Preparation method of oil-water separation filter paper

A technology of oil-water separation and filter paper, which is applied in the direction of separation method, filter paper, filtration separation, etc., can solve the problems of numerous follow-up problems, complex process, harsh conditions, etc., and achieve the effect of short cycle, simple process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

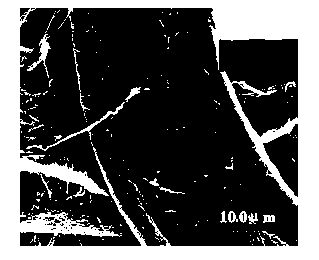

Image

Examples

Embodiment 1

[0022] The present embodiment provides a kind of preparation method of oil-water separation filter paper, carries out according to the following steps:

[0023] Step 1. Ammonia water with a volume fraction of 10% of absolute ethanol and 10% tetraethyl orthosilicate were successively added to absolute ethanol, magnetically stirred at room temperature for 1 h, left to stand, and aged for 12 h;

[0024] Step 2: Add octadecyltrichlorosilane with a volume fraction of 0.6% ethanol to the aged mixture, stir magnetically for 12 h, wash with alcohol, centrifuge, and vacuum dry at 60°C for 12 h to prepare hydrophobic silica particles;

[0025] Step 3, prepare the THF solution of polystyrene, the consumption of polystyrene is 20% (m / v) of THF;

[0026] Step 4, prepare hydrophobic silicon dioxide / polystyrene / THF mixed solution, evenly disperse hydrophobic silicon dioxide particles in the solution obtained in step 3, wherein the amount of hydrophobic silicon dioxide particles is 20% (m / ...

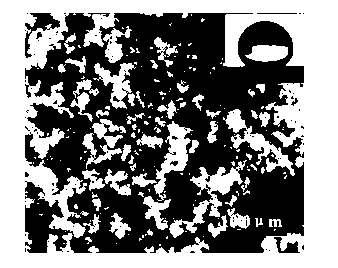

Embodiment 2

[0030] The present embodiment provides a kind of preparation method of oil-water separation filter paper, carries out according to the following steps:

[0031] Step 1. Add ammonia water with a volume fraction of 7% of absolute ethanol and 10% tetraethyl orthosilicate to absolute ethanol successively, ultrasonicate in a water bath at 37°C for 2 h, let stand, and age for 0.5 h;

[0032] Step 2: Add octadecyltrichlorosilane with a volume fraction of 0.8% ethanol to the aging mixture, stir magnetically for 2 h, wash with alcohol, centrifuge, and vacuum dry at 60°C for 6 h to prepare hydrophobic silica particles;

[0033] Step 3, prepare the THF solution of polystyrene, the consumption of polystyrene is 20% (m / v) of THF;

[0034] Step 4, prepare hydrophobic silicon dioxide / polystyrene / THF mixed solution, evenly disperse hydrophobic silicon dioxide particles in the solution obtained in step 3, wherein the amount of hydrophobic silicon dioxide particles is 20% (m / v);

[0035] St...

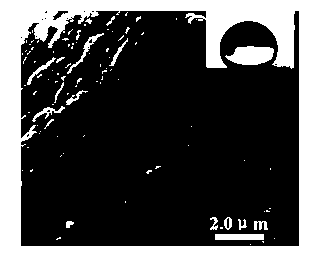

Embodiment 3

[0038] The present embodiment provides a kind of preparation method of oil-water separation filter paper, carries out according to the following steps:

[0039] Step 1. Ammonia water with a volume fraction of 15% of absolute ethanol and 10% tetraethyl orthosilicate were successively added to absolute ethanol, magnetically stirred at room temperature for 1 h, left to stand, and aged for 12 h;

[0040] Step 2: Add octadecyltrichlorosilane with a volume fraction of 0.8% ethanol to the aging mixture, stir magnetically for 2 h, wash with alcohol, centrifuge, and vacuum dry at 75°C for 4 h to prepare hydrophobic silica particles ;

[0041] Step 3, prepare the THF solution of polystyrene, the consumption of polystyrene is 40% (m / v) of THF;

[0042] Step 4, prepare hydrophobic silicon dioxide / polystyrene / THF mixed solution, evenly disperse hydrophobic silicon dioxide particles in the solution obtained in step 3, wherein the amount of hydrophobic silicon dioxide particles is 10% (m / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com