Machining method of nano column/needle forest structure

A processing method and nano-pillar technology, applied in nanotechnology, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of poor structural controllability, limited application of nano-pillar/needle forest structure integration, difficult single-layer bead patterning Arrangement and other issues to achieve the effect of uniform distribution and graphic preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

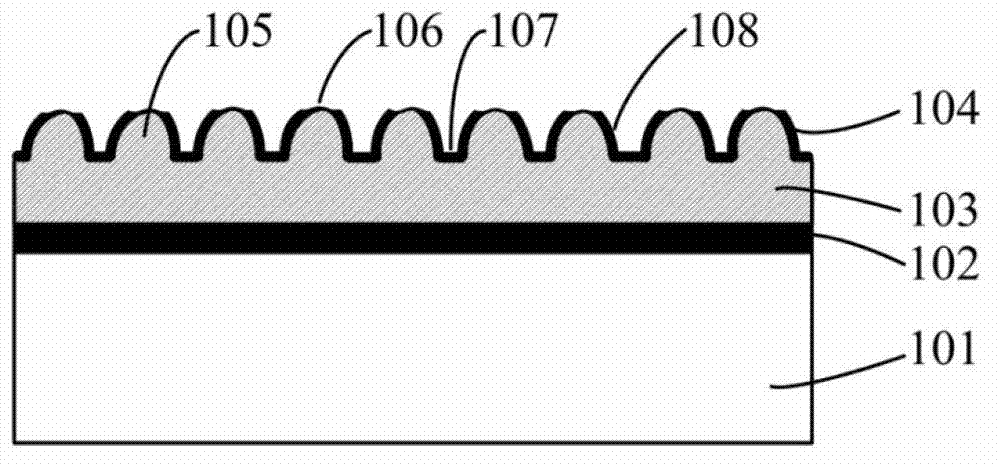

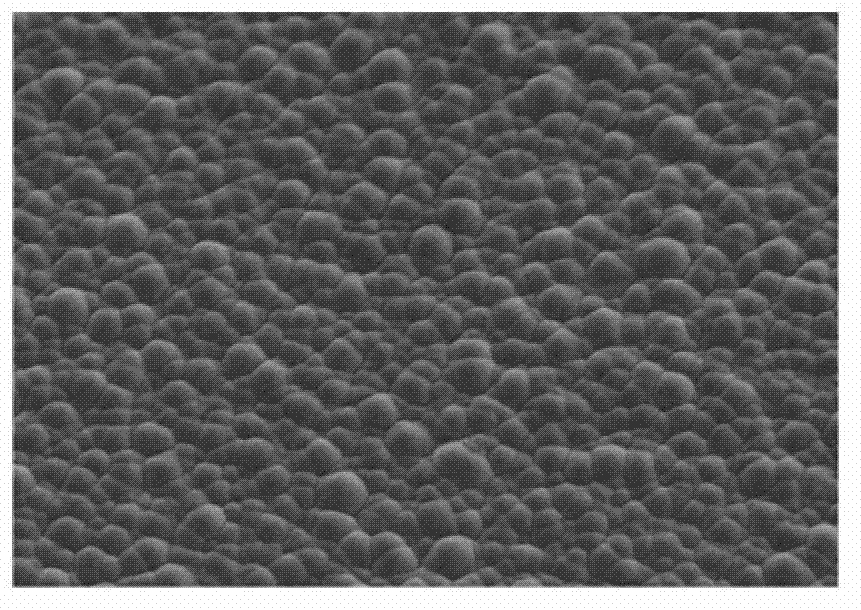

[0040] like figure 1 As shown, the thermal oxidation technology is used to grow and etch the isolation layer 102 on the substrate 101, and the substrate 101 is made of single crystal silicon; The thickness is 5000?; the polysilicon layer 103 with a thickness of 2 μm is grown by LPCVD technology. The temperature of the furnace tube for preparing the polysilicon layer 103 by LPCVD method is 620° C., the pressure is 300 mTorr, and the silane flow rate is 100 sccm (standard-state cubic centimeter per minute), Due to the large thickness of the polysilicon layer 103 , nano-bulges 105 are formed on the surface thereof, thus presenting a rough surface. A side wall material layer 104 with a thickness of 2000 ? is grown on the polysilicon layer 103 by LPCVD technology. During the deposition process, a TEOS (Tetraethyl Orthosilicate) source is used. The source temperature is 50°C and the furnace tube temperature is 720°C , the pressure is 300mTorr, O 2 The flow rate is 200 sccm. Becau...

