Tackifier and production method thereof

A production method and a tackifier technology, which are applied in the directions of adhesives, polymer adhesive additives, adhesive additives, etc., can solve the problems of unsatisfactory stability and cohesive force, achieve good economic benefits, increase the selling price, Excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

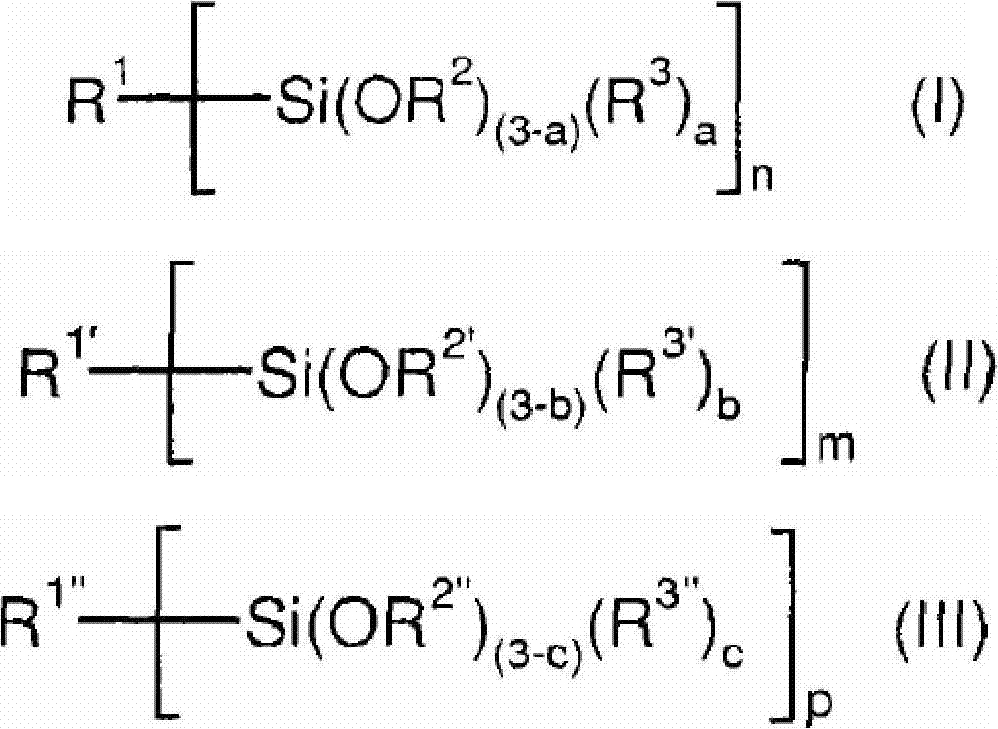

Method used

Image

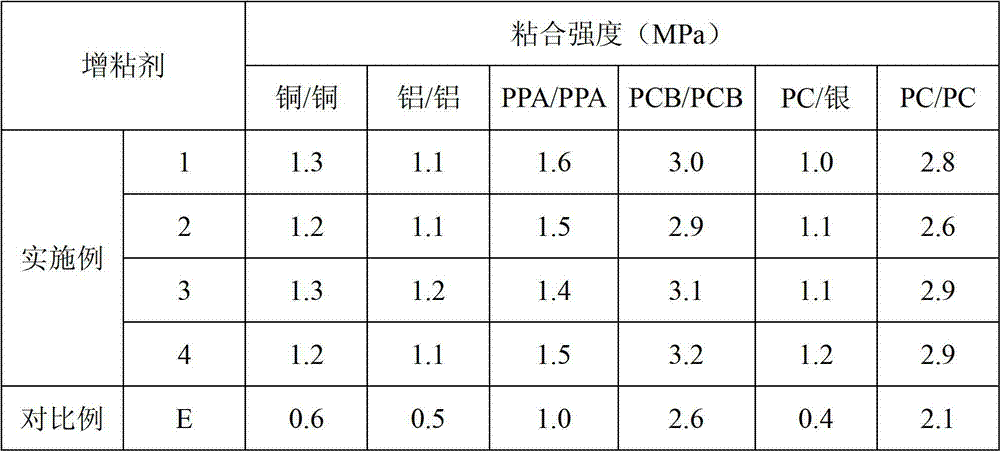

Examples

Embodiment 1

[0053] Present embodiment raw material and proportioning ratio as shown in table 1:

[0054] Table 1

[0055] raw material name

Specification

Recipe (g)

1 hydroxy silicone oil

N=6~8

600

2KH570

≥97%

62

3KH560

≥97%

174.6

4 organic tin

0.6

[0056] Steps

[0057] (1) Put raw materials 1 and 3 into a 2-liter four-necked glass reaction bottle with speed-adjustable stirring, a thermometer, and a reflux condenser, and start stirring (the speed is 250-300 rpm);

[0058] (2) Turn on the cooling water of the condenser tube and heat up. When the temperature of the material reaches 40°C, drop the organotin into the reaction bottle with a dropper. After stirring evenly, add the material 2 dropwise with a constant pressure funnel. 30 minutes to finish dripping;

[0059] (3) After dripping, insulate and react at 50±2°C for 0.5 hours;

[0060] (4) Disassemble the condenser tube, connect the...

Embodiment 2

[0063] (1) Put 500 parts by weight of hydroxy silicone oil and 230 parts by weight of KH560 into a 2-liter four-necked glass reaction bottle with speed-adjustable stirring, a thermometer, and a reflux condenser, and start stirring (the speed is 200 rpm);

[0064] (2) Turn on the cooling water of the condenser and heat up. When the temperature of the material reaches 35°C, drop 0.2 parts by weight of organic tin into the reaction bottle with a dropper. After adding 70 parts by weight of KH570 dropwise;

[0065] (3) After dropping, keep it warm at 40°C for 0.6 hours;

[0066] (4) Remove the condenser tube, connect the vacuum tube, and remove the low boiling matter at -0.001MPa for 1.5 hours;

[0067] (5) Stop the vacuum, continue the reaction for 0.3 hours, stop heating, cool down naturally, and discharge the material after reaching room temperature.

Embodiment 3

[0069] (1) Put 700 parts by weight of hydroxy silicone oil and 120 parts by weight of KH560 into a 2-liter four-necked glass reaction bottle with speed-adjustable stirring, a thermometer, and a reflux condenser, and start stirring (the speed is 400 rpm);

[0070] (2) Turn on the cooling water of the condenser and heat up. When the temperature of the material reaches 45°C, drop 1.0 parts by weight of organotin into the reaction bottle with a dropper. After adding 50 parts by weight of KH570 dropwise;

[0071] (3) After dripping, keep warm at 60°C for 0.3 hours;

[0072] (4) Disassemble the condenser pipe, connect the vacuum pipe, and remove the low boiling matter at -0.005MPa for 0.5 hours;

[0073] (5) Stop the vacuum, continue the reaction for 0.5 hours, stop heating, cool down naturally, and discharge the material after reaching room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com