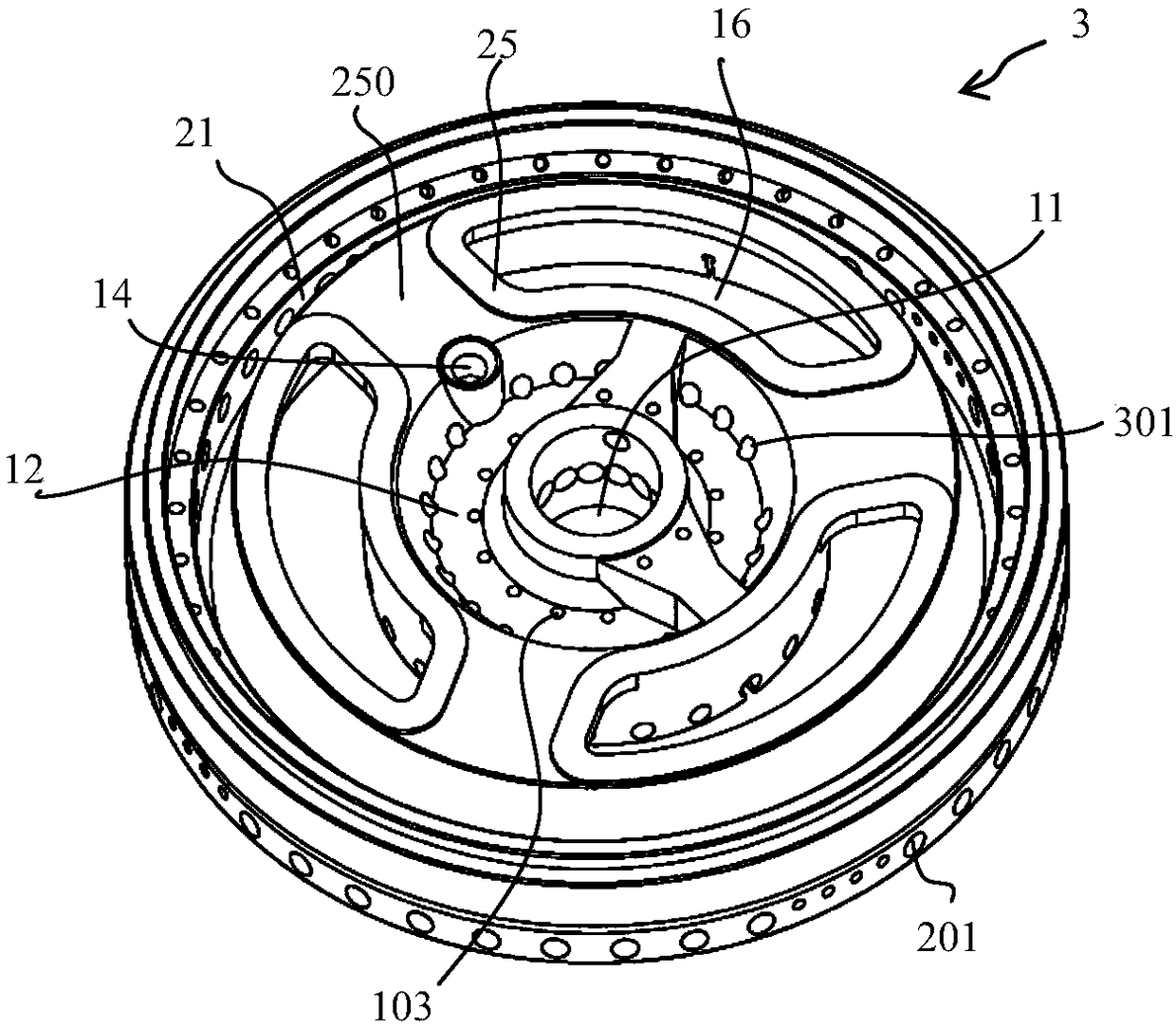

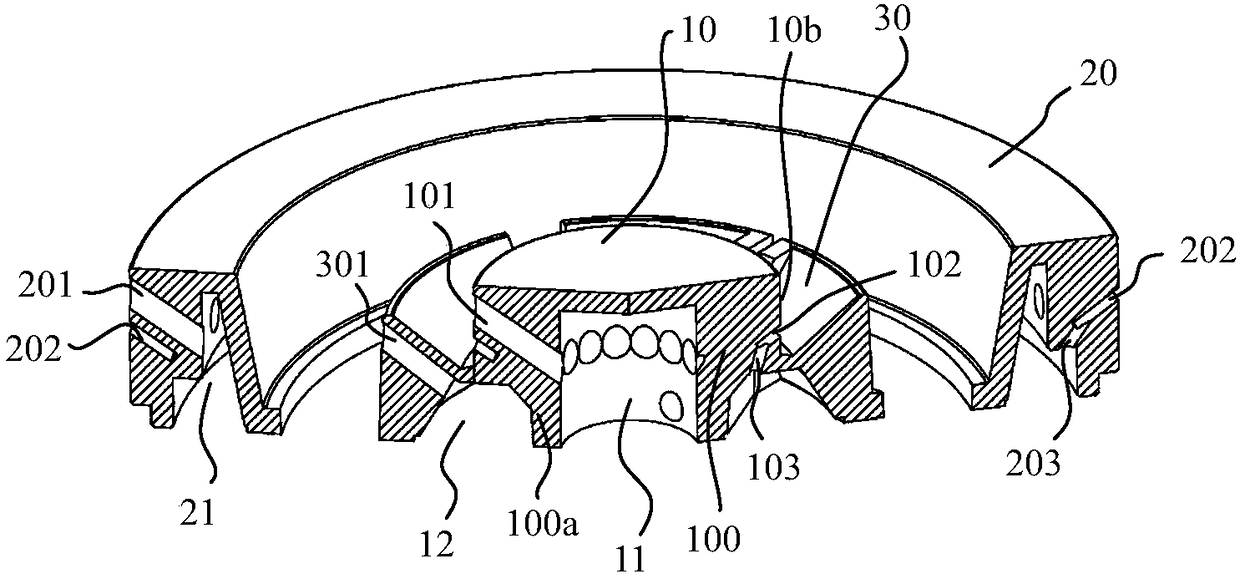

[0047] First, please refer to Figure 1 to Figure 3 , figure 1 It is a perspective view of a fire cover according to an embodiment of the present invention; figure 2 It is a bottom-up perspective view of a fire cover according to an embodiment of the present invention; image 3 It is a cross-sectional view of a fire cap according to an embodiment of the present invention. This embodiment shows a fire cover 3 for a burner for a gas stove, which is an integrally formed integral part. The fire cover 3 includes an inner ring cover part 10 , an outer ring cover part 20 and a middle ring cover part 30 .

[0048] The bottom of the inner ring cover 10 has a concave first recess 11, the first recess 11 is used to accommodate the gas supplied by the inner ring gas nozzle, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com