Preparation method of polyvinylidene-fluoride-base temperature-sensitive resistance material with negative temperature coefficient effect

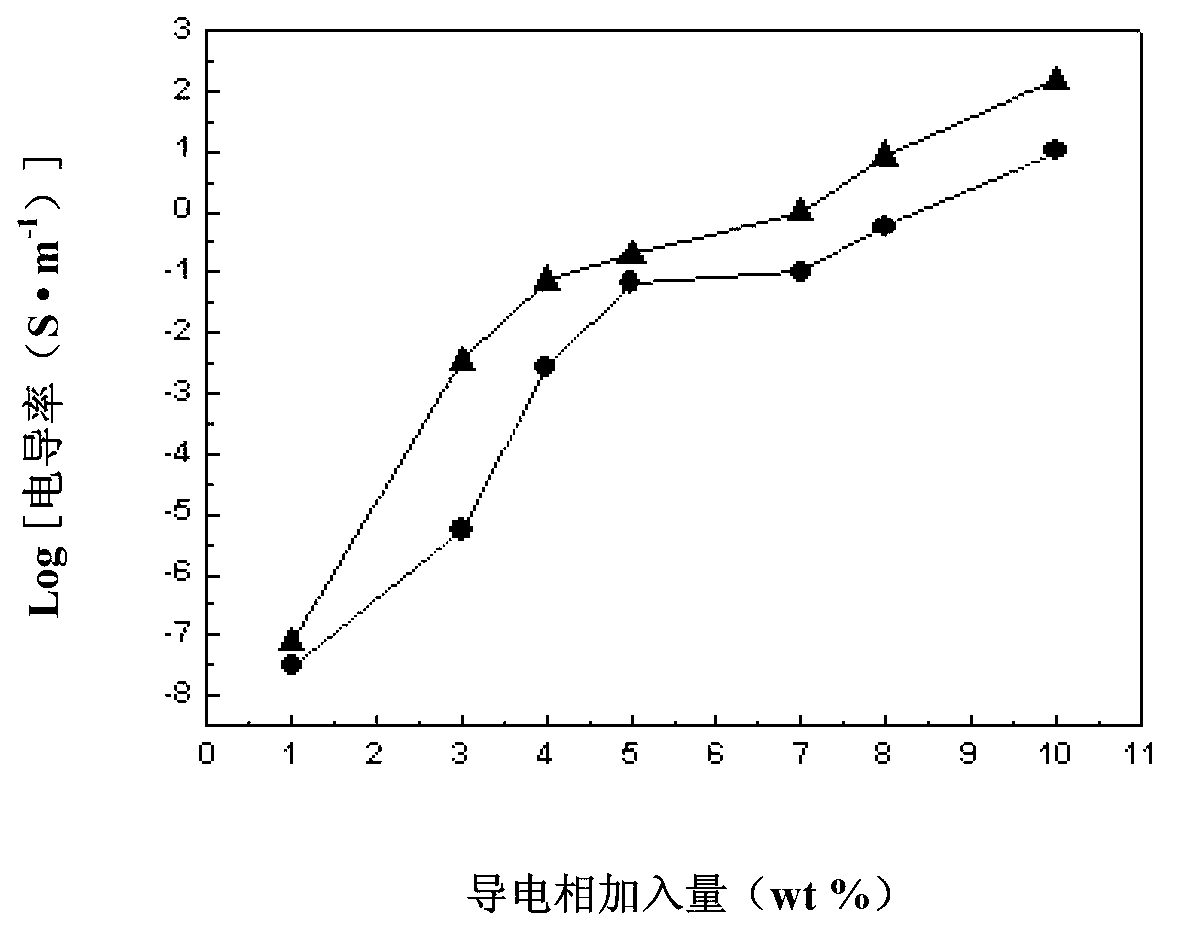

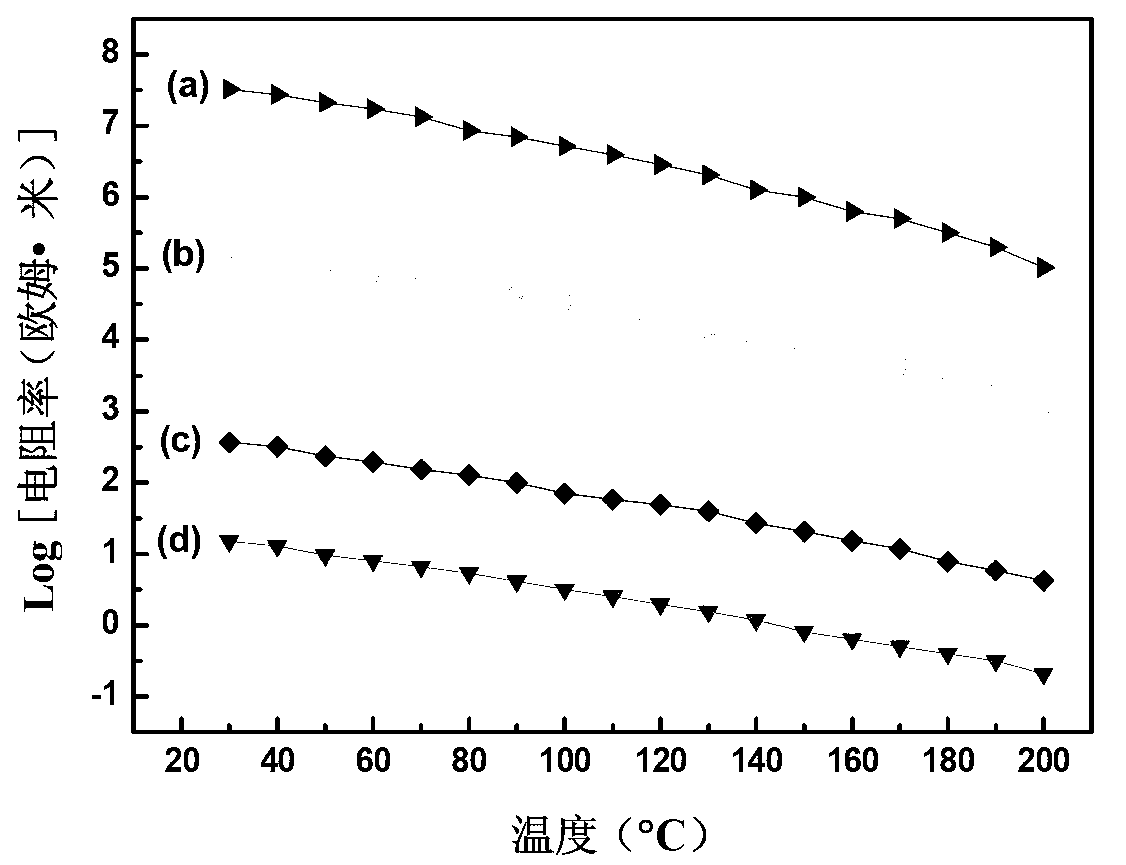

A polyvinylidene fluoride, negative temperature coefficient technology, applied in the direction of resistors with negative temperature coefficient, can solve the problems of low sensitivity, high filling amount of conductive phase, large room temperature resistivity, etc., to achieve low room temperature resistivity, high Effect of polymer-based negative temperature coefficient strength, simple temperature measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0023] Specific Embodiment 1: The preparation method of the polyvinylidene fluoride-based thermistor material with negative temperature coefficient effect in this embodiment is realized according to the following steps:

[0024] 1. Using graphite powder as raw material, the improved Hummers method is used to prepare graphite oxide;

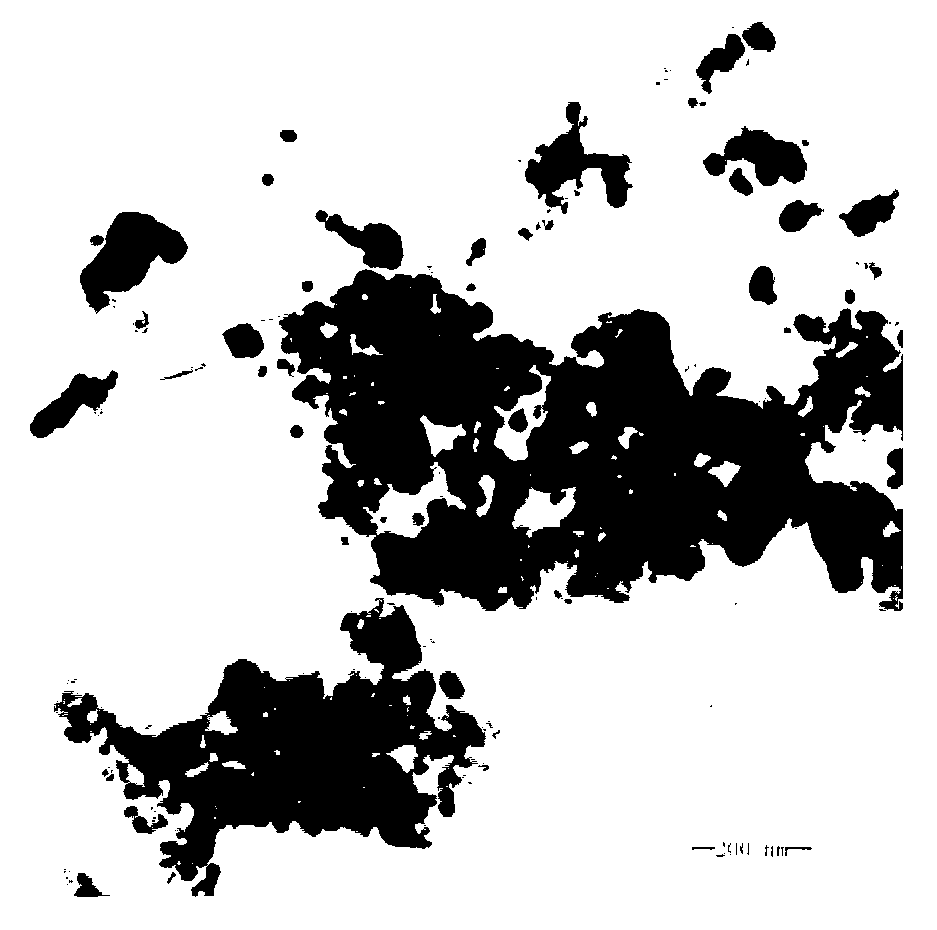

[0025] 2. Add the graphite oxide prepared in step 1 to N,N-dimethylformamide, and disperse it ultrasonically for 1~3h to obtain N,N-dimethylformamide of graphene oxide with a concentration of 0.1~1.0mg / mL Formamide dispersion Ⅰ;

[0026]3. Add 5~200mg of initiator azobisisobutyronitrile, 0.1~5g of sodium p-styrenesulfonate and 20~100mL of N,N-dimethylformaldehyde of graphene oxide prepared in step 2 in the four-necked bottle Amide dispersion I, and then pass inert protective gas into the four-necked bottle for 10~30min, then heat to 60~80℃ in a water bath under magnetic stirring, continue to react for 6~24h, and then use a microporous filter with...

specific Embodiment approach 2

[0030] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 2, N, N-dimethylformamide dispersion I of graphene oxide with a concentration of 0.3-0.8 mg / mL is obtained. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0031] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step three, add initiator azobisisobutyronitrile 10 ~ 100mg, sodium p-styrene sulfonate 1 ~ 4g and 30-90 mL of graphene oxide N,N-dimethylformamide dispersion I prepared in step 2. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity at room temperature | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com