Flocculent-yarn blowing and heat dissipation improved structure for circular knitting machine

A technology of circular knitting machine and heat dissipation structure, which is applied in knitting, textiles and papermaking, etc. It can solve problems such as electrical failures, inability to synchronize the rotation of the cloth receiving machine and the machine table, and the inability of the carbon brush motor 13 to control the signal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

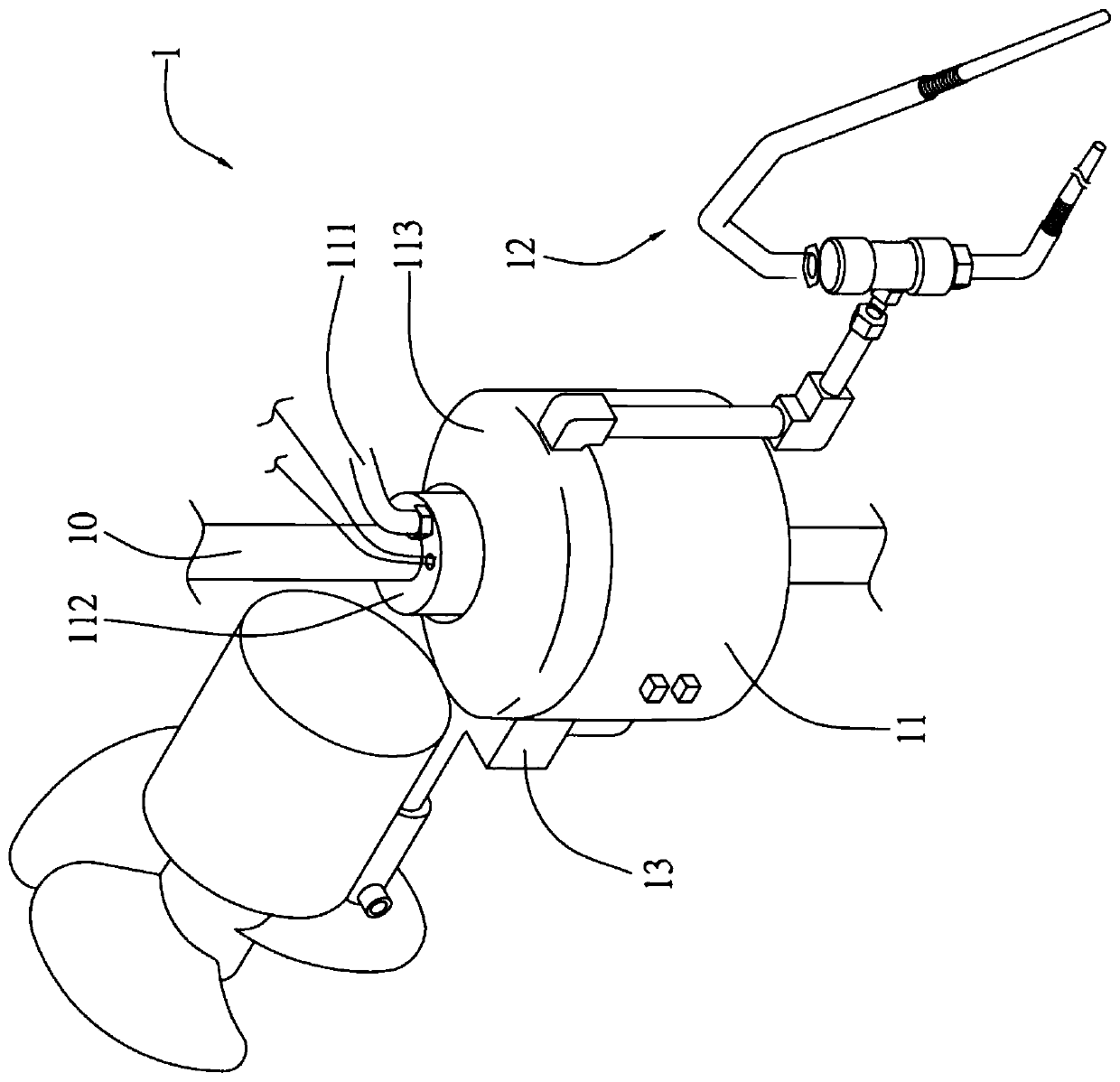

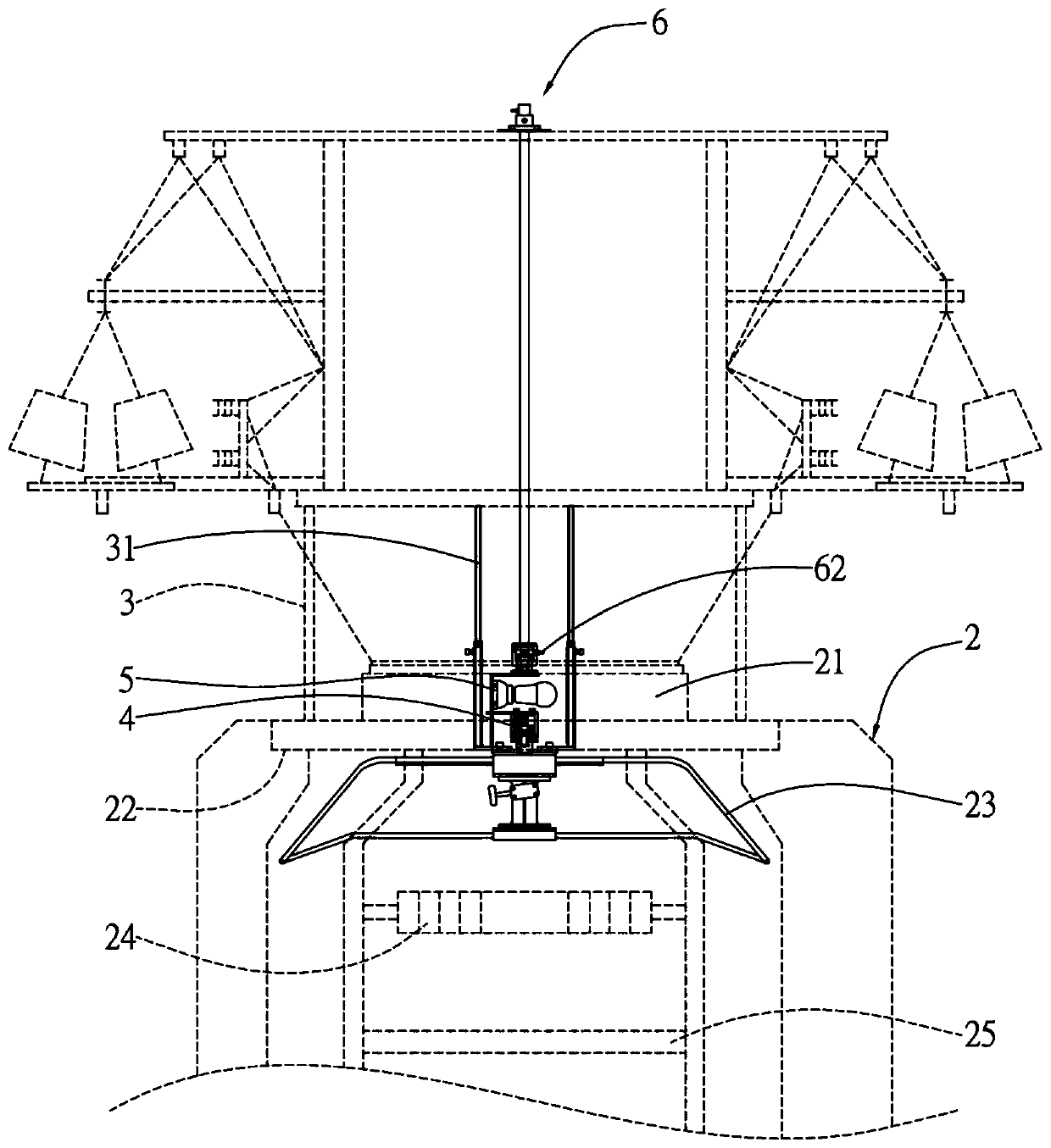

[0028] see Figure 3 to Figure 5 As shown, the structure of the present invention can be seen from the figure, which includes: a machine platform 2, a relative fixed assembly 3, a mercury seat 4, a detection device 5, and a blowing and cooling structure 6;

[0029]The top of the machine table 2 has an upper needle barrel 21, a lower needle barrel 22 with the upper needle barrel 21 connected, and a space for knitted cloth is formed between the bottom of the upper needle barrel 21 and the inner wall of the lower needle barrel 22, and a fabric support frame is extended at the bottom of the bottom 23. A fabric pulling rod 24 and a cloth rolling rod 25 are correspondingly arranged below a cloth support frame 23; a spaced telescopic frame 31 protrudes on both sides of the outer edge of the aforementioned upper needle barrel 21 relative to the fixed assembly 3, and each telescopic frame 31 A telescopic tube 32 is arranged along the telescopic direction, and a plurality of adjusting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com