An optical fiber distribution cabinet

A technology of optical fiber wiring and optical fiber, which is applied in the field of optical fiber distribution cabinets, can solve problems such as cross-winding and fast search of unfavorable optical fibers, and achieve the effects of improving efficiency, shortening troubleshooting time, and facilitating troubleshooting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

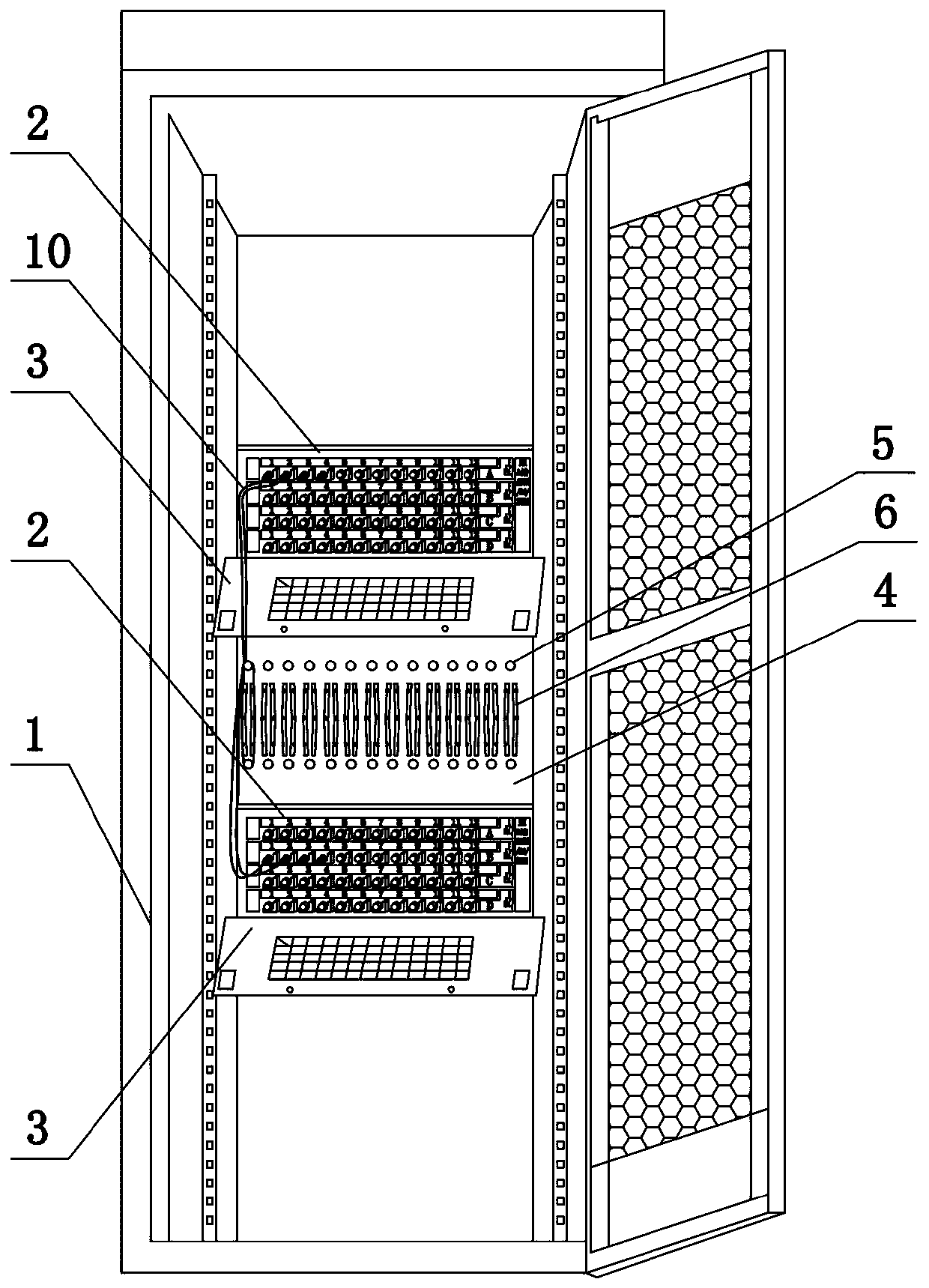

[0045] Such as figure 1 and figure 2 As shown, an optical fiber distribution cabinet in this embodiment includes a cabinet body 1, two distribution frames 2 arranged in the cabinet body 1, an optical fiber protection plate 3 installed on each distribution frame 2, and an optical fiber protection panel 3 Reserve wiring spacing between board 3 and distribution frame 2;

