Copper foil clad laminated board with UV shielding function, adhesive and preparation methods thereof

A technology of copper-clad laminates and adhesives, applied in the field of laminates, can solve the problems of single color and inability to meet the diversity of high-performance UV-shielding copper-clad laminates, and achieve cost savings and the best comprehensive technology performance, excellent UV shielding function, and the effects of weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

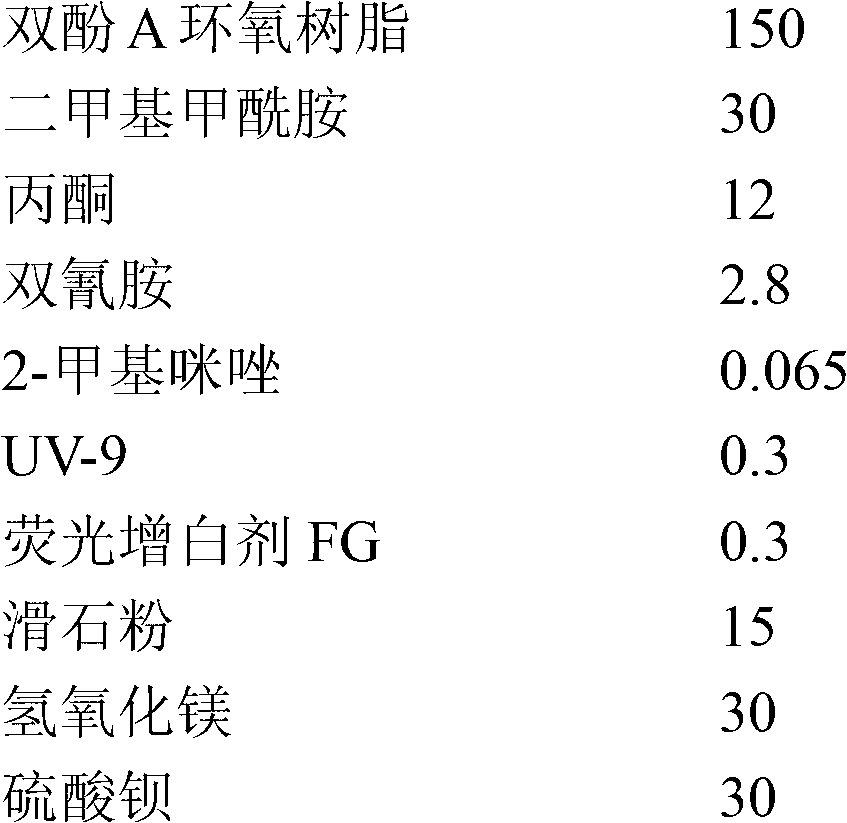

[0041] The mass parts of the specific components of the adhesive are as follows:

[0042]

[0043] The preparation method of the adhesive: mix dimethylformamide and acetone and divide it into two parts of solvent 1 and solvent 2 in proportion, wherein the mass ratio of solvent 1 and solvent 2 is 10:1; first add dicyandiamide to solvent 1 Amine and 2-methylimidazole were stirred for 4 hours at a speed of 1000rpm; then bisphenol A epoxy resin, UV-9, talcum powder, magnesium hydroxide and barium sulfate were added in sequence, and the stirring speed was 4800rpm, stirring time is 45min, to make a mixture of solvent 1; at the same time, add fluorescent whitening agent FG to solvent 2, stir at a speed of 800rpm for 3h, to make a mixture of solvent 2; finally add it to the mixture of solvent 1 in 3 batches The solvent 2 mixture was stirred at a speed of 2000 rpm for 3 hours to prepare a copper-clad laminate adhesive.

[0044] The preparation method of the copper-clad laminate: im...

