Method for preparing vanadium pentoxide cathode nano-material of lithium-ion battery

A technology of vanadium pentoxide nanometer, lithium ion battery, applied in vanadium oxide, battery electrode, nanotechnology and other directions, can solve the problems of poor cycle stability, high synthesis cost, large energy consumption, etc., and achieves short time consumption and production cost. Low, simple device effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

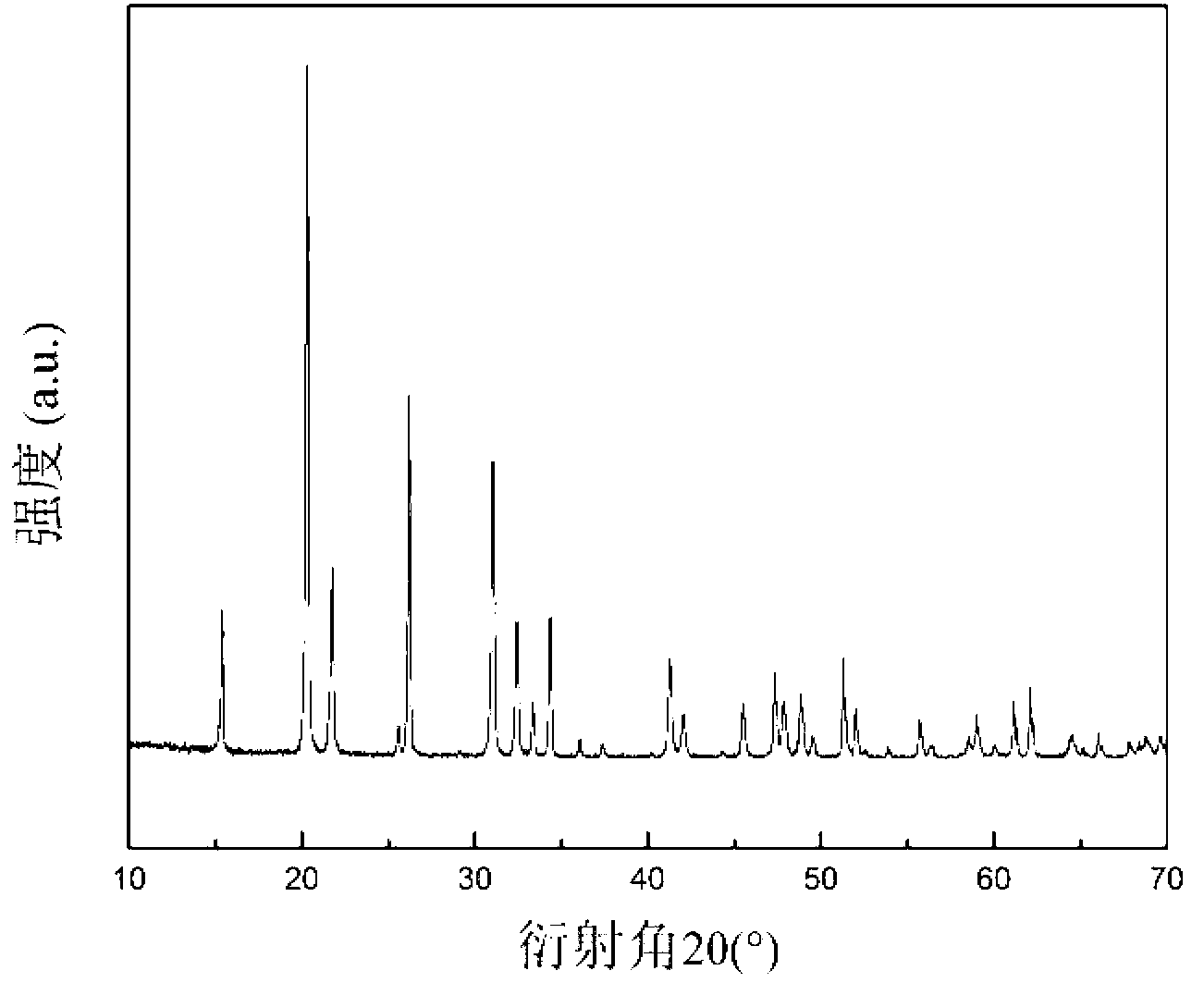

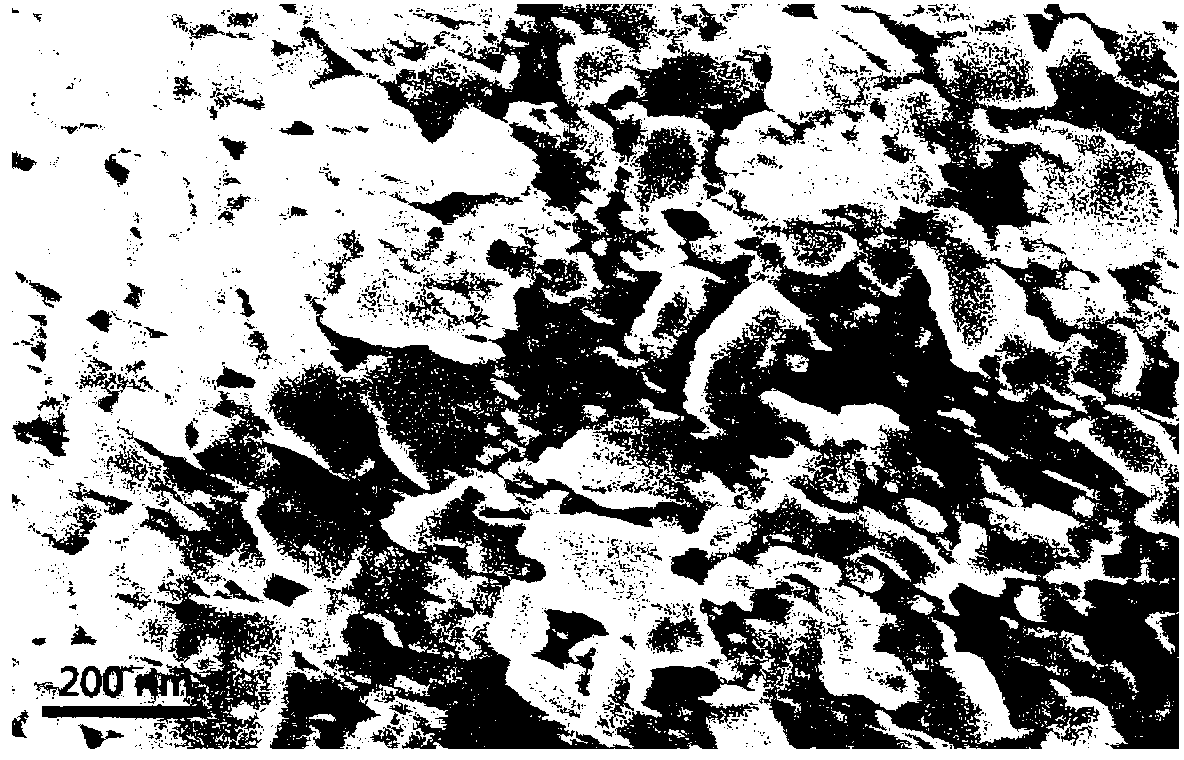

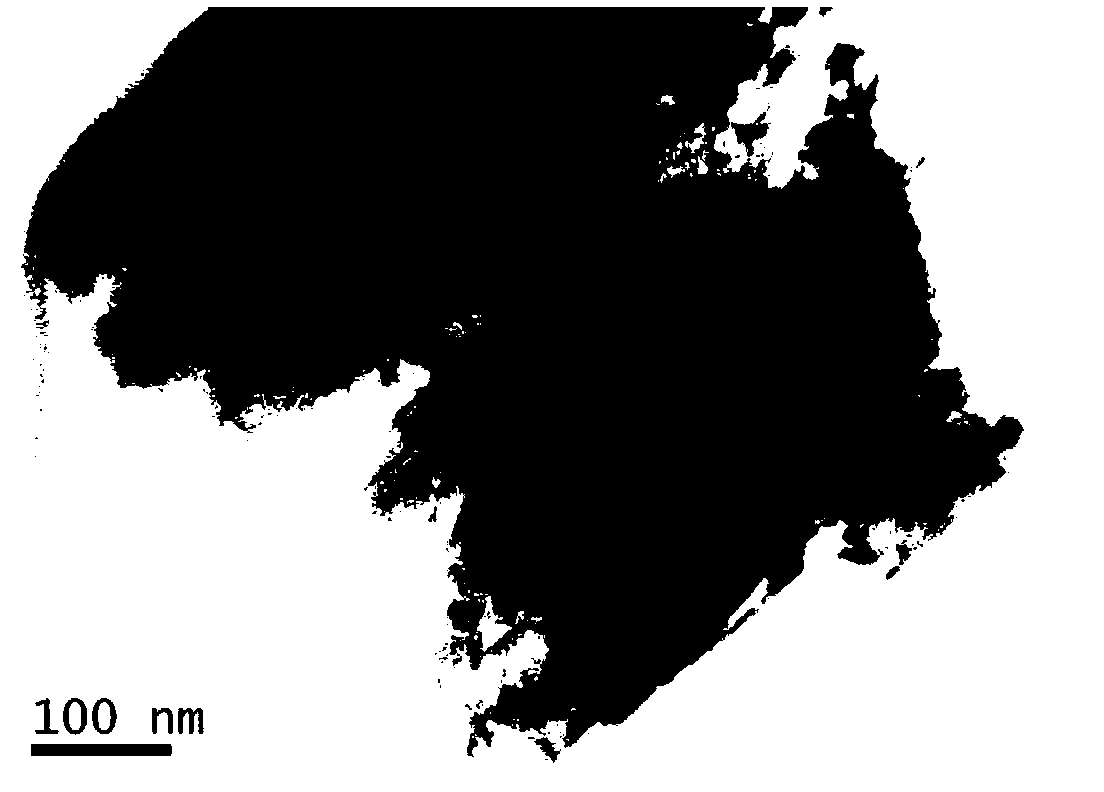

[0027] Add 0.364g vanadium pentoxide powder into 30mL hydrogen peroxide solution with a mass fraction of 15%, stir until vanadium pentoxide is completely dissolved to form a red perovanadic acid solution, and generate a large amount of gas and heat, continue stirring at room temperature After 2 hours, the solution was dried at 70°C to form a