All-position flux-cored wire for alkaline gas protection

A technology of flux-cored welding wire and alkaline gas, which is applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of low-temperature impact toughness decline, etc., and achieve the improvement of welding performance, the reduction of deposited metal impurities, and the reduction of welding spatter Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] The invention is an alkaline slag-based flux-cored welding wire. The outer surface of the welding wire is wrapped with SPCC or a low-carbon steel strip with similar performance, and the cross-sectional shape is O-shaped butt joint or lap joint. The steel strip is rolled into a semicircle, and then a powder mixture with a specific ratio is added, then sealed and then reduced to 1.2mm by drawing. The drug core includes slagging agent, arc stabilizing agent, deoxidizer, and a certain amount of alloying agent and iron powder are also added. The above flux cores are mixed evenly in a certain proportion and then added to the welding wire. Several typical formulas are listed below, and the corresponding filling rate is 20%.

[0007]

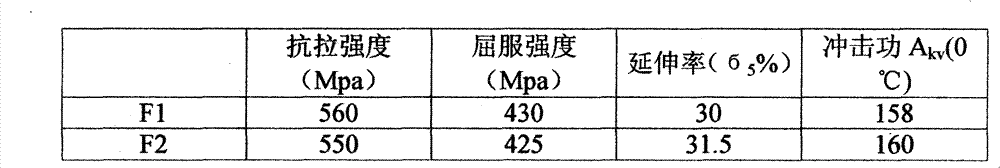

[0008] Tests show that F1 and F2 have better all-position welding performance, while F3 and F4 cannot perform all-position welding. The mechanical properties of F1 and F2 are as follows;

[0009]

[0010] Professionals can make many chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com