Leaf Spring Suspension System of Airbag Lifting Axle Structure and Vehicle

A technology of suspension system and structural plate, applied in the direction of suspension, elastic suspension, motor vehicles, etc., can solve the problems of difficult control of leaf spring stiffness, cargo transportation safety accidents, uneven load distribution, etc., and increase the cargo capacity , save fuel, improve the effect of adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

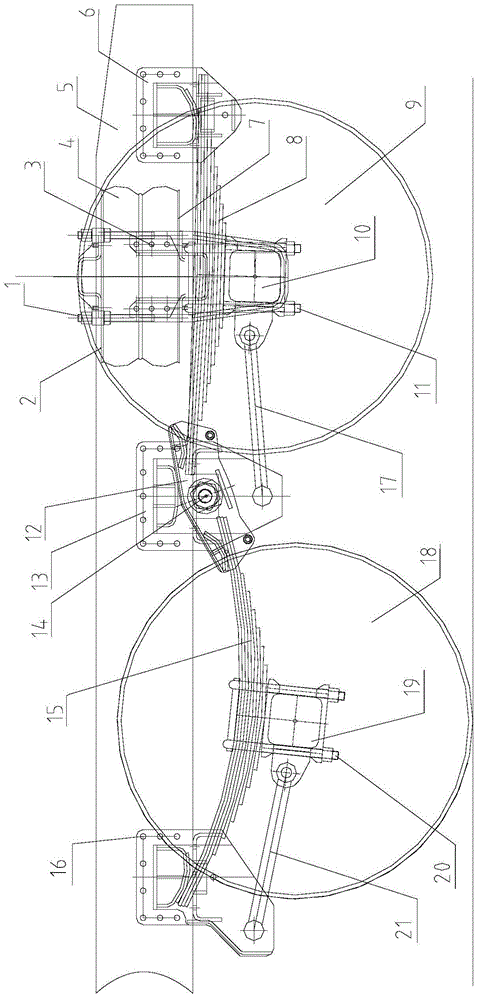

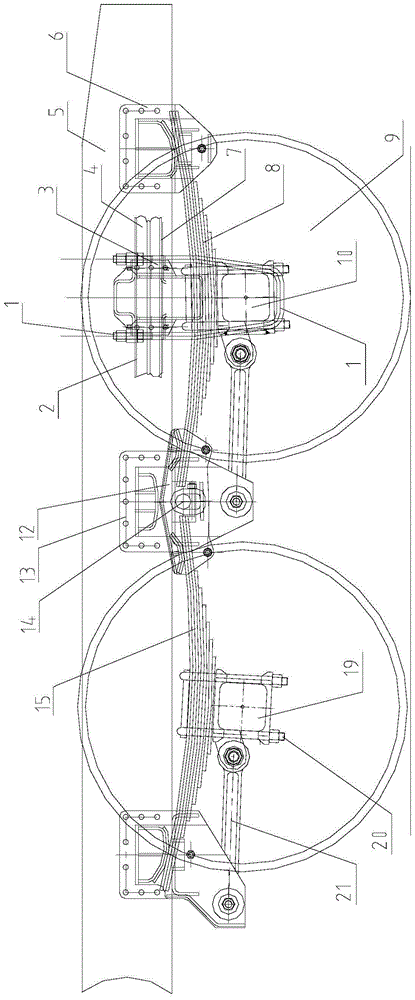

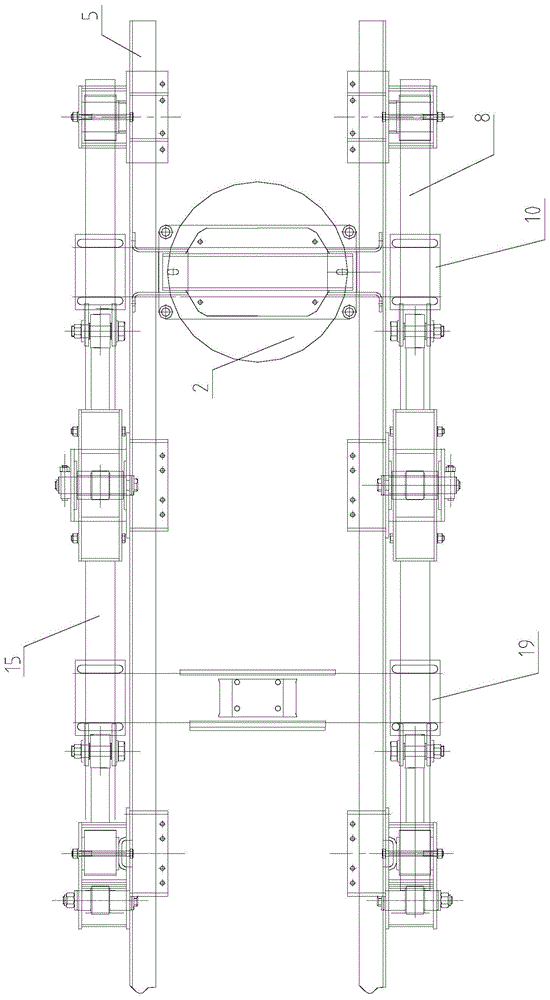

[0034] Such as figure 1 As shown, the airbag lifting bridge structure leaf spring suspension system of the present invention comprises: airbag 4, balance beam 12, first leaf spring 8, second leaf spring 15, first thrust rod 17, second thrust rod 21 and respectively successively The leaf spring front bracket 16 , the leaf spring middle bracket 13 , the air bag mounting bracket 3 and the leaf spring rear bracket 6 installed on the vehicle frame 5 . Wherein, an airbag upper cover plate 2 is installed above the airbag 4, and an airbag lower cover plate 7 is installed below the airbag 4, and the airbag upper cover plate 2 and the airbag lower cover plate 7 are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com