Polyurethane composite hard polyfoam as well as preparation method and application of polyurethane composite hard polyfoam

A technology of rigid foam and polyurethane, which is applied in the field of preparation of polyurethane composite rigid foam plastics, can solve the problems of high production cost of polyurethane rigid foam, poor heat resistance, flame retardancy, antistatic performance, etc., and achieve Excellent performance, wide range of applications, and simple process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

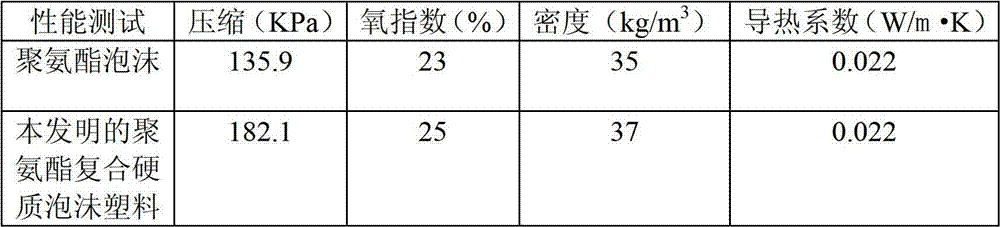

Embodiment 1

[0028] The polyurethane composite rigid foam plastic of this embodiment is composed of component A and component B, wherein component A is formed by mixing isocyanate and inorganic materials; component B is formed by mixing polyether, catalyst and foaming agent into; the weight ratio of component A to component B is component A: component B=1.1:1; wherein, in component A, the weight ratio of isocyanate to inorganic material is: (152-154): (2- 10); in component B, the weight ratio of the combined polyether, catalyst and blowing agent is: combined polyether: catalyst: blowing agent = 100:1.4:16. The catalyst is N,N-dimethylcyclohexylamine, and the blowing agent is HCFC-141b, both of which are commercially available; the inorganic material in this embodiment is sodium carbonate or barium sulfate.

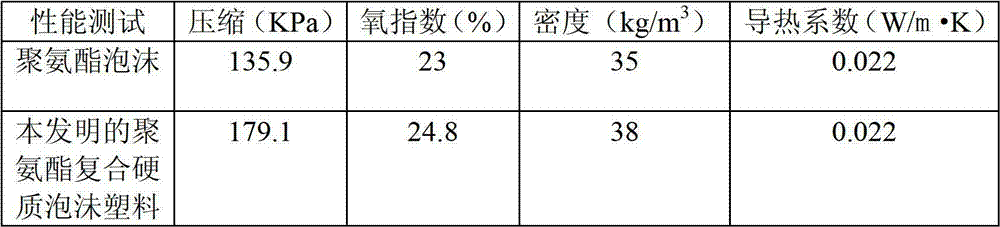

Embodiment 2

[0030] The polyurethane composite rigid foam plastic of this embodiment is composed of component A and component B, wherein component A is formed by mixing isocyanate and inorganic materials; component B is formed by mixing polyether, catalyst and blowing agent into; the weight ratio of component A to component B is component A:component B=1.3:1; wherein, in component A, the weight ratio of isocyanate to inorganic material is: (152-155): (5- 13); In component B, the weight ratio of the combination polyether, catalyst and foaming agent is: combination polyether:catalyst:foaming agent=100:1.6:(15-17). The catalyst used is dibutyltin dilaurate, and the blowing agent is HCFC-245fa; the inorganic material in this embodiment is perlite.

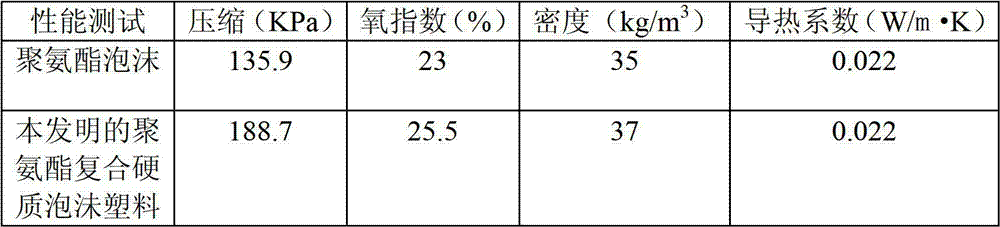

Embodiment 3

[0032] The polyurethane composite rigid foam plastic of this embodiment is composed of component A and component B, wherein component A is formed by mixing isocyanate and inorganic materials; component B is formed by mixing polyether, catalyst and foaming agent into; the weight ratio of component A to component B is component A: component B=1.4:1; wherein, in component A, the weight ratio of isocyanate to inorganic material is: (152-158): (3- 7) In component B, the weight ratio of the combined polyether, catalyst and blowing agent is: combined polyether: catalyst: blowing agent = 100:2.8: (15-17). The catalyst is dibutyltin dilaurate, and the blowing agent is pentane; the inorganic material in this embodiment is aluminum hydroxide or magnesium hydroxide.

[0033] The preparation method embodiment 1 of polyurethane composite rigid foam plastic

[0034] The preparation method of the polyurethane composite rigid foam plastic of the present embodiment may further comprise the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com