vanadium pentoxide gel to obtain a solid precursor. The precursor was heated to 400°C at a heating rate of 5°C / min in air and kept at 400°C for 2 hours. After cooling to room temperature, vanadium pentoxide nanometer material is obtained. figure 1 Shown is the XRD spectrum of the vanadium pentoxide prepared in Example 1. The obtained peaks are consistent with the cards, and the synthesized vanadium pentoxide belongs to the orthorhombic crystal system and the space group Pmmm. figure 2 Shown is the SEM picture of the vanadium pentoxide prepared by embodiment 1, image 3 Shown is the TEM picture of the vanadium pentoxide prepared in Examp...

Embodiment 2

[0030] Add 0.5g vanadium pentoxide powder into 10mL hydrogen peroxide solution with a mass fraction of 15%, stir until vanadium pentoxide is completely dissolved to form a red perovanadic acid solution, and generate a large amount of gas and heat, continue stirring at room temperature After 6 hours, the solution was dried at 40°C to form a vanadium pentoxide gel to obtain a solid precursor. The precursor was heated to 250°C at a heating rate of 1°C / min in air and kept at 250°C for 6 hours. After cooling to room temperature, vanadium pentoxide nanometer material is obtained.

Embodiment 3

[0032] Add 0.5g vanadium pentoxide powder into 15mL hydrogen peroxide solution with a mass fraction of 10%, stir until the vanadium pentoxide completely dissolves to form a red perovanadic acid solution, and generate a large amount of gas and heat, continue stirring at room temperature After 4 hours, the solution was dried at 60°C to form a vanadium pentoxide gel to obtain a solid precursor. The precursor was heated to 500°C at a heating rate of 10°C / min in air and kept at 500°C for 0.5 hours. After cooling to room temperature, vanadium pentoxide nanometer material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com