Surface treatment method for protecting superfine raw solder powder, and superfine powder solder paste prepared according to method

A technology for surface treatment and solder powder, applied in the field of ultra-fine powder solder paste and solder paste preparation technology, can solve the problems of high welding defect rate and poor wettability, and achieve low welding defect rate, good stability and high quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 6

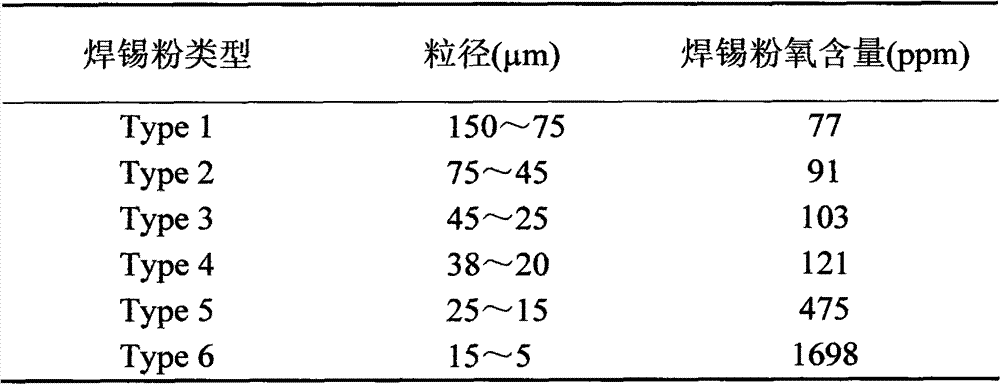

[0051] Embodiment 1~Example 6 The surface treatment method of the original powder of superfine solder powder of the present invention

[0052] Proceed as follows:

[0053] a) Prepare the original powder of ultra-fine solder powder;

[0054] b) Use an organic acid treatment agent to treat the oxides on the surface of the ultra-fine solder powder, so that the oxygen content of the ultra-fine solder powder is lower than 150ppm to obtain a semi-finished product A;

[0055] c) The semi-finished product A is further treated with an anti-oxidation treatment agent to form a complex film on the surface of the semi-finished product A to obtain a semi-finished product B; the purpose of this step is to prevent the semi-finished product A from being oxidized again.

[0056] d) Dry the semi-finished product B in an oven at 30-40°C, and pack it with nitrogen gas to obtain superfine solder powder. Refer to Table 2 for the organic acid treatment agent and treatment time, and refer to Table 3...

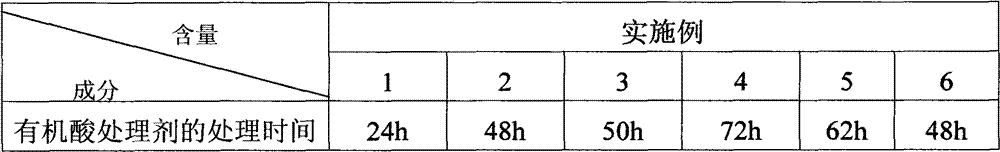

Embodiment 1

[0057] The organic acid treatment of the surface of the former powder of ultrafine solder powder of the embodiment of the present invention 1-6 of table 2

[0058]

[0059]

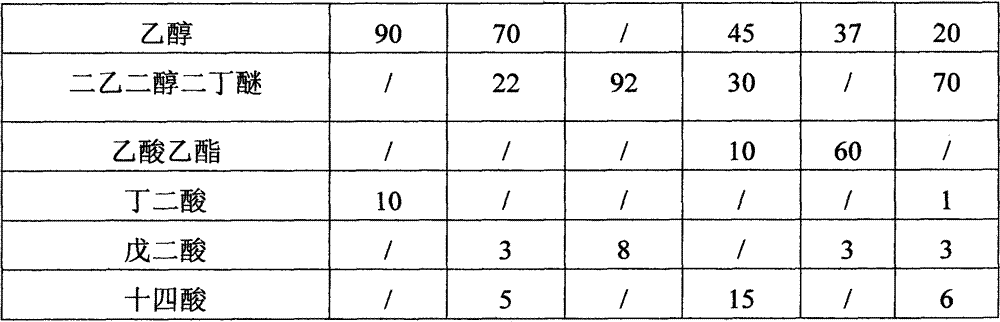

[0060] Antioxidant treatment on the surface of the former powder of ultrafine solder powder of the embodiment of the present invention 1-6 of table 3

[0061]

[0062] In order to make those skilled in the art fully understand the surface treatment method of the original powder of ultrafine solder powder of the present invention and the preparation process of ultrafine solder paste, the inventor only uses the surface treatment method of the original powder of ultrafine solder powder in Embodiment 1 and Example 3 The process and the preparation process of ultra-fine solder paste are described in detail as follows. In other embodiments, the surface treatment process of the original powder of ultra-fine solder powder and the preparation process of ultra-fine solder paste can refer to the processes de...

Embodiment 3

[0065] The processing of the former powder of superfine solder powder in embodiment 3

[0066] First, 8 parts by weight of glutaric acid and 92 parts by weight of diethylene glycol dibutyl ether were uniformly stirred with a disperser to prepare an organic acid treatment solution. Then pour the original powder of Sn99.0Ag0.3Cu0.7 ultrafine solder powder with a particle size of 1 to 25 μm into a stainless steel container, and then pour the organic acid treatment solution prepared above. The amount of the treatment solution is to immerse the original ultrafine solder powder and Make sure that the ultra-fine solder powder is not exposed to the air, stir slowly with a stirring rod for 3 to 5 minutes, and then treat it statically for 50 hours. After the treatment is completed, pour out the supernatant to obtain a semi-finished product A; % Methylimidazole 50% acetone 45% ethanol solution, the amount added is to immerse the semi-finished product A and keep the semi-finished product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com