Sampling full digitalization current type PID (Proportion Integration Differentiation) control method and control circuit

A control method and fully digital technology, applied in the direction of manufacturing tools, arc welding equipment, welding equipment, etc., can solve the problems of low-level, lack of welding process expert system, and digital control, etc., and achieve strong controllability and work performance The effect of stabilizing and anti-inrush current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

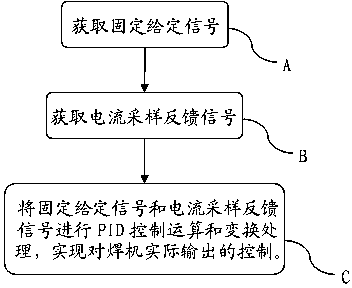

[0025] Such as figure 1 as shown in:

[0026] A sampling all-digital current-type PID control method described in an embodiment of the present invention includes the following steps:

[0027] Step A. Obtain a fixed given signal;

[0028] Step B. Obtaining a current sampling feedback signal;

[0029] Step C. Perform PID control operation on the fixed given signal and the current sampling feedback signal to obtain the duty cycle pulse width signal, and transform and process the welding current, voltage, and power data according to the duty cycle pulse width signal to realize the Control of the actual output of the welder.

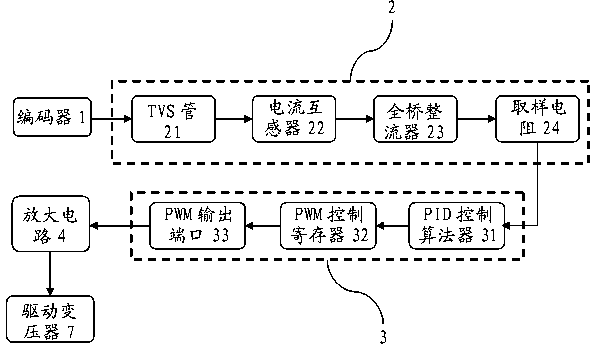

[0030] Wherein, the acquisition of the current sampling feedback signal may specifically be: using a TVS tube to absorb the sampled voltage, using a current transformer to sample the current signal of the switching tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com