Sound insulation material, sound insulation layer and its preparation method and application

A technology for sound insulation, heat insulation and thermal insulation layer, which is applied in the directions of heat insulation, sound insulation, chemical instruments and methods, etc., can solve the problems of affecting the noise reduction effect and fire performance of sound-absorbing panels, complicated production and construction processes, loss of sound insulation effect, etc. Good acid-base and anti-aging effects, good protection, heat insulation and noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

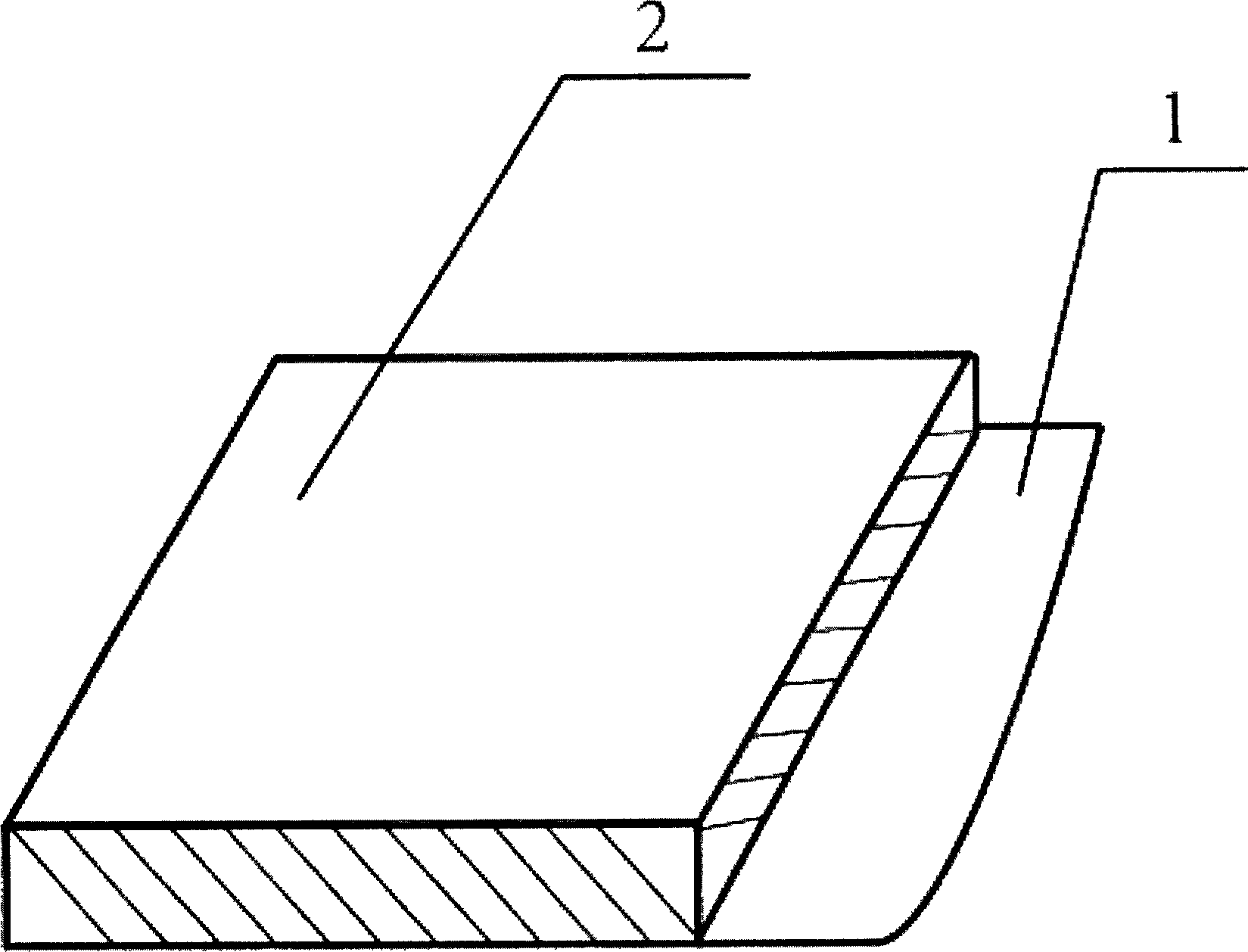

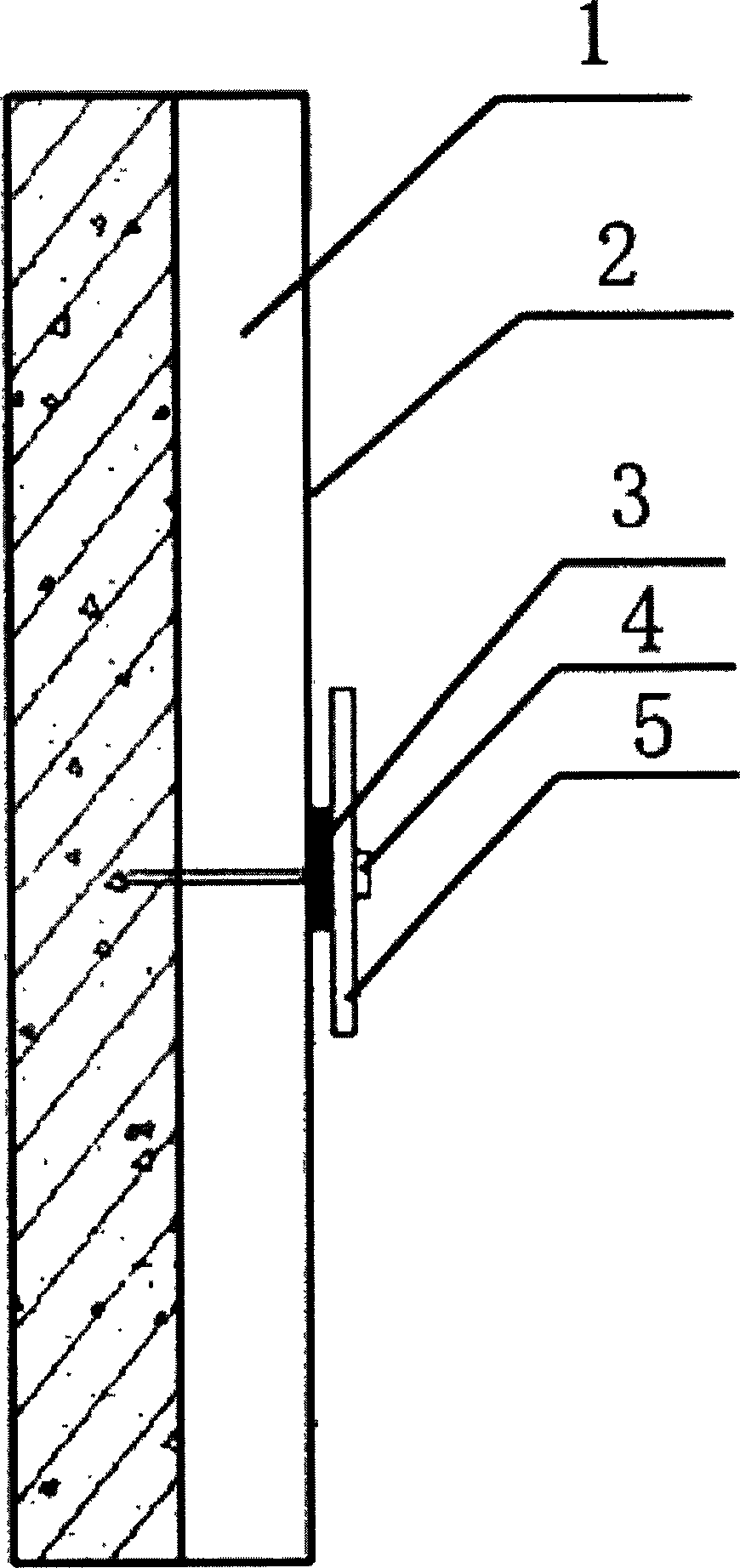

[0046] Embodiment 1: a kind of sound insulation and thermal insulation material, such as figure 1 As shown, it includes a sound-absorbing material body 1 and a surface covering layer 2, the surface covering layer is arranged on the surface of the sound-absorbing material body, and is combined with the sound-absorbing material body through an adhesive.

Embodiment 2

[0047] Embodiment 2: A sound insulation and thermal insulation material, which includes a sound-absorbing material body 1 and a surface covering layer 2, the surface covering layer 2 is arranged on the surface of the sound-absorbing material body 1, and is combined with the sound-absorbing material body through an adhesive. Among them, the sound-absorbing material main body 1 is made of glass fiber needled felt or glass fiber needled board, with a thickness of 10mm-50mm and a density of 60-180kg / m 3 , wherein the glass fibers in the main body of the sound-absorbing material include glass fibers of two different diameters, one is thick glass fibers with a diameter of 12-15 μm, and the other is thin glass fibers with a diameter of 5-10 μm. The weight mixing ratio of glass fiber is 30-70:70-30, and the length of thick glass fiber is 40-80mm, and the length of fine glass fiber is 40-80mm. The combination of disordered and interlaced ways presents an unoriented three-dimensional mi...

Embodiment 3

[0048] Embodiment 3: For the sound insulation and thermal insulation material in Embodiment 2, the thickness of the sound-absorbing material body is 20-30mm, by comparing with 60mm rock wool materials, during the experiment, use glass fiber needle felt or glass fiber needle felt The noise reduction effect of the board is obvious, and its daytime index can reach below 37 decibels, and the nighttime index can reach below 33 decibels.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com