Electron radiation cross-linked polypropylene foam sheet and preparation method thereof

A technology of cross-linked polypropylene and electron irradiation, which is applied in the field of electron irradiation cross-linked polypropylene foam sheet (IXPP) and its preparation, can solve the problem that the mechanical properties of materials with a foaming ratio are difficult to meet market needs, and achieve Improved performance, fine cells, and uniform foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

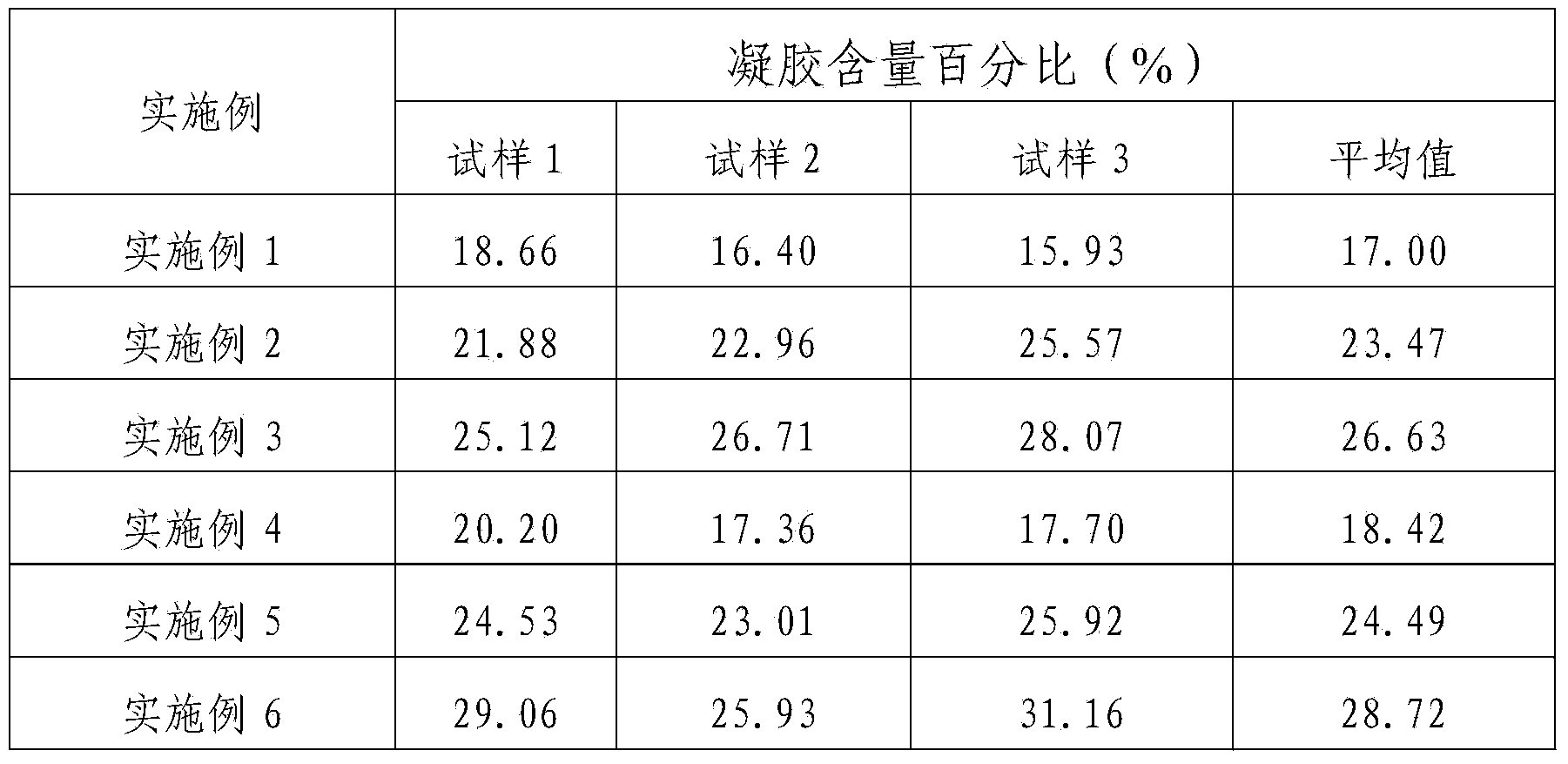

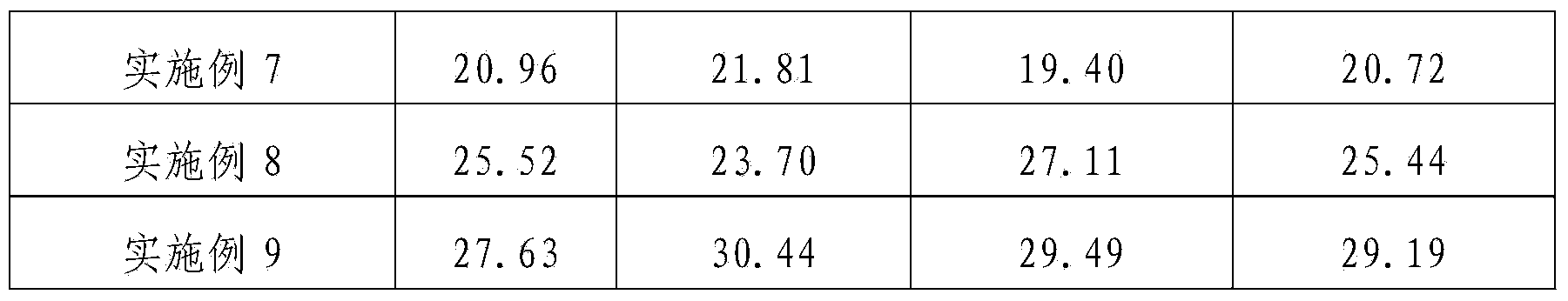

Examples

Embodiment 1

[0022] Embodiment 1 of the present invention provides an electronically irradiated cross-linked polypropylene foam sheet, which is composed of the following components in weight percentages: polypropylene resin 58%, polyethylene resin 5%, polyethylene oxide resin 12%, and crosslinking agent 7%, anti-aging agent 5%, foaming agent 7%.

[0023] Wherein, the crosslinking agent is one of isooctyl acrylate, neopentyl glycol diacrylate, and pentaerythritol triacrylate.

[0024] The anti-aging agent is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid] pentaerythritol ester.

[0025] The blowing agent is one of azodicarbonamide and p-toluenesulfonyl semicarbazide.

[0026] The preparation method of the above-mentioned electron irradiation crosslinked polypropylene foamed sheet includes the following steps in sequence:

[0027] Step [1] Mix polypropylene resin, polyethylene oxide resin, and crosslinking agent uniformly, and prepare polypropylene mixed masterbatch at 225°C;

[0028] St...

Embodiment 2

[0034] Except that the polyethylene resin content is 10%, the others are the same as in Example 1.

Embodiment 3

[0036] Except that the polyethylene resin content is 15%, the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com