Stereoscopic thermal transfer membrane and preparation method and thermal transfer method thereof

A technology of thermal transfer film and transfer film, which is applied in chemical instruments and methods, temperature recording methods, lamination devices, etc., and can solve problems such as complex manufacturing process and low yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

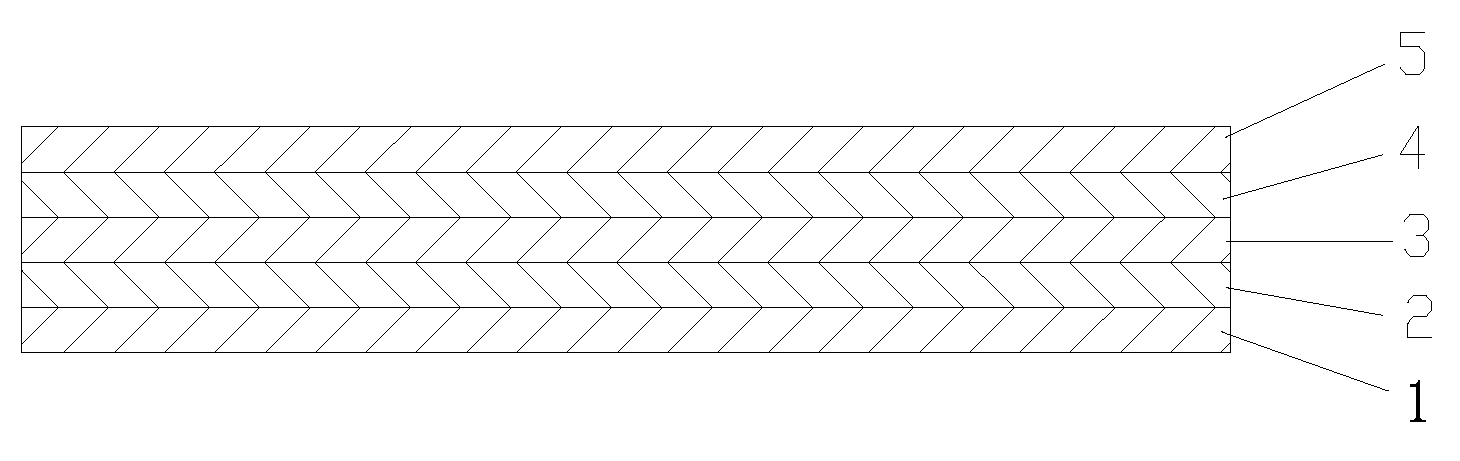

[0035] Such as figure 1 As shown, the three-dimensional thermal transfer film of a preferred embodiment provided by the present invention comprises sequential

[0036] Laminated polyethylene terephthalate (PET) base layer 1, elastic coating with release effect 2,

[0037] Hard coating 3 , printing layer 4 and secondary curing type hot melt layer 5 . In this embodiment, the temperature resistance of the PET film 1 can be baked at 100 degrees Celsius, and the slow-drying solvent can be quickly discharged. The elastic coating 2 is an elastic film formed by silicon-modified polyurethane emulsion or silicon-modified acrylic emulsion or silicon-modified polyurethane acrylate, which has good elasticity and comes with a release function. No sanding is required after transfer. With PET and elastic film as the carrier, the ink can be baked at a higher temperature during the printing process, so that the transfer film can adapt to high temperature transfer printing, thereby improving ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com