Method for arranging water-cooled wall of vertical pipe panel of internal thread pipe with non-uniform caliber

A technology of internal threaded pipes and layout methods, applied in boiler water pipes and other directions, to achieve the effects of reducing water pump power consumption, reducing temperature deviation, and reducing pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

[0015] The working fluid enters the water-cooled wall from the lower header of the furnace, absorbs heat in the water-cooled wall and then enters the outlet header of the water-cooled wall. This embodiment discloses a method for arranging the above-mentioned water-cooled wall, and its specific steps are:

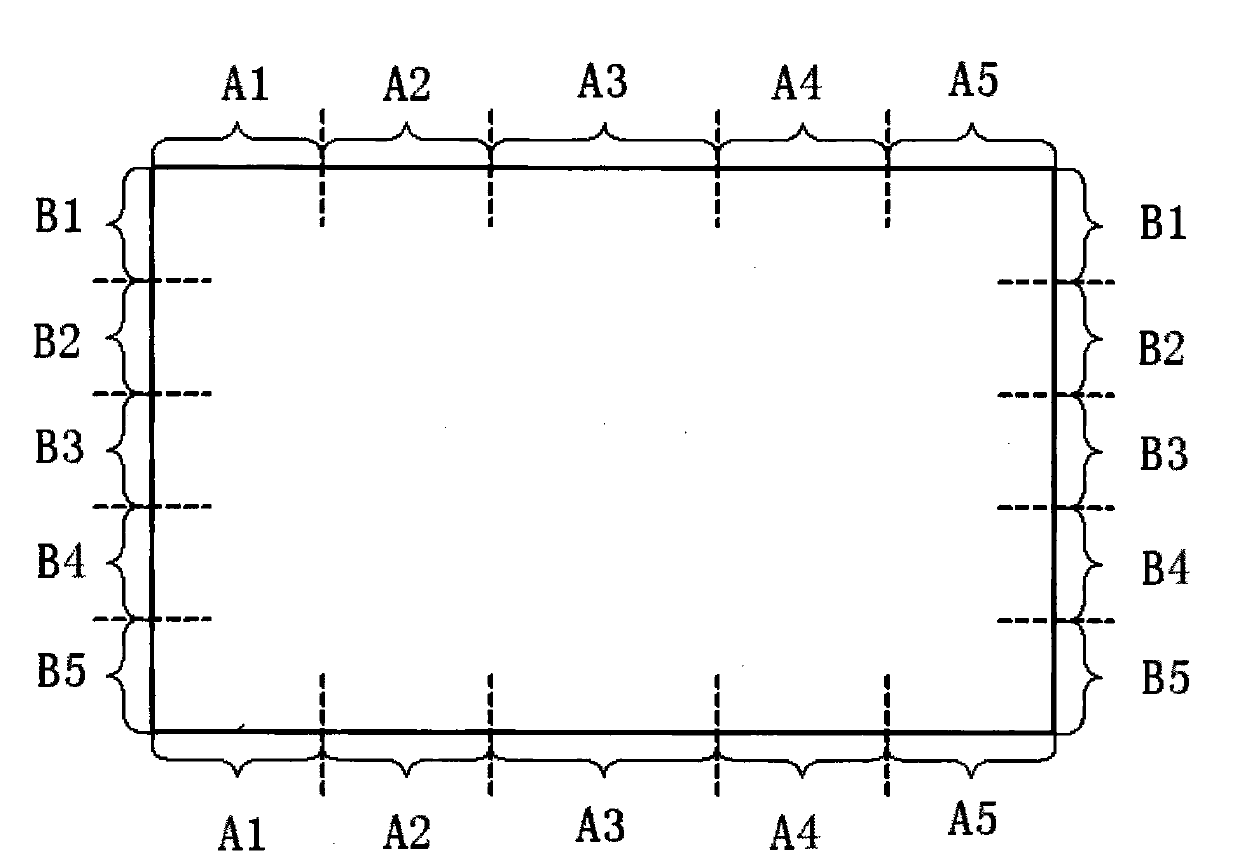

[0016] The vertical tube panel is used to raise the water wall at one time, and the vertical tube panel adopts internal threaded tubes with non-uniform tube diameters. like figure 1 As shown, the vertical tube panel is divided into five groups of water-cooled tube panel along the width direction of the furnace, which are respectively water-cooled tube-panel group A1, water-cooled tube-panel group A2, water-cooled tube-panel group A3, and water-cooled wall tube-panel group A4 and water wall tube panel group A5; or divided into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com