Embodiment 2

[0045] like figure 1 As shown, on the substrate 101, PECVD (plasma enhanced chemical vapor deposition) technology is used to grow and etch the isolation layer 102, and the PECVD deposits and grows SiO 2 The temperature of the furnace tube is 270°C, the power is 103W, the pressure is 250mTorr, the silane flow rate is 300sccm, accounting for 4.6% of the total gas, N 2 The flow rate of O is 150 sccm, and the thickness of the etching isolation layer 102 is 5000 Å; the polysilicon layer 103 with a thickness of 1.5 μm is grown by PECVD technology, and the furnace tube temperature of the PECVD polysilicon layer 103 is 270°C, the power is 170W, the pressure is 400mTorr, and silane SiH 4 The flow rate is 300 sccm, because the thickness of the polysilicon layer 103 is relatively large, nano-bulges 105 are formed on its surface, so the surface is rough; on the polysilicon layer 103, a side wall material layer 104 with a thickness of 1500 Å is grown by PECVD, and the side wall is grown b...

Embodiment 3

[0050] like figure 1 As shown, a polysilicon layer 103 with a thickness of 2 μm is directly grown on the substrate 101 by LPCVD technology. The furnace tube temperature of the LPCVD polysilicon layer 103 is 620° C., the pressure is 300 mTorr, and the flow rate of silane is 100 sccm. Since the polysilicon layer 103 is relatively thick, Nano bulges 105 are formed on its surface, so the surface is rough; on the polysilicon layer 103, a side wall material layer 104 with a thickness of 2000 ? 720°C, the furnace tube pressure is 300mTorr, O 2 The flow rate is 200 sccm. Because of the existence of the nano-bulge 105, the sidewall material layer 104 forms SiO on the sidewall of the nano-bulk 105. 2sidewall 108, and the SiO 2 The thinnest, SiO in the first gap 107 of the nanobulge 105 2 thickest.

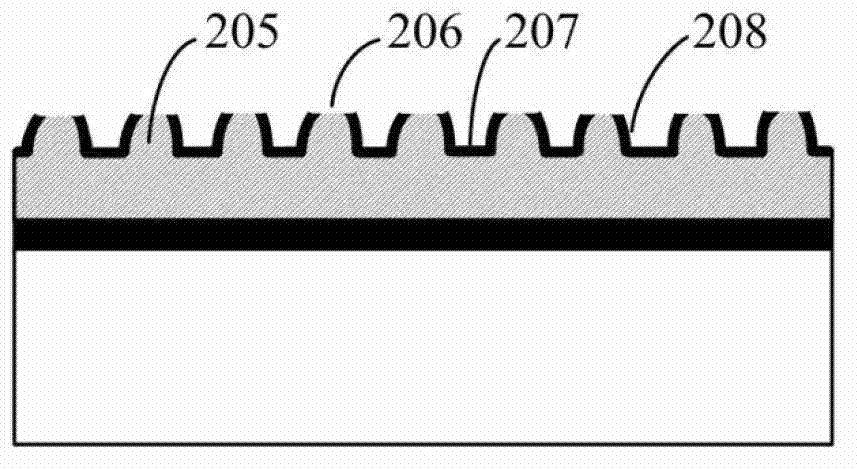

[0051] like image 3 As shown, the silicon substrate grown with two layers of material was put into RF power of 350W, Cl 2 In the cavity of the reactive ion etching machine with the H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com