Scour and corrosion resistant anti-drop ceramic abrasion-resisting structure

A corrosion-resistant and erosion-resistant technology, applied in the direction of ceramic layered products, layered products, chemical instruments and methods, etc., can solve the problems of ceramic fragmentation, easy falling off, wear and tear due to environmental temperature changes, and avoid the expansion of the gap between ceramic parts , high comprehensive economic benefits, and the effect of improving quality and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

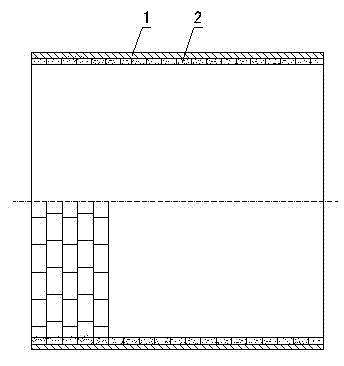

[0024] Embodiment 1, as Figure 1-3 As shown, the ceramic wear-resistant structure resistant to erosion, corrosion, and falling off is a straight pipe, which is mainly composed of a metal base 1 of the pipe fitting, a ceramic component 2, and a steel reinforcement rib 3, and several welds are welded at intervals on the inner surface of the metal base 1 of the pipe fitting. The steel bar reinforcement 3 is attached to the metal substrate 1 on the side opposite to the steel bar reinforcement 3, and a ceramic component 2 composed of several ceramic sheets is attached, and the corresponding grooves of the several ceramic sheets and the steel bar reinforcement 3 are dovetail grooves; The contact surface between the ceramic component 2 and the metal base 1 is filled with a high-temperature resistant inorganic adhesive 4, and the splicing of the several rows of ceramic sheets is stepped or concave-convex splicing to form a wear-resistant layer, which mainly plays the role of supportin...

Embodiment 2

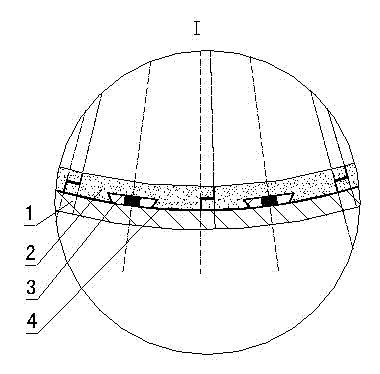

[0025] Embodiment 2, as Figure 4-7 As shown, the ceramic wear-resistant structure that is resistant to erosion, corrosion, and falling off is a wear-resistant ceramic elbow, which is mainly composed of a metal matrix 1 of large and small pipe fittings, a ceramic component 2 and a steel bar reinforcement 3. In the metal matrix 1 of the large pipe fitting The inner surface of the metal matrix 1 of the small pipe fitting or the outer surface of the metal matrix 1 of the small pipe fitting is provided with several steel reinforcement ribs 3 at intervals, and the groove corresponding to the steel reinforcement rib 3 of the metal matrix 1 of the large pipe fitting is a T-shaped groove, such as Figure 6 Shown; The groove corresponding to the steel bar reinforcing rib 3 of the metal matrix 1 of the small pipe fitting is a dovetail groove, such as Figure 7 As shown; on the metal substrate 1 opposite to the steel bar reinforcing rib 3, a ceramic component 2 spliced by several rows ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com