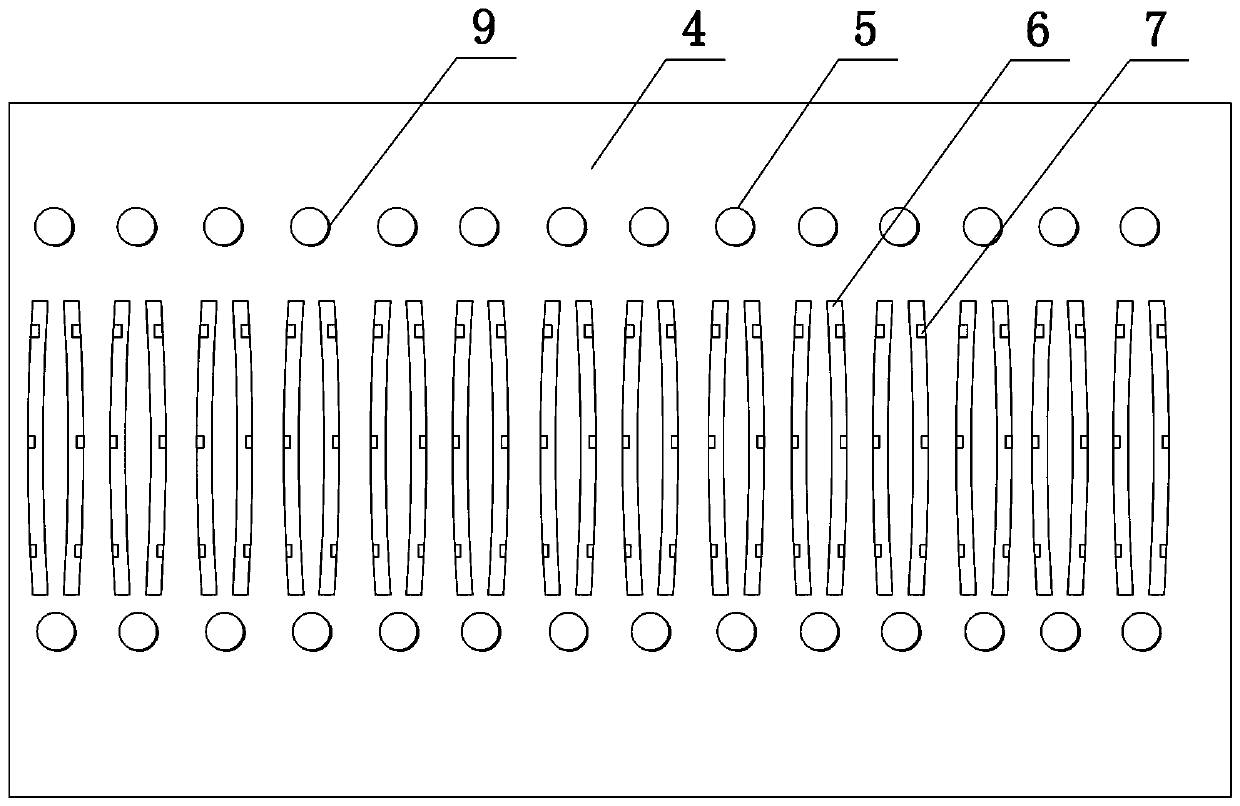

[0046]A winding mechanism is arranged between adjacent distribution frames 2, and the winding mechanism includes a winding plate 4, a plurality of winding posts 5 fixed on the winding plate 4 by threads or bolts, and a plurality of winding posts 5 set on the winding plate 4. The wire management groove 6 and the wire winding plate 4 are made of PVC plastic insulation board. The wire winding post 5 is integrally formed on the end face of the wire winding board 4. 5, every two cable management grooves 6 are a group, respectively adopt the arc combination of inner buckle type, which matches the shape of the oute...

