Qualitative and quantitative analysis method for element sulfur in liquefied petroleum gas

A technology for quantitative analysis of liquefied petroleum gas, applied in the field of analytical chemistry, can solve the problems of low analysis accuracy and sensitivity, elemental sulfur cannot be directly measured, etc., and achieve the effects of good accuracy, fast quantification and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

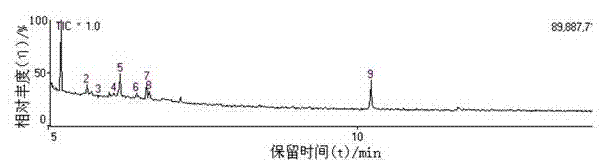

[0046] Example 1 Structural Analysis of Elemental Sulfur in Liquefied Petroleum Gas

[0047] Gas chromatography conditions:

[0048] Chromatographic column: non-polar quartz capillary column, 30m×0.25mm,

[0049] Carrier gas: high purity helium,

[0050] Head pressure: 90kPa,

[0051] Injection port temperature: 195°C,

[0052] Column temperature: the initial temperature is 70°C, keep for 2min, raise the temperature to 210°C at 40°C / min, then raise the temperature to 230°C at 6°C / min, keep for 6min.

[0053] Injection volume: 0.8 μL.

[0054] Mass Spectrometry Conditions:

[0055] Interface temperature: 210°C,

[0056] Ionization method: electron ionization (EI),

[0057] Electron energy: 70eV,

[0058] Detector voltage: 1.5kV.

[0059] With toluene as solvent, S 0 Standard sample (S 8 ) to prepare a standard solution, under the above analysis conditions, for S 0 The standard solution was scanned (SCAN) for analysis, the solvent cutting time was 4.5 min, and the sig...

Embodiment 2

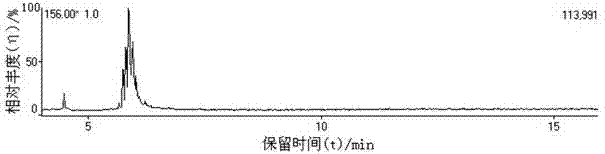

[0061] The establishment of embodiment 2 standard curve

[0062] Gas chromatography conditions:

[0063] Chromatographic column: non-polar quartz capillary column, 30m×0.25mm,

[0064] Carrier gas: high purity helium,

[0065] Head pressure: 100kPa,

[0066] Injection port temperature: 200°C,

[0067] Column temperature: the initial temperature is 60°C, keep for 2min, raise the temperature to 200°C at 35°C / min, then raise the temperature to 225°C at 5°C / min, keep for 3min.

[0068] Injection volume: 0.9 μL.

[0069] Mass Spectrometry Conditions:

[0070] Interface temperature: 220°C,

[0071] Ionization method: electron ionization (EI),

[0072] Electron energy: 70eV,

[0073] Detector voltage: 1.7kV.

[0074] 0.0100g S 0 Standard sample (S 8 ) was dissolved in 100mL toluene solution to prepare S 0 S with a mass concentration of 100mg / L 0 standard solution. The solution was diluted to 0.10, 0.50, 1.00, 10.00, 20.00 mg / L of S 0 Standard solution, add internal st...

Embodiment 3

[0078] The investigation of embodiment 3 precision

[0079] in S 0 In the standard solution with a concentration of 0.25 mg / L, the internal standard n-undecane was added to be 1.00 mg / L. Under the analytical conditions for establishing a standard curve, the solution was measured 6 times, and the standard deviation of the determination was 0.01 mg / L , the relative standard deviation is 4.0%; in S 0 In the standard solution with a concentration of 2.20 mg / L, the internal standard n-undecane was added to be 1.00 mg / L, and the solution was measured 6 times, with a standard deviation of 0.08 mg / L and a relative standard deviation of 3.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com