Analytical method for contact performance of junction surface containing microcosmic surface shape

A technology of surface morphology and contact performance, applied in image data processing, special data processing applications, instruments, etc., can solve the problem of inability to fit the contact state of the asperities on the joint surface, affect the performance accuracy of the joint surface, and have not yet achieved rough surface contact Performance simulation analysis and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

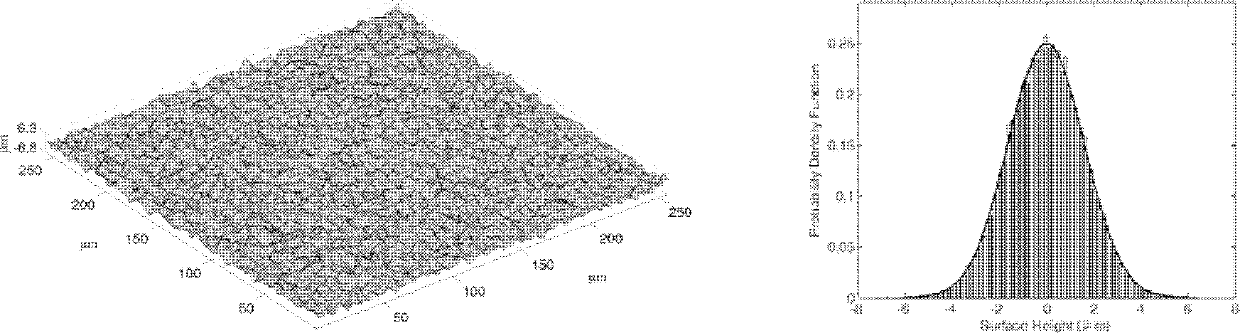

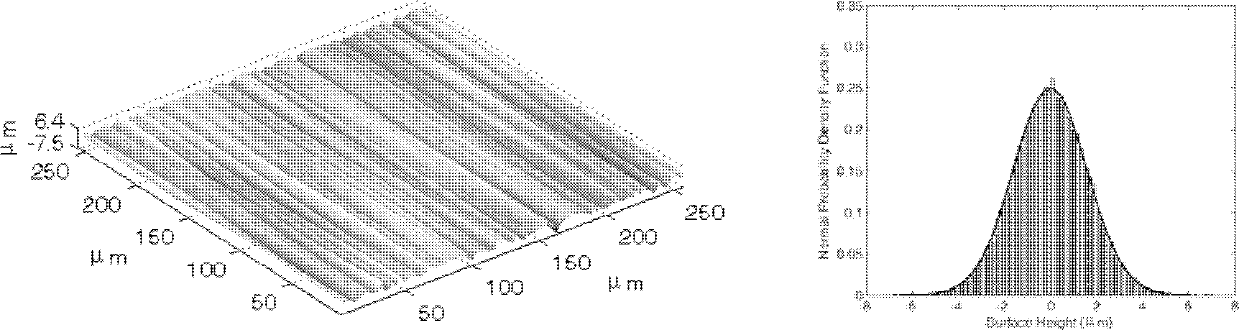

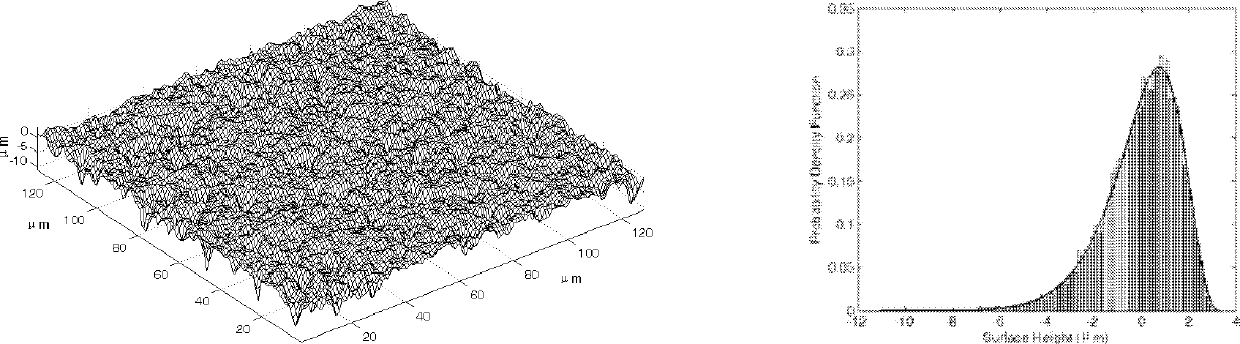

[0057] Taking the digital simulation of 3D Gaussian and non-Gaussian rough surfaces satisfying certain statistical characteristics such as autocorrelation function, standard deviation, skewness and kurtosis as an example, the microscopic surface topography acquisition method of the present invention is described; a group of Gaussian Taking surface topography contact as an example, ANSYS finite element software is used to describe the method for building and analyzing the contact performance model of the joint surface of the present invention.

[0058] 1. Acquisition of microscopic surface topography:

[0059] The Gaussian or non-Gaussian rough surface is obtained by using the three-dimensional topography simulation method, and the height matrix of the 3D rough surface topography is extracted as Z(m, n), where m and n represent the number of points in the x and y directions respectively. The specific steps are as follows:

[0060] (1) Using the three-dimensional shape simulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com