Embodiment 2

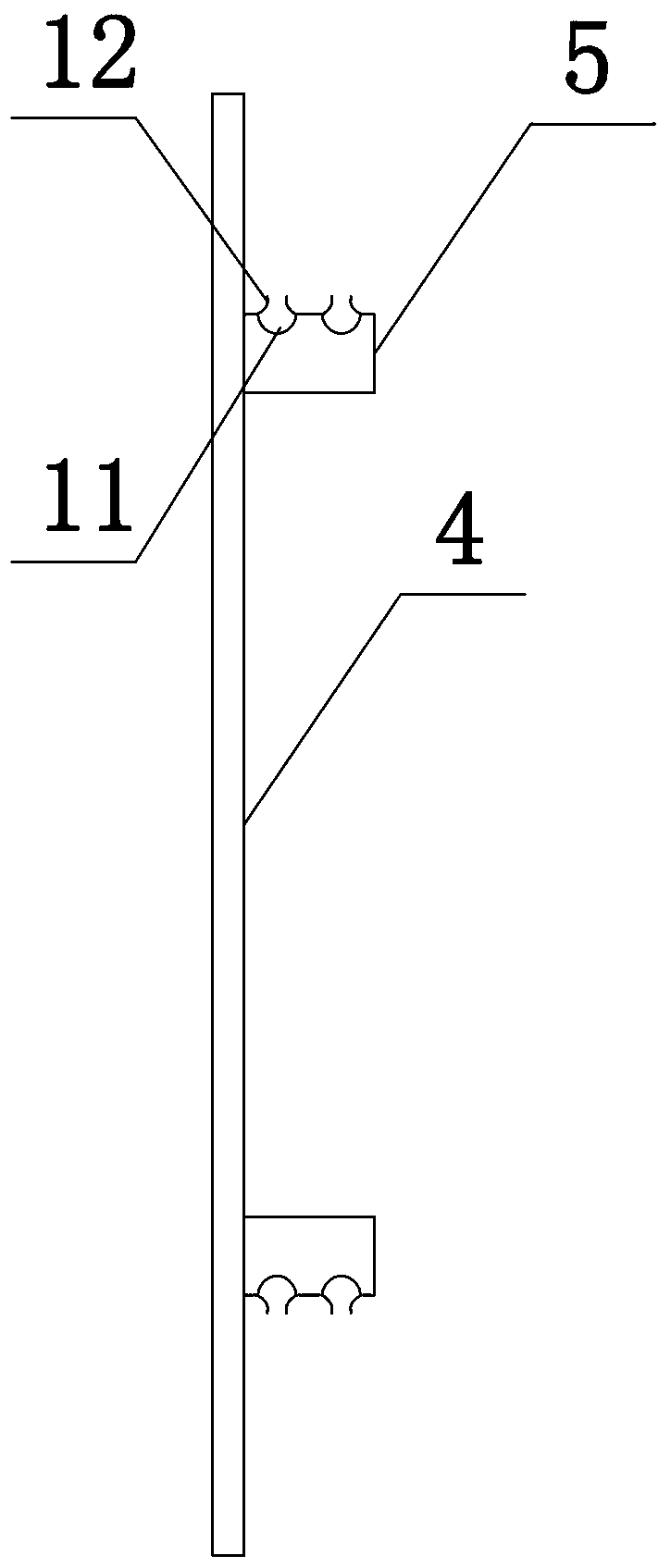

[0059] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as image 3 As shown, the outer surface of the winding column 5 is provided with a plurality of winding grooves 11 matching the outer diameter of the optical fiber along its axial direction, and arc-shaped guide plates 12 are arranged on both sides of the winding groove 11, and the two sides of the same winding groove 11 The distance between the curved guide plates 12 is smaller than the outer diameter of the optical fiber.

[0060] Embodiment two

[0061] The structure of this embodiment is basically the same as that of Embodiment 2, the difference is: as Figure 4 As shown, an arc-shaped guide plate is jointly arranged between adjacent winding grooves, and the arc-shaped guide plate is a part of a circular plate or an oval plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com