Embodiment 2

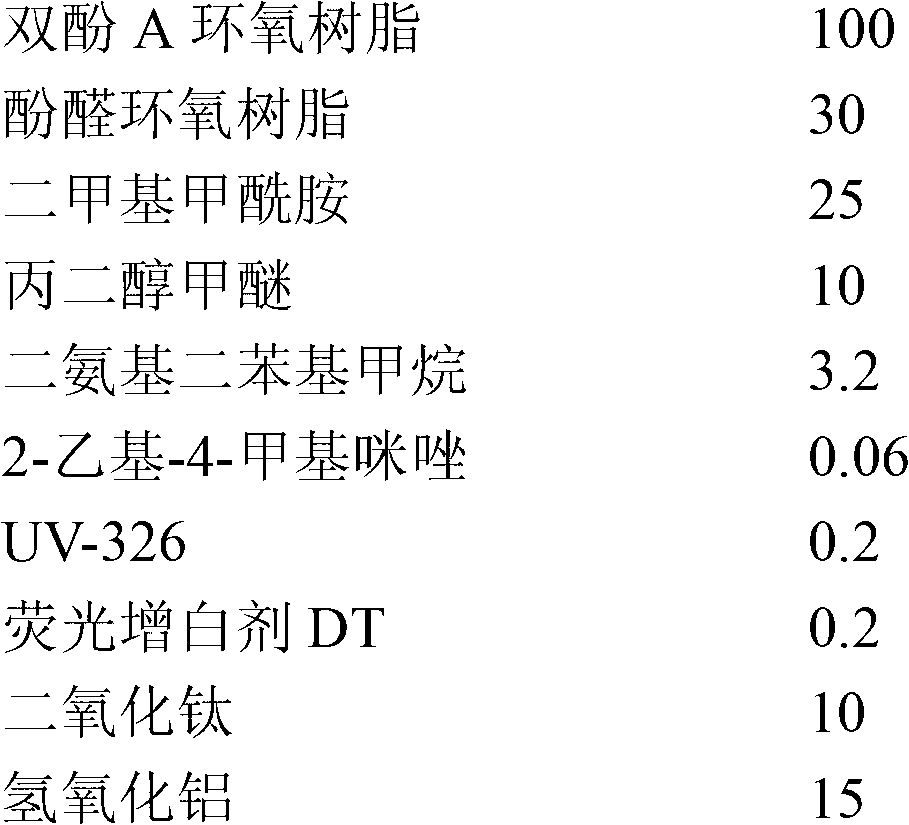

[0047] The mass parts of the specific components of the adhesive are as follows:

[0048]

[0049] The preparation method of the adhesive: mix dimethylformamide and propylene glycol methyl ether and divide it into two parts according to the proportion of solvent 1 and solvent 2, wherein the mass ratio of solvent 1 and solvent 2 is 15:1; Diaminodiphenylmethane, 2-ethyl-4-methylimidazole, stirred at a speed of 800rpm for 6h; then add bisphenol A epoxy resin, novolak epoxy resin, UV-326, titanium dioxide, aluminum hydroxide, Using high-shear dispersion stirring, the stirring speed is 4000rpm, and the stirring time is 45min to make a solvent 1 mixture; at the same time, add fluorescent whitening agent DT to solvent 2, and stir at a speed of 600rpm for 3h to make a solvent 2 mixture; finally The solvent 2 mixture was added to the solvent 1 mixture in two batches, and stirred at a speed of 2000 rpm for 2 hours to prepare an adhesive for copper-clad laminates.

[0050] The prepar...

Embodiment 3

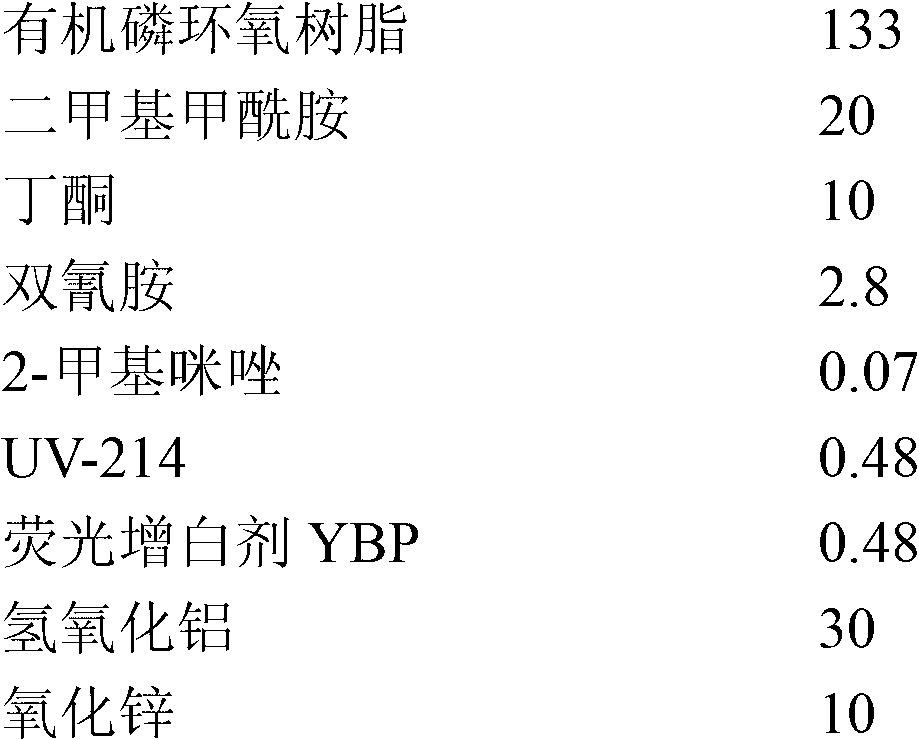

[0053] The mass parts of the specific components of the adhesive are as follows:

[0054]

[0055] The preparation method of the adhesive: mix dimethylformamide and methyl ethyl ketone and divide them into two parts of solvent 1 and solvent 2 in proportion, wherein the mass ratio of solvent 1 and solvent 2 is 7.5:1; Cyanamide and 2-methylimidazole were stirred for 4 hours at a speed of 1000rpm; then organophosphorus epoxy resin, UV-214, aluminum hydroxide, and zinc oxide were added in sequence, and high-shear dispersion stirring was adopted at a stirring speed of 4000rpm. The time is 45min to make a mixture of solvent 1; at the same time, add fluorescent whitening agent YBP to solvent 2, stir at a speed of 800rpm for 3h to make a mixture of solvent 2; finally add the solvent to the mixture of solvent 1 in 3 batches 2 mixture, stirred at a speed of 1500rpm for 3h to prepare a copper-clad laminate adhesive.

[0056] The preparation method of copper-clad laminate: impregnate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com