Board complex having a polylactic acid cover

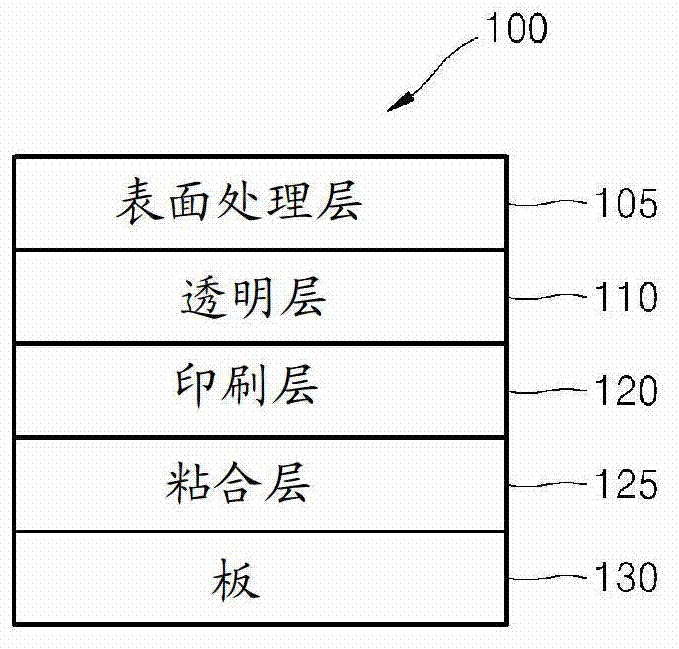

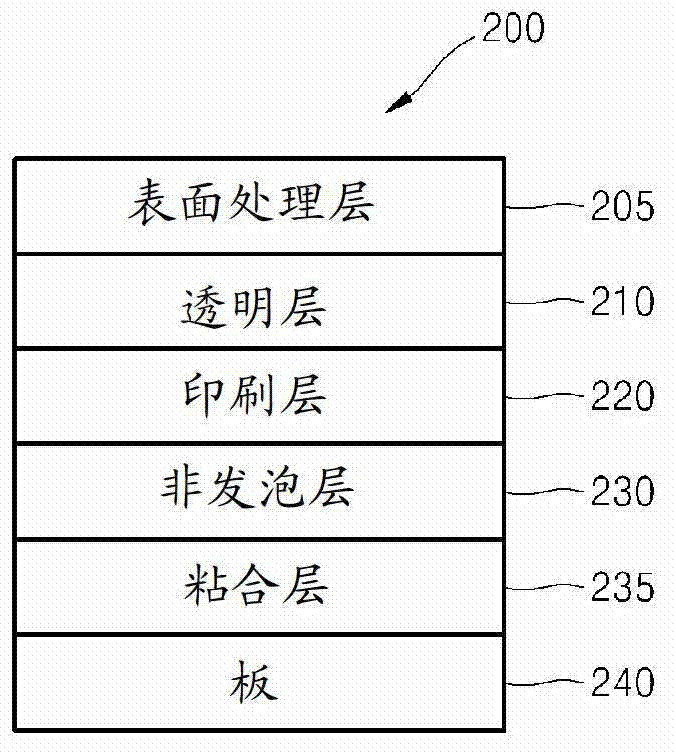

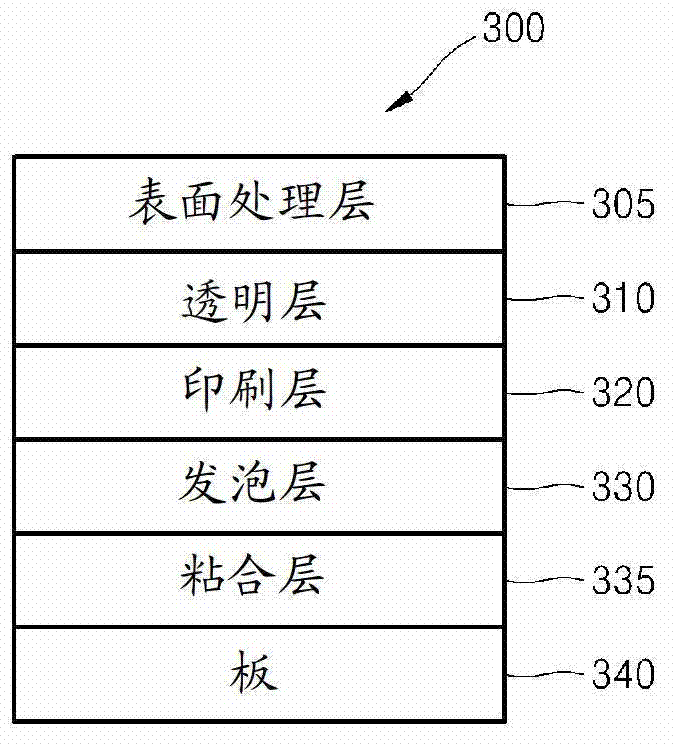

A technology of composite materials and covering materials, which is applied in the field of forming board composite materials by using polylactic acid, which is an environmentally friendly resin, can solve problems such as low strength and cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0118] Preparation of transparent layer

[0119] Using an extruder, 100 parts by weight of polylactic acid resin 2002D (manufactured by Natli Vox (Nature Works), melt index: less than 3), 20 parts by weight of acetyl tributyl citrate, 10 parts by weight of Acrylic acid copolymer, 5 parts by weight of stearic acid, and 5 parts by weight of carbodiimide were kneaded for the first time, and after kneading at 140°C using an internal mixer, they were mixed for the first time using two rollers at 140°C. Mix a second time. Thereafter, the prepared raw material was calendered at a temperature of 130° C. to prepare a sheet with a thickness of about 0.6 mm.

[0120] Preparation of printing layer

[0121] Through the same process as the above-mentioned transparent layer preparation process, for 100 parts by weight of 2002D, 30 parts by weight of acetyl tributyl citrate, 10 parts by weight of acrylic acid copolymer, 5 parts by weight of stearic acid, 5 parts by weight of di Isocyanate,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com