Method for synthesizing novel industrial copper extracting agent

The technology of a copper extractant and synthesis method, which is applied in the directions of oxime preparation and organic chemistry, can solve problems such as high price and achieve the effect of low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

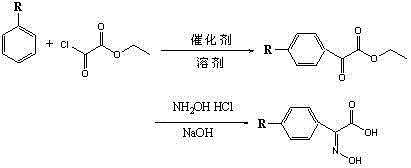

Method used

Image

Examples

Embodiment 1

[0015] Step 1: Add 8.6g of linear alkylbenzene (take dodecylbenzene as an example), 13.0g of monoethyl oxalate chloride and 50.0ml of dichloromethane into a dry 250mL three-necked flask, stir at low temperature for 30min to obtain deep Yellow homogeneous system, then add 15.2g of catalyst (take anhydrous aluminum trichloride as an example) into the three-necked flask in batches within 2h, then keep the temperature at 5°C and react for 8h. After the reaction, the reaction solution was slowly poured into 150mL concentrated hydrochloric acid and water (V 浓盐酸 :V 水 =1:1) for acid hydrolysis, the acid hydrolysis temperature does not exceed 20°C, after the acid hydrolysis is complete, transfer it to a separatory funnel, wash with 20mL water each time until the water is nearly neutral, and use 30 mL of dichloromethane was extracted three times, the aqueous phase was discarded, and the organic phases were combined. The organic phase was dried with anhydrous magnesium sulfate for 4 h....

Embodiment 2

[0018] Step 1: Add 8.6g of linear alkylbenzene (take dodecylbenzene as an example), 13.0g of monoethyl oxalate chloride and 50.0ml of dichloromethane into a dry 250mL three-necked flask, stir at low temperature for 30min to obtain deep Yellow homogeneous system, then add 16.5g of catalyst (take anhydrous aluminum trichloride as an example) into the three-necked flask in batches within 2h, then, maintain the temperature at 10°C, and react for 8h. After the reaction, the reaction solution was slowly poured into 150mL concentrated hydrochloric acid and water (V 浓盐酸 :V 水 =1:1) for acid hydrolysis, the acid hydrolysis temperature does not exceed 20°C, after the acid hydrolysis is complete, move it to a separatory funnel, wash it with 100mL of water for several times, until the water is nearly neutral, and let it stand The liquid was separated, and the aqueous phase was extracted three times with 30 mL of dichloromethane, the aqueous phase was discarded, and the organic phases were...

Embodiment 3

[0021] Step 1: Add 8.6g of linear alkylbenzene (take dodecylbenzene as an example), 13.0g of monoethyl oxalate chloride and 50.0ml of dichloromethane into a dry 250mL three-necked flask, stir at low temperature for 30min to obtain deep Yellow homogeneous system, then add 16.5g of catalyst (take anhydrous aluminum trichloride as an example) into the three-necked flask in batches within 2h, then keep the temperature at 20°C and react for 8h. After the reaction, the reaction solution was slowly poured into 150mL concentrated hydrochloric acid and water (V 浓盐酸 :V 水 =1:1) for acid hydrolysis, the acid hydrolysis temperature does not exceed 20°C, after the acid hydrolysis is complete, move it to a separatory funnel, wash it with 100mL of water for several times, until the water is nearly neutral, and let it stand The liquid was separated, and the aqueous phase was extracted three times with 30 mL of dichloromethane, the aqueous phase was discarded, and the organic phases were combi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com