Punching machine capable of punching continuous conveying materials

A punching machine and punching technology, applied in the direction of metal processing, etc., can solve the problems of high production cost, difficult maintenance, and affecting the speed of bag making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Describe its implementation details below in conjunction with accompanying drawing:

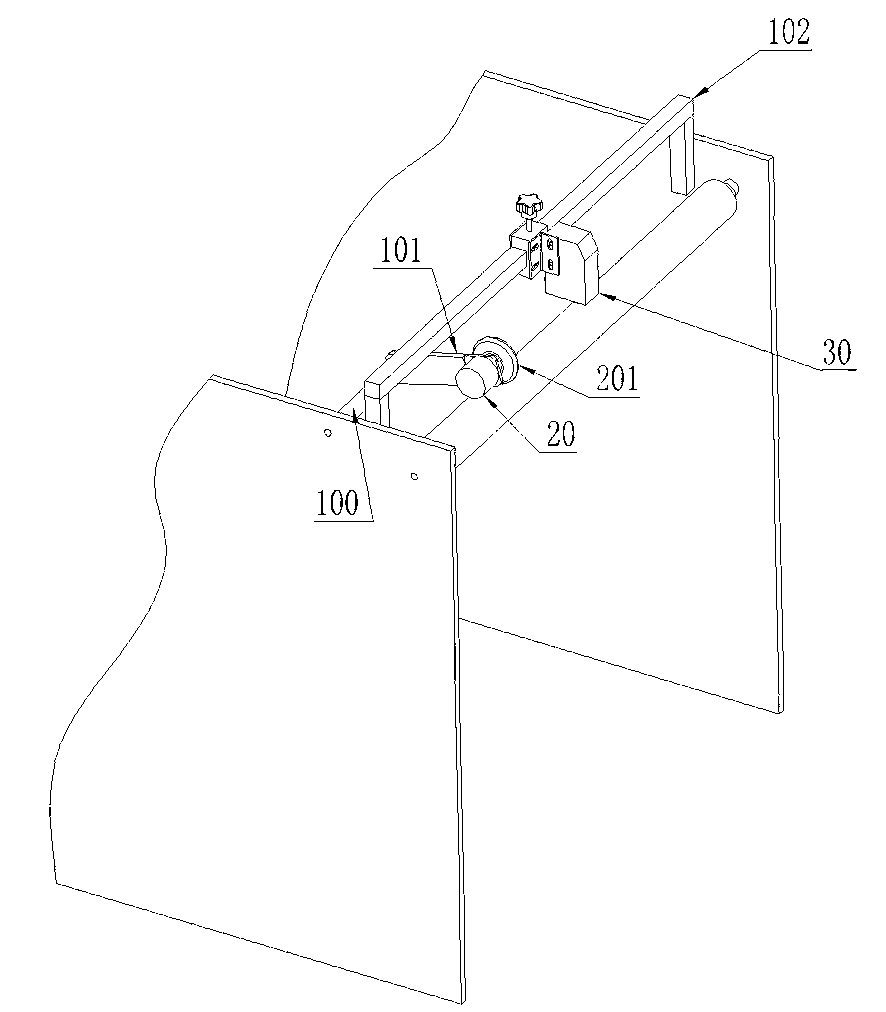

[0017] Taking a bag making machine as an example, the punching machine includes a bag making frame 10 , an encoder 20 , a photoelectric detector 30 and a punching device 40 .

[0018] Such as figure 1 As shown, the frame 10 is provided with a strut 100, one end of the strut 100 is provided with a first support plate 101, the first support plate 101 is fixed with an encoder 20, and the shaft of the encoder 20 is provided with a rotatable roller 201 , and the roller 201 is placed on the material 50; when the material 50 runs, the roller 201 rolls, and at the same time, the roller 201 drives the encoder 20, thereby calculating the running length of the material 50. The frame 10 is also provided with a second support plate 102, and the second support plate 102 is provided with a photodetector 30; when the material 50 was running, the pattern printed on the material 50 passed under the pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com