Fused-rebonded magnesite-chrome brick with excellent thermal shock resistance and production process

A stable and recombined technology, applied in the field of high-grade magnesia-chrome bricks for RH refining furnaces in the metallurgical industry, can solve problems such as increased refractory process costs, unfavorable sustainable development, thermal shock stability, and poor slag resistance. Improved thermal shock resistance, reduced energy consumption, and better firing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

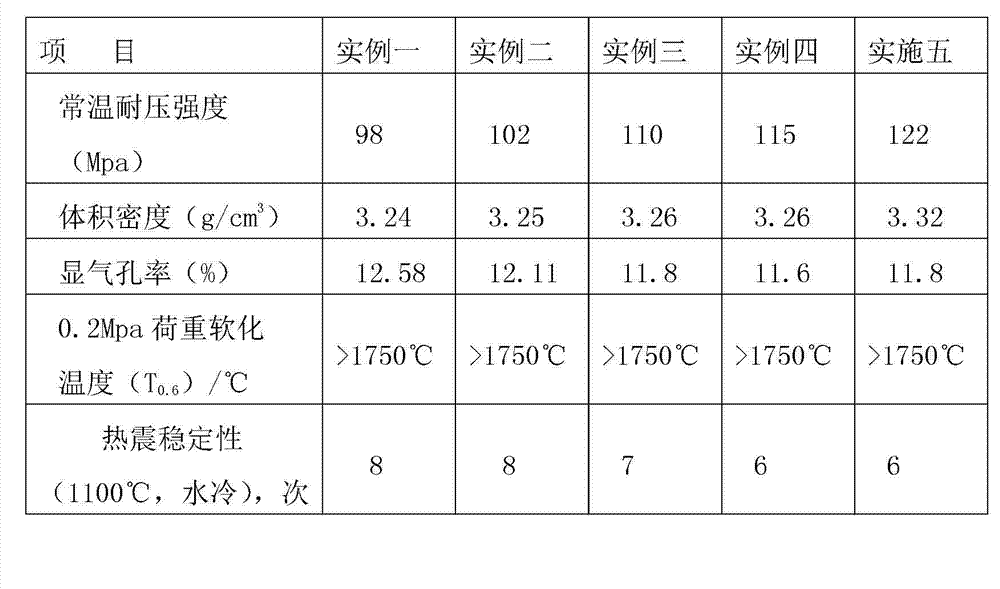

Examples

example 1

[0027] Example 1: An electro-fused rebonded magnesia-chrome brick with excellent thermal shock stability, its raw material ratio is: high-purity magnesia: 25, large crystal fused magnesia: 35, fused magnesia-chrome: 25, chromite : 10, MgCO 3 : 2. Chromium concentrate superfine powder: 3. Rare earth sintering agent: 0.5. Sulfurous acid pulp waste liquid: 3. Specific gravity δ of sulfurous acid pulp waste liquid, 1.32≥δ≥1.28g / cm 3 .

example 2

[0028] Example 2: An electro-fused rebonded magnesia-chrome brick with excellent thermal shock stability, the ratio of raw materials by weight is: high-purity magnesia: 25, large crystal fused magnesia: 20, fused magnesia-chrome: 40, Chromite: 5, MgCO 3 : 8. Chromium concentrate superfine powder: 2, 0.1 parts of rare earth sintering agent and 3 parts of sulfurous acid pulp waste liquid, the specific gravity δ of sulfurous acid pulp waste liquid, 1.32≥δ≥1.28g / cm 3 .

example 3

[0029] Example 3: An electro-fused rebonded magnesia-chrome brick with excellent thermal shock stability, the ratio of raw materials by weight is: high-purity magnesia: 15, large crystal fused magnesia: 35, fused magnesia-chrome: 30, Chromite: 13, MgCO 3 : 2, ultrafine powder of chrome concentrate: 5, 0.2 parts of rare earth sintering agent and 3 parts of sulfurous acid pulp waste liquid, the specific gravity δ of sulfurous acid pulp waste liquid, 1.32≥δ≥1.28g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com