Rigidity-controllable small grinding tool polishing disc based on magnetorheological fluid and polishing method

A magnetorheological fluid and polishing disc technology, applied in the field of advanced optical manufacturing, can solve the problems of uneven force and mismatch, and achieve the effects of high polishing quality, controllable contact area, uniform and stable force distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

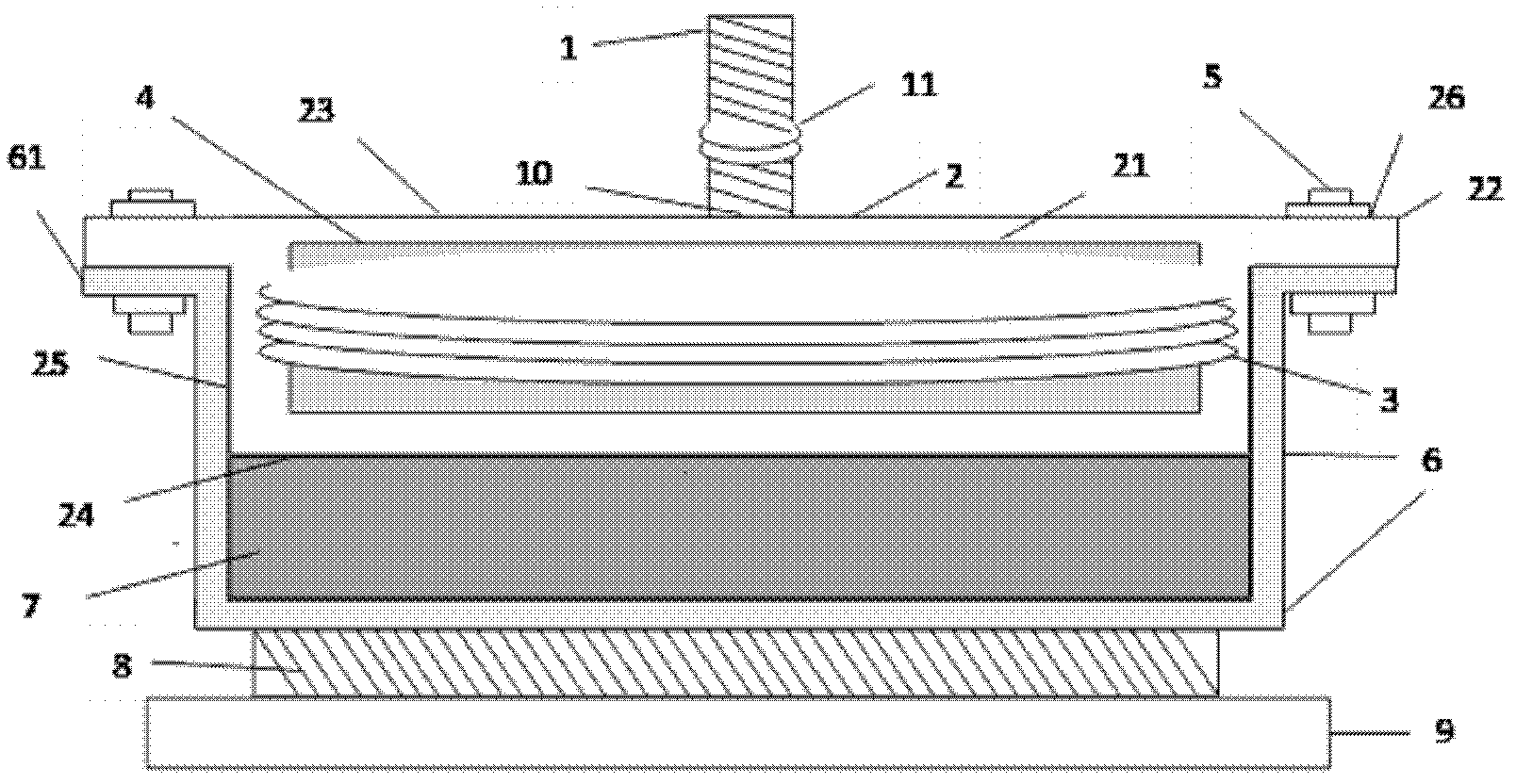

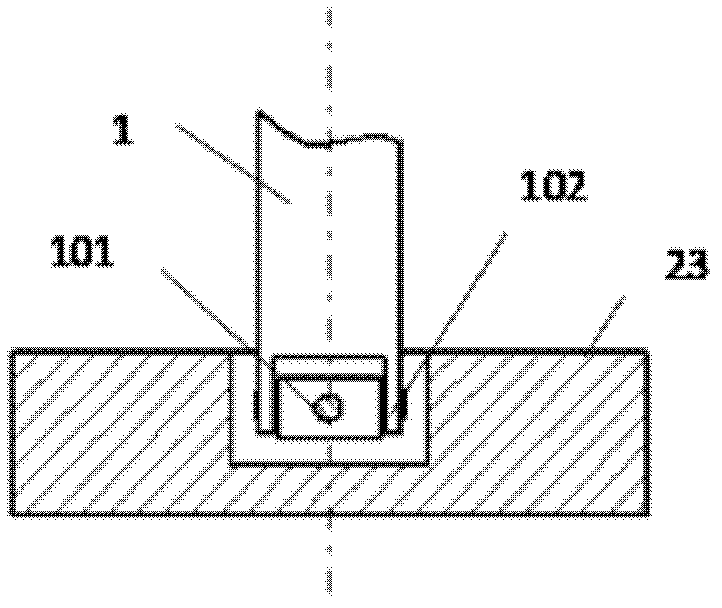

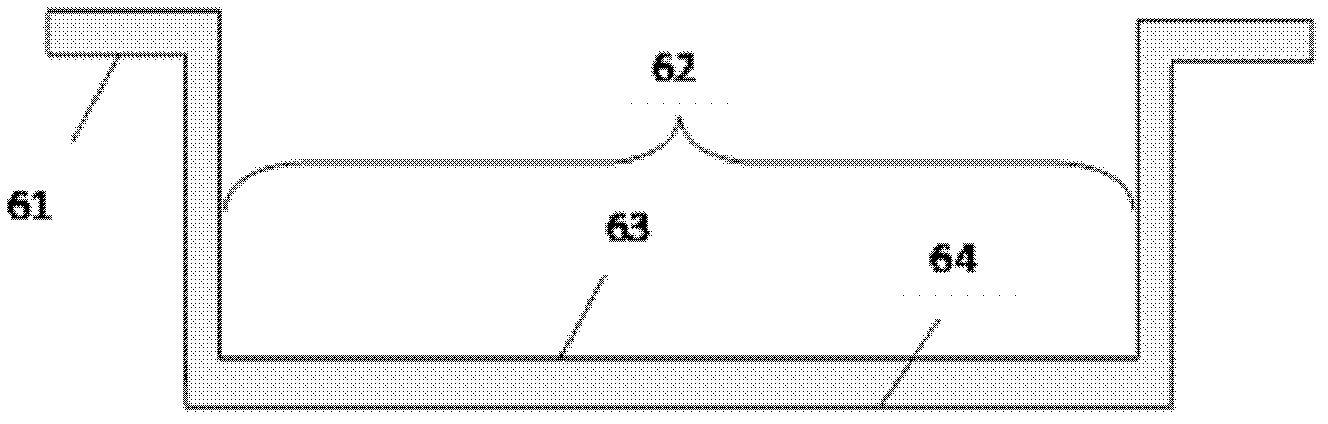

[0043] refer to Figure 1a The shown magneto-rheological fluid-based small abrasive polishing disc with controllable stiffness obtains driving force on the power shaft of any machine tool that can be clamped by the drive shaft, thereby driving the polishing disc to rotate; through the control of the current in the current coil The elastic modulus (stiffness) of the magnetorheological fluid can be adjusted to make it continuously variable from liquid to solid state, so that the polishing layer of the small abrasive polishing disc has the function of profiling and recording: the polishing layer is under the control of the shaft pressure and is polished When the surface of the workpiece is in close contact, if there is no current in the coil, the magnetorheological fluid appears liquid, and the polishing layer is deformed to match the surface shape of the workpiece